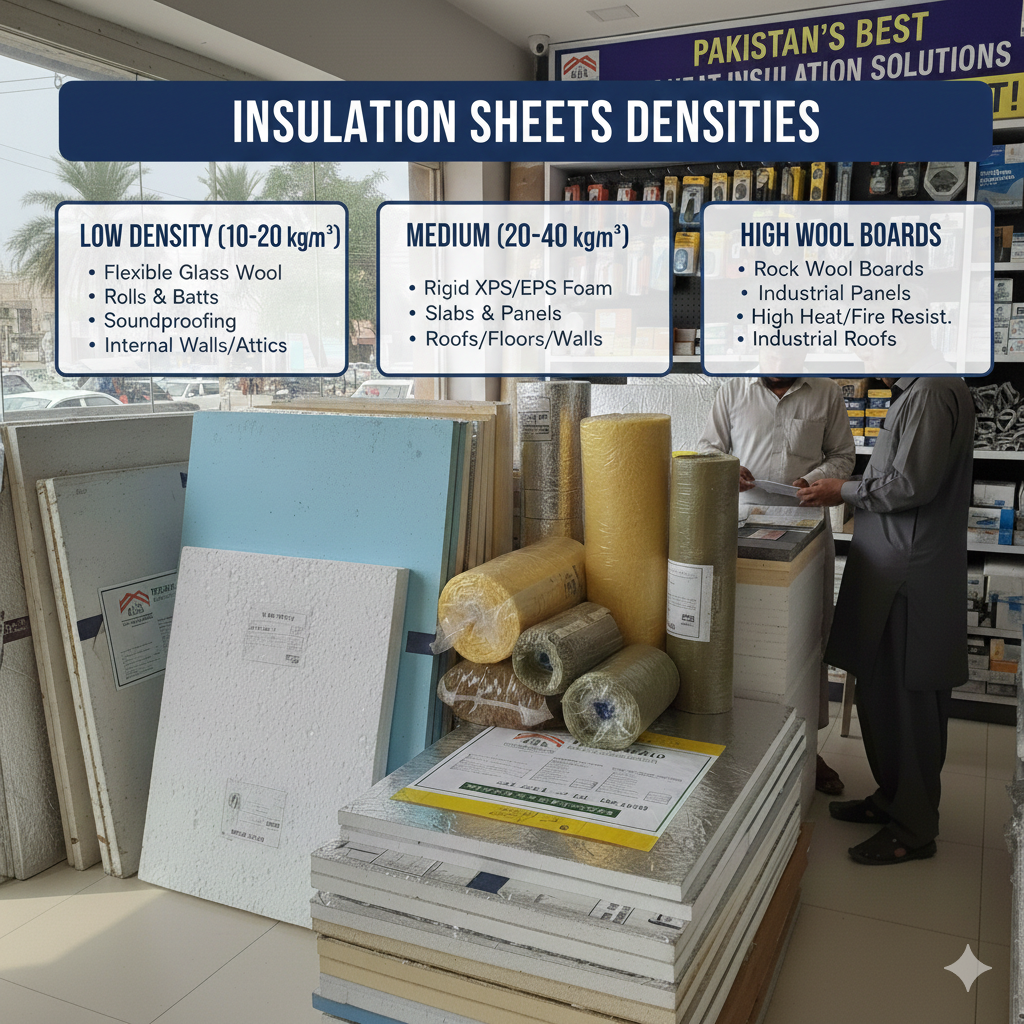

When selecting insulation for buildings in Pakistan, material type alone is not enough. Insulation density plays a critical role in thermal performance, durability, and suitability for specific applications. However, understanding insulation sheet densities helps builders and homeowners choose the right product for roofs, walls, and industrial systems.

Moreover, this guide explains insulation densities for EPS, XPS, rockwool, glasswool, and aluminium foil, along with practical recommendations for different building needs.

Why Insulation Density Matters

Insulation density refers to the weight of material per cubic meter. It directly affects strength, heat resistance, and long-term performance. However, choosing the wrong density can result in poor insulation, compression, or reduced lifespan.

Furthermore, understanding insulation density kg/m3 ensures the insulation performs as intended under real-world conditions.

Types of Insulation Materials Used in Buildings

Modern construction uses multiple types of insulation material depending on thermal, acoustic, and structural requirements. Below is a practical overview of common materials used in Pakistan.

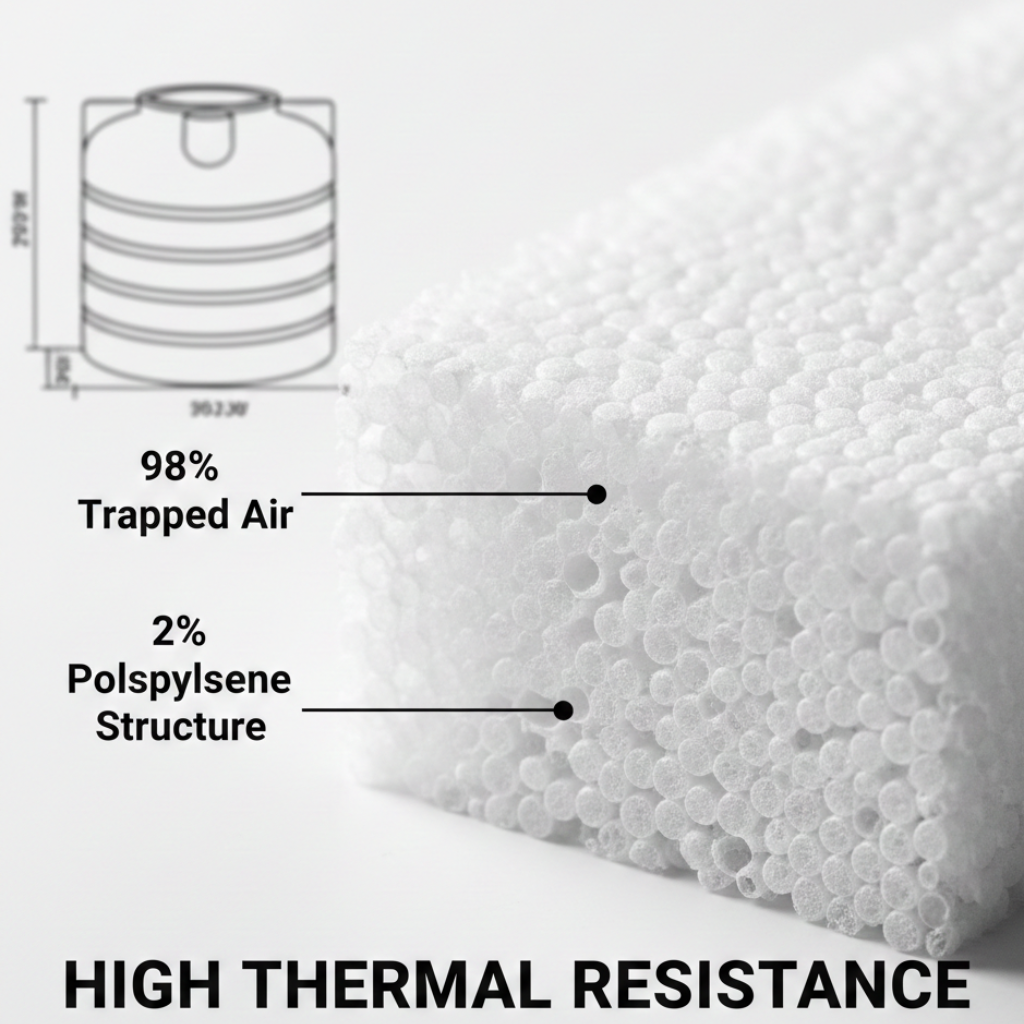

Expanded Polystyrene (EPS) Density Explained

EPS is a lightweight insulation material widely used in walls and floors. It provides good thermal resistance while remaining cost-effective.

Typical density range:

- Low-density EPS for residential walls

- Medium-density EPS for floors and partitions

EPS is part of the broader thermal insulation materials in building applications due to its ease of installation and affordability.

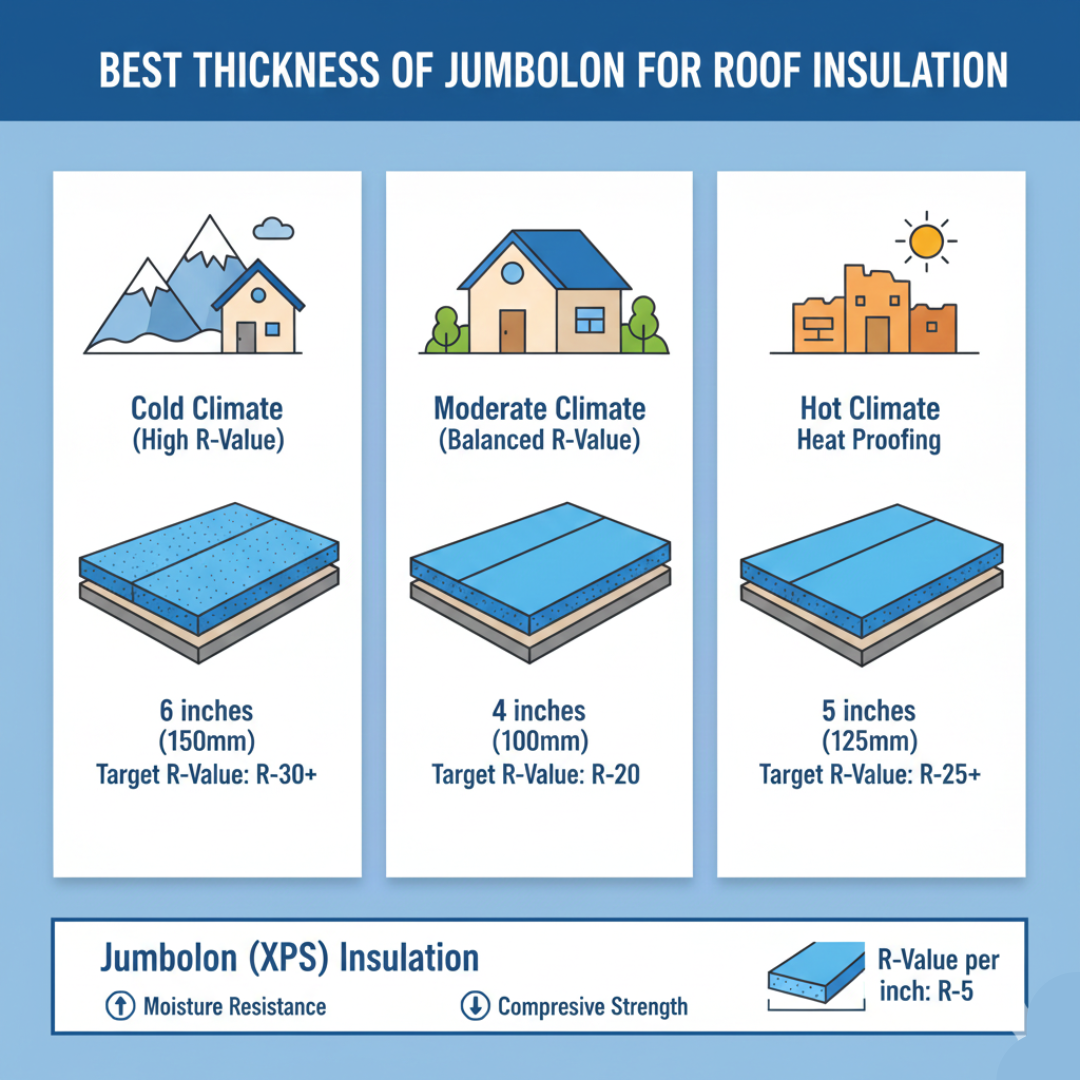

Extruded Polystyrene (XPS) Density Explained

XPS insulation is denser than EPS and offers higher compressive strength and moisture resistance. It is often used in roofs, basements, and exterior walls.

Because of its structure, XPS performs well as a hot insulation material in areas exposed to direct sunlight and moisture.

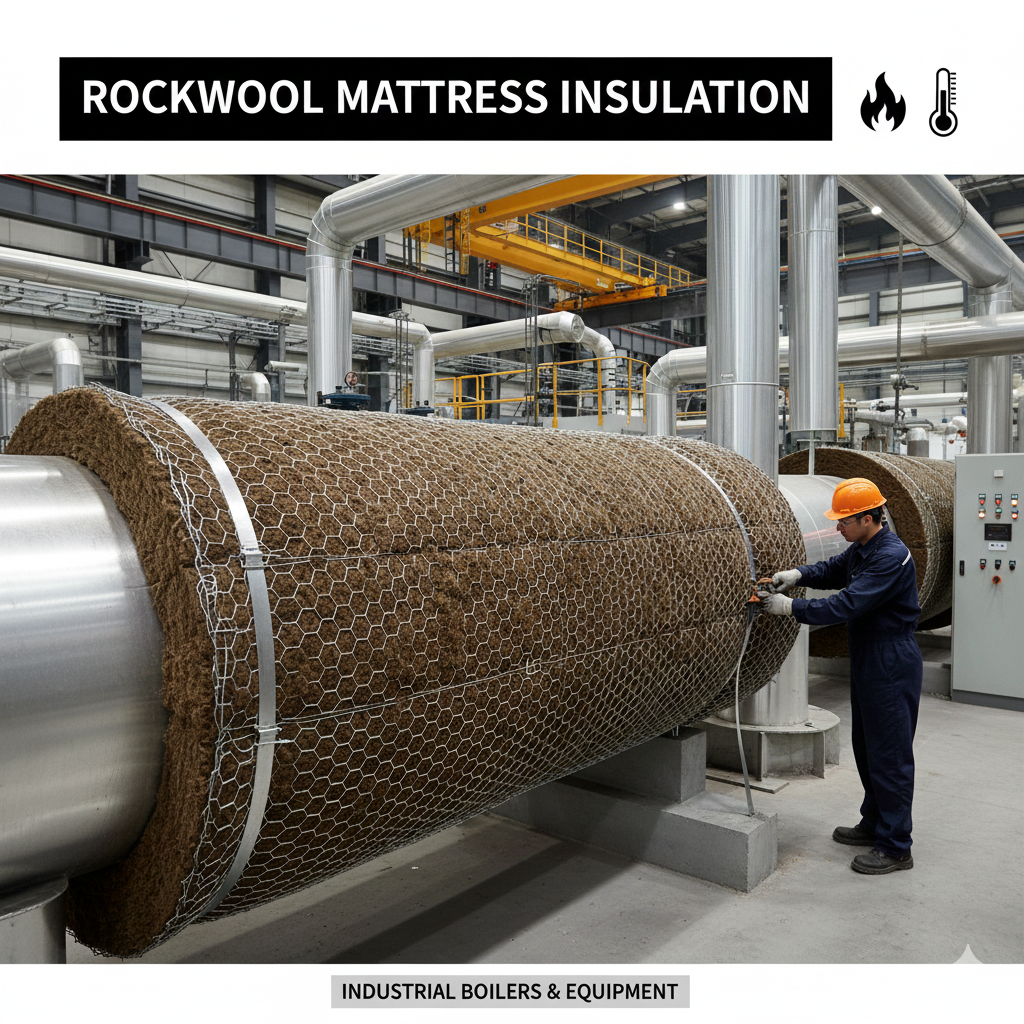

Rockwool Insulation Density Overview

Rockwool insulation is known for fire resistance and sound absorption. Selecting the correct rockwool insulation density kg/m3 is essential for achieving optimal performance.

Lower densities are used for acoustic insulation, while higher densities are suitable for industrial and fire-rated applications.

Rockwool is commonly selected as a best heat insulation material for commercial and industrial buildings due to its thermal stability.

Glasswool Insulation Density Explained

Glasswool insulation offers excellent thermal and acoustic performance at relatively low weight. It is commonly used in ceilings, HVAC ducts, and interior walls.

Lower densities suit ceiling applications, while medium densities are preferred for partitions and ducts within thermal insulation materials in building systems.

Aluminium Foil Insulation and Density Concept

Unlike fibrous insulation, aluminium foil does not rely on density to resist heat. Instead, it reflects radiant heat. When combined with foam or fiber insulation, it enhances overall performance.

However, aluminium foil is often paired with other insulation materials to create layered systems for maximum efficiency.

Insulation Density Chart (General Overview)

An insulation density chart helps compare materials and applications:

- EPS: Low to medium density

- XPS: Medium to high density

- Rockwool: Medium to high density

- Glasswool: Low to medium density

- Aluminium foil: Reflective layer (non-density based)

However, this chart simplifies material selection based on structural and thermal needs.

Thermal Insulation Materials List for Practical Use

A practical thermal insulation materials list for buildings includes:

- EPS boards

- XPS boards

- Rockwool slabs

- Glasswool rolls

- Aluminium foil insulation

Moreover, each material serves a specific purpose based on density, location, and performance requirements.

Choosing the Best Heat Insulation Material by Density

The best heat insulation material is not defined by density alone. Roofs require different density levels than walls or industrial pipelines.

For example:

- Low density works for ceilings and partitions

- Medium density suits residential walls

- High density is required for industrial and fire-rated zones

However, matching density to application ensures long-term insulation efficiency.

Conclusion

Understanding insulation sheet densities is essential for selecting the right insulation material in Pakistan. EPS, XPS, rockwool, glasswool, and aluminium foil each offer unique benefits when used at appropriate density levels.

Moreover, by considering insulation density alongside application requirements, builders and homeowners can achieve better thermal comfort, energy savings, and durability.’

FAQ’S

Insulation density kg/m³ refers to the weight of insulation material per cubic meter. Higher density usually offers better strength and durability, while lower density is suitable for lightweight applications like ceilings.

Medium-density insulation is generally best for residential buildings as it balances thermal performance, durability, and cost for walls and roofs.

Rockwool insulation density kg/m³ affects fire resistance, sound absorption, and thermal stability. Higher density is recommended for industrial and fire-rated applications.

Aluminium foil insulation does not rely on density for performance. It works by reflecting radiant heat and is usually combined with other insulation materials.

Leave a Reply