The Challenge: Protecting Assets Worth Millions in Transit

Moving industrial equipment—be it specialized robotics, delicate electronic control units, or large engine components—is an exercise in high-stakes logistics. These assets represent significant capital investment, and the journey from the factory floor to the installation site is fraught with risks: rough handling, sudden impacts, temperature extremes, and moisture exposure. Moreover, a failure in packaging can lead to catastrophic transit damage, resulting in costly delays, repairs, and reputational harm.

Furthermore, this is where EPS sheet for industrial machinery packaging steps in as the most reliable, practical, and cost-effective solution. Known globally as Expanded Polystyrene Foam, Moreover, EPS offers a unique suite of properties that make it ideally suited for the rigorous demands of industrial shipping.

The Science of Protection – Shock and Vibration Control

The primary function of industrial packaging is to neutralize the kinetic energy generated during transport. EPS excels at this job due to its intrinsic cellular structure.

Superior Shock Absorption

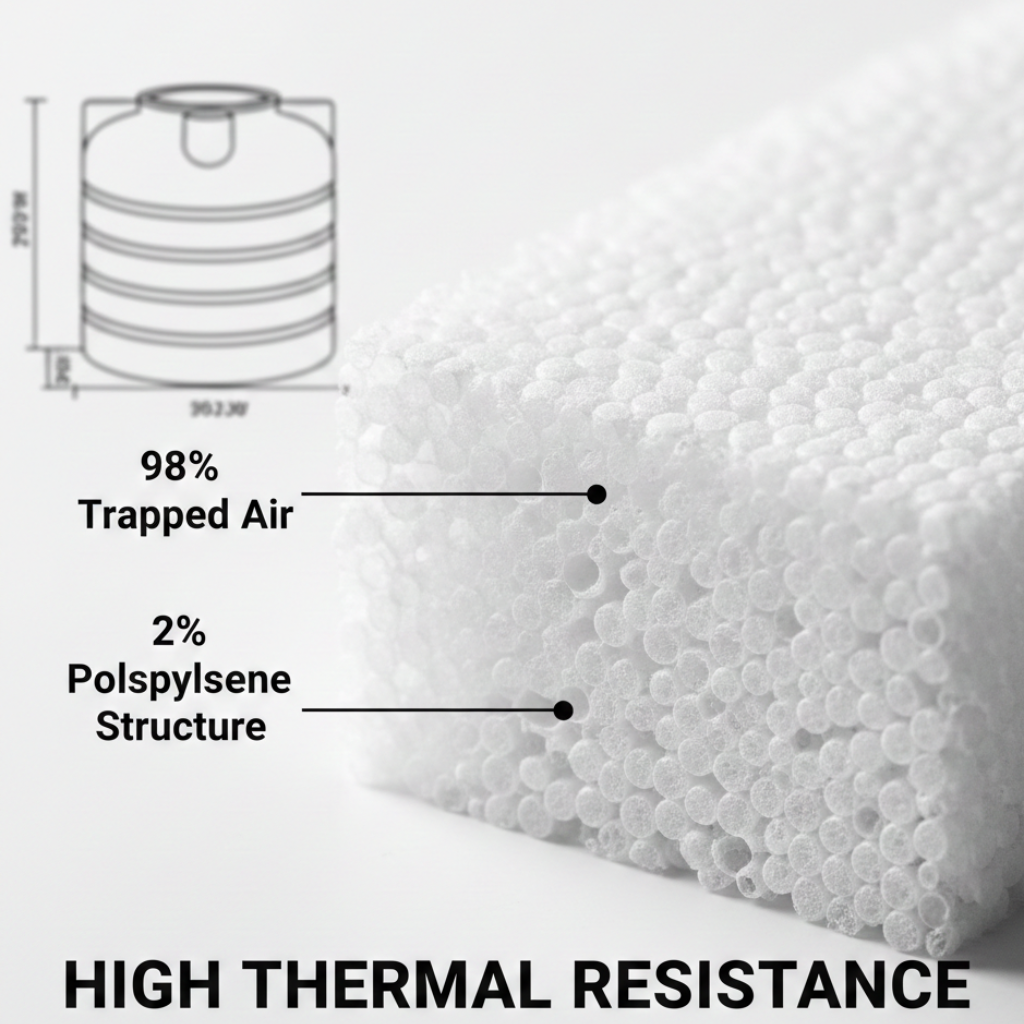

Expanded Polystyrene Foam is composed of millions of tiny, closed cells filled with air. When subjected to sudden force or impact, these air pockets compress and deform, distributing the load over a larger area and absorbing the energy. This remarkable shock absorption capability is essential for safeguarding sensitive components within heavy machinery from drops, jolts, and collisions. The material effectively acts as a crumple zone, dissipating impact energy before it reaches the delicate equipment.

Unmatched Vibration Dampening

Beyond single impacts, machinery is constantly subjected to sustained, low-level vibration from truck engines, rail lines, or ship movement. This continuous shaking can loosen fasteners, damage soldered joints, and cause electronic components to fail. Moreover, the viscoelastic properties of EPS provide excellent vibration dampening, isolating the machinery from these harmful frequencies. By reducing resonant vibrations, the lifespan of the packaged asset is preserved, ensuring it arrives ready for immediate operation and reducing the likelihood of hidden transit damage.

Precision Engineering and Load Management

Generic packaging cannot protect complex industrial equipment. The effectiveness of EPS is maximized through engineering precise, functional designs.

Custom-Fit Packaging Solutions

Industrial assets rarely come in standard shapes. The beauty of EPS sheet is its versatility and manufacturability. It can be easily cut, routed, molded, and laminated to create custom-fit packaging solutions that cradle the exact contours of the machinery. Moreover, this precision fit ensures that the product is held securely, preventing shifting, rubbing, and localized stress points. A custom design is critical for achieving optimal shock absorption and eliminating empty space within the crate.

Strategic Load Distribution

Protecting heavy machinery requires more than just filling gaps, it requires strategically managing its immense weight. High-density Expanded Polystyrene Foam can be engineered to support substantial weight, ensuring proper load distribution across the package base and minimizing pressure points that could damage the machine’s casing or frame. However, by spreading the weight evenly, EPS prevents deformation of the corrugated box or wooden crate, maintaining the integrity of the entire shipping container. This strategic use of EPS is vital for safely stacking and handling large packages.

Environmental and Durability Benefits of EPS

The advantages of EPS sheet for industrial machinery packaging extend to environmental protection and material endurance in harsh shipping conditions.

Moisture Resistance for Global Shipping

Industrial goods often travel across continents, enduring drastic changes in climate, humidity, and often, sea spray. The moisture resistance of EPS is paramount here. Since the material is comprised of non-interconnected, closed cells, it does not absorb water. However, this ensures that the cushioning material maintains its integrity and vital cushioning properties even in damp environments, preventing water damage and corrosion to the packaged metal or electronic components.

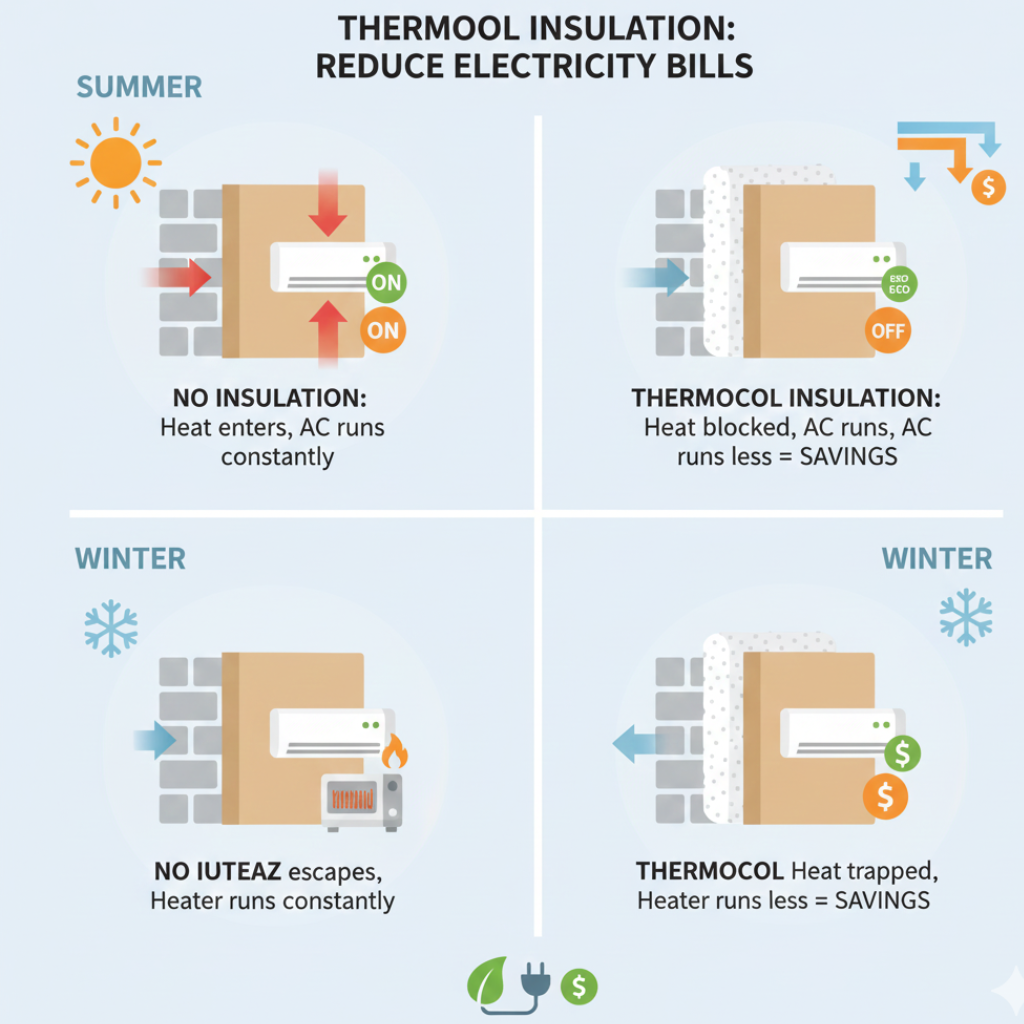

Maintaining Thermal Stability

For certain sensitive components or chemical products shipped alongside the machinery, maintaining a consistent temperature is essential. Moreover, EPS provides exceptional thermal stability, acting as an insulator to shield the contents from external heat spikes or freezing temperatures. While not a replacement for refrigerated containers, this thermal barrier adds a vital layer of protection against rapid environmental shifts during loading and unloading, contributing to the overall quality control of the shipment.

A Recyclable Material

In an era of increased corporate responsibility, using a recyclable material is an important consideration. Expanded Polystyrene Foam is $100%$ recyclable. Forward-thinking companies are increasingly establishing reverse logistics to collect and recycle used EPS packaging. Moreover, it often densifying it before shipment to recycling centers. Choosing EPS demonstrates a commitment to sustainable practices. While still benefiting from its superior performance as a cost-effective solution to packaging.

Conclusion: EPS as the Standard for Industrial Integrity

The use of EPS sheet for industrial machinery packaging is no longer a luxury. It is the industry standard for robust protection. From its excellent shock absorption and vibration dampening capabilities to its essential moisture resistance and thermal stability. Moreover, EPS provides a multilayered defense against the stresses of global logistics.

Furthermore, by utilizing custom-fit packaging and ensuring proper load distribution, manufacturers guarantee the safe arrival of their heavy machinery. The fact that EPS is a recyclable material and a genuinely cost-effective solution further solidifies its position. As the indispensable material for maintaining asset integrity and minimizing expensive transit damage throughout the supply chain. The superior cushioning properties of EPS ensure that protection never comes second to profit.

FAQ’S

Expanded Polystyrene Foam (EPS) has a unique closed-cell structure where $98\%$ of its volume is trapped air. When the packaging experiences an impact or shock, the individual EPS beads and their internal air pockets compress momentarily. This compression action absorbs and disperses the kinetic energy across the entire sheet, preventing concentrated force from reaching the heavy machinery. This reliable shock absorption mechanism is essential for mitigating costly transit damage.

Vibration dampening refers to the ability of the EPS sheet to isolate the packaged machinery from continuous, low-level shaking (vibration) generated by truck engines, trains, or ships. These sustained vibrations can cause internal damage, loosen components, and lead to premature failure. The inherent viscoelastic properties of the Expanded Polystyrene Foam cushion and absorb these frequencies, ensuring the long-term thermal performance of the equipment isn’t compromised by unnecessary movement. This proactive vibration dampening ensures the machinery arrives in optimal working condition.

EPS sheet is highly versatile and can be processed using heat-cutting, CNC milling, or molding techniques to create precise, custom-fit packaging inserts. These inserts are engineered to match the exact contours and stress points of the machinery. By distributing the weight evenly across the entire packaged item, the foam ensures efficient load distribution. This prevents concentrated pressure from building up on sensitive points, maximizing the effectiveness of the cushioning properties and significantly reducing the risk of structural failure or transit damage.

Yes. While the upfront cost of Expanded Polystyrene Foam may be slightly higher than simple cardboard or basic wrapping, it provides exceptional value as a cost-effective solution due to its prevention of loss. Its superior moisture resistance protects valuable heavy machinery from corrosion and water damage encountered during global shipping, maintaining the integrity of the package even in humid conditions. This durability ensures the packaging doesn’t degrade, thereby guaranteeing reliable shock absorption and eliminating the far greater costs associated with machinery replacement, repairs, and logistical delays caused by transit damage.