Poultry farming is one of the fastest-growing agricultural sectors in Pakistan, but it is also one of the most temperature-sensitive. Heat stress in summer and cold exposure in winter can severely affect bird health, feed conversion ratio, and mortality rates. This is where Insulation for Poultry Farms plays a critical role.

Proper insulation helps poultry farmers maintain a stable internal environment, reduce energy costs, and improve overall farm productivity. In this guide, we will explore why insulation matters, suitable materials, local considerations, and how to choose the best insulation for poultry farms in Pakistan.

Why Insulation Is Essential for Poultry Farms

Birds are highly sensitive to temperature changes. Even small fluctuations can cause stress, reduce egg production, and increase disease risk.

Key benefits of proper insulation include:

- Stable internal shed temperature

- Reduced dependency on heaters and exhaust fans

- Lower electricity and fuel costs

- Improved bird growth and feed efficiency

- Reduced mortality during extreme weather

For these reasons, insulation for poultry farms in Pakistan is no longer optional—it is a necessity for modern, profitable farming.

Climate Challenges for Poultry Farms in Pakistan

Pakistan’s climate varies from region to region, but extreme heat remains a nationwide concern.

Common challenges include:

- Summer temperatures exceeding 45°C

- High humidity in coastal and central regions

- Cold winter nights in northern areas

- Sudden temperature drops during monsoon rains

Without insulation, poultry sheds absorb external heat during the day and lose warmth rapidly at night, creating stress cycles for birds.

How Insulation Works in Poultry Sheds

Insulation acts as a thermal barrier between the external environment and the internal shed space. It slows down heat transfer in both directions:

- In summer: Keeps external heat out

- In winter: Retains internal warmth

This thermal stability allows ventilation systems to work efficiently without overloading heaters or cooling equipment.

Best Insulation Materials for Poultry Farms

Choosing the right material is crucial. The best insulation for poultry farms depends on climate, shed design, and budget.

Commonly Used Insulation Options

1. Expanded Polystyrene (EPS)

Lightweight and cost-effective, EPS is commonly used for walls and ceilings in poultry sheds.

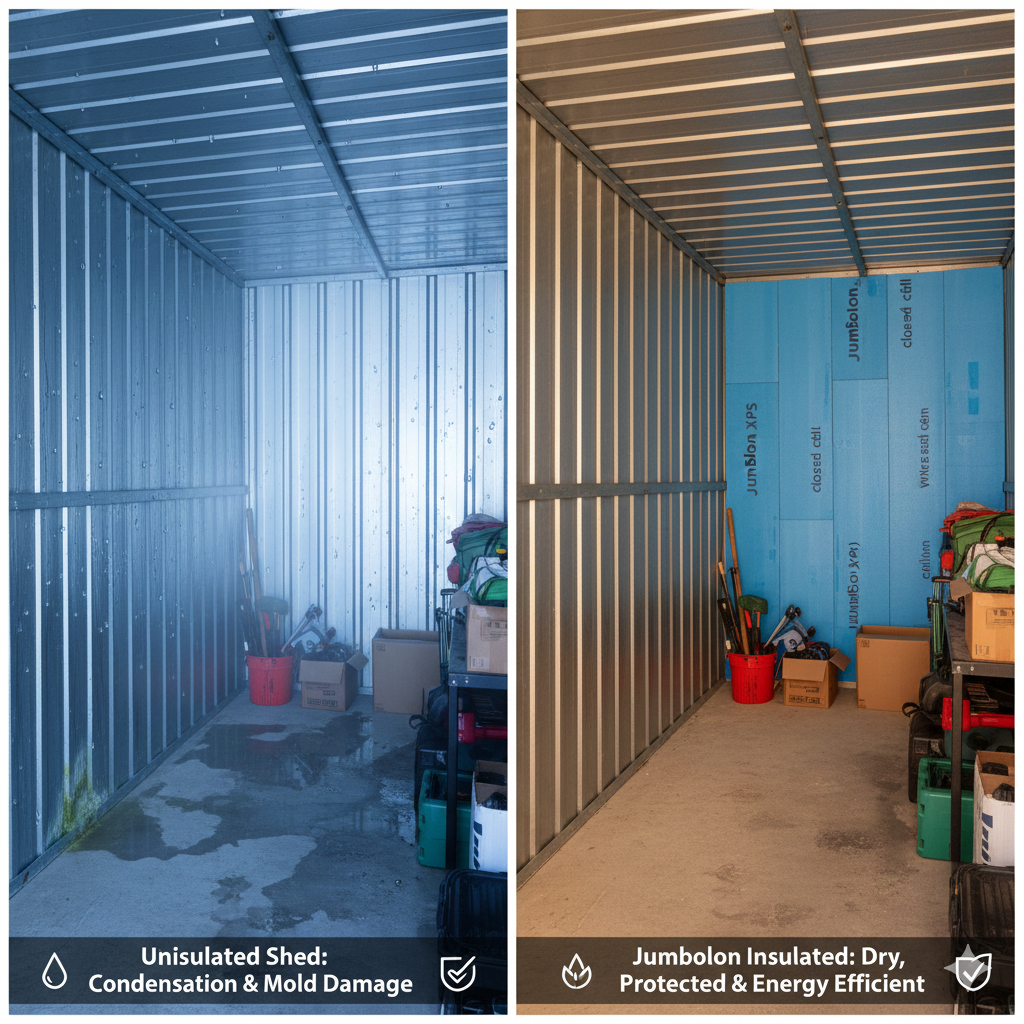

2. Extruded Polystyrene (XPS)

Provides better moisture resistance and higher insulation performance, suitable for humid areas.

3. Jumbolon / Foam Sheets

Flexible and easy to install, often used for roof insulation.

4. Rockwool (Mineral Wool)

Excellent for heat and sound insulation, especially in commercial-scale poultry operations.

Each material offers different performance levels, so selection should be based on farm requirements rather than price alone.

Roof vs Wall Insulation in Poultry Farms

Roof Insulation

The roof receives the most direct heat exposure. Insulating the roof alone can reduce internal shed temperatures significantly during peak summer hours.

Wall Insulation

Walls help maintain temperature consistency, especially during nighttime cooling and winter seasons.

For best results, professional poultry farms insulate both roofs and walls.

Technical Comparison Table – Poultry Farm Insulation Materials

| Insulation Material | Heat Reduction | Moisture Resistance | Fire Resistance | Typical Poultry Farm Use |

|---|---|---|---|---|

| EPS Sheets | Good | Medium | Low | Walls, ceilings |

| XPS Boards | Very High | High | Medium | Roofs, humid areas |

| Jumbolon Foam | Medium | Medium | Low | Roof lining |

| Rockwool Insulation | High | Medium | Very High | Commercial poultry sheds |

Note: Material selection should match ventilation design, climate conditions, and operational scale.

Installation Considerations for Poultry Farms

When installing insulation, attention to detail is critical.

Important points include:

- Proper sealing to prevent air leakage

- Moisture resistance to avoid fungal growth

- Safe material placement away from birds

- Compatibility with ventilation systems

Incorrect installation can reduce insulation efficiency by up to 40%.

Insulation for Poultry Farms Price in Pakistan

The insulation for poultry farms price in Pakistan varies based on several factors:

- Type of insulation material

- Thickness and density

- Total covered area

- Installation method

- Location of the farm

While initial costs may seem high, insulation significantly reduces long-term expenses by lowering energy consumption and improving flock performance. Most farms recover insulation costs within a few production cycles.

Economic Benefits of Insulating Poultry Farms

Insulation is an investment, not an expense.

Long-term benefits include:

- Lower electricity bills

- Reduced fuel usage for heating

- Improved feed conversion ratios

- Higher weight gain in broilers

- More consistent egg production

These factors directly impact profitability, making insulation a smart financial decision.

Common Mistakes to Avoid

Many farmers make avoidable mistakes when choosing insulation:

- Selecting material based only on price

- Ignoring moisture resistance

- Poor-quality installation

- Not insulating ventilation gaps

- Using non-agricultural-grade materials

Avoiding these errors ensures better performance and longer insulation life.

Is Insulation Suitable for Small Poultry Farms?

Yes. Insulation is beneficial for both small and large poultry operations. Even partial insulation (roof-only) can dramatically improve internal conditions in small farms, especially during summer.

Final Thoughts

Insulation for Poultry Farms is one of the most effective ways to improve bird welfare, reduce operational costs, and increase overall productivity. Given Pakistan’s challenging climate, investing in proper insulation is no longer optional—it is essential for sustainable poultry farming.

By choosing the best insulation for poultry farms, ensuring correct installation, and understanding local climate needs, farmers can achieve consistent performance throughout the year.

FAQ’S

Insulation helps maintain a stable shed temperature, reducing heat stress in summer and heat loss in winter. This improves bird health, feed efficiency, and overall farm profitability in Pakistan’s extreme climate.

The best insulation for poultry farms depends on climate and budget. EPS and XPS are commonly used for thermal control, while rockwool is preferred where fire resistance and sound control are required.

Yes, insulation significantly reduces electricity costs by minimizing the load on fans, coolers, and heaters, especially during peak summer and winter seasons.

Yes, even small poultry farms benefit from roof or partial insulation, which can noticeably reduce internal temperatures and improve bird comfort.

Insulation for poultry farms price varies based on material type, thickness, and covered area. While initial costs differ, long-term savings usually outweigh the investment.

Leave a Reply