Introduction

When planning any home insulation project, whether it’s for thermal comfort, energy efficiency, or acoustic insulation, one of the most fundamental decisions you’ll make is choosing the right insulation thickness. For Glasswool (fiberglass), this choice directly impacts its thermal performance and, consequently, your long-term energy savings.

This comprehensive Glasswool thickness guide will walk you through the common range of $25 \, \text{mm}$ to $100 \, \text{mm}$, explaining how each thickness affects the insulation R-value, its ideal applications, and crucial considerations for making the best choice for your building material needs.

Understanding R-Value and Its Relation to Thickness

Before diving into specific thicknesses, it’s vital to grasp the concept of insulation R-value. R-value measures a material’s resistance to heat flow. A higher R-value indicates better insulating properties.

For Glasswool, the R-value is directly proportional to its thickness. Doubling the thickness generally doubles the R-value, leading to improved thermal performance. This is why selecting the appropriate Glasswool thickness is paramount for achieving desired energy efficiency.

Glasswool Thickness Options and Their Applications

Let’s explore the common thicknesses of Glasswool insulation blanket available in the market:

1. 25mm Glasswool (1 Inch)

- R-value (Approximate): R-1.1 to R-1.5

- Ideal Applications:

- Soundproofing: Often used as an additional layer for acoustic insulation in internal wall partitions or false ceilings where minimal thermal insulation is required, but sound dampening is a priority.

- Duct Insulation: Wrapping HVAC ductwork to prevent heat loss/gain and reduce noise.

- Limited Space: Where space is extremely constrained, and any insulation is better than none.

- Consideration: This is generally considered a minimal Glasswool thickness and is rarely sufficient for primary home insulation where significant energy efficiency is desired.

2. 50mm Glasswool (2 Inches)

- R-value (Approximate): R-2.2 to R-3.0

- Ideal Applications:

- Internal Walls: Excellent for acoustic insulation between rooms or floors.

- Existing Wall Cavities: Often chosen for older homes or retrofits where wall cavities are shallow, making it a common wall insulation choice.

- Floor Insulation: Effective under timber floors or in crawl spaces for basic thermal performance.

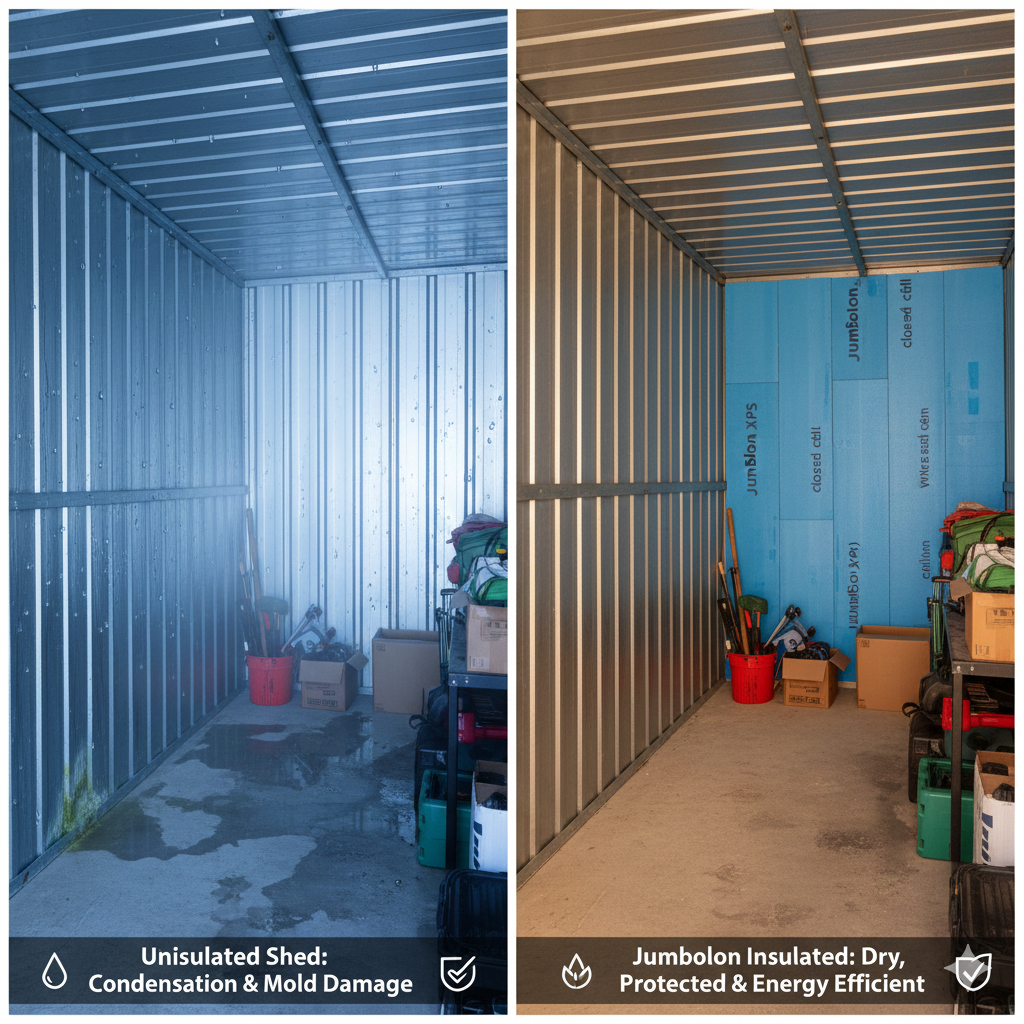

- Shed or Garage Insulation: Provides a good balance of cost and insulation for non-living spaces.

- Consideration: A very versatile Glasswool thickness for secondary insulation or in moderate climates, but may still be insufficient for primary roof insulation or in extreme climates.

3. 75mm Glasswool (3 Inches)

- R-value (Approximate): R-3.3 to R-4.5

- Ideal Applications:

- Exterior Wall Insulation: A good choice for modern exterior wall insulation, providing a substantial boost to thermal performance.

- Residential Roof Insulation: Can be used in conjunction with other layers or as a primary layer for roof insulation in moderately insulated attics.

- Ceiling Insulation: Provides effective thermal insulation for ceilings below conditioned spaces.

- Consideration: This Glasswool thickness offers a strong balance between performance and cost, making it a popular choice for many new construction projects seeking improved energy efficiency.

4. 100mm Glasswool (4 Inches)

- R-value (Approximate): R-4.4 to R-6.0

- Ideal Applications:

- Primary Roof Insulation: Ideal for high-performance roof insulation in attics and lofts, especially in regions with extreme temperatures.

- Exterior Walls in Cold Climates: Provides maximum thermal performance for wall insulation in colder regions, ensuring superior energy efficiency.

- Soundproofing Studios: Used for optimal acoustic insulation in home theaters or recording studios due to its density and thickness.

- Floor Insulation (Over crawlspaces/unheated basements): Prevents significant heat loss through the floor.

- Consideration: This is the highest common Glasswool thickness for residential applications, offering peak thermal performance and significantly contributing to a comfortable indoor environment and lower utility bills.

Choosing the Right Thickness for Your Project

Selecting the optimal Glasswool thickness involves considering several factors:

- Climate Zone: Colder climates or regions with extreme temperature swings will demand a higher R-value, thus requiring a greater insulation thickness.

- Building Codes: Local building codes often specify minimum R-value requirements for different parts of a structure (walls, roofs, floors). Always check these before making a decision.

- Available Space: The depth of your wall cavities, joists, or rafters will dictate how much Glasswool insulation blanket you can fit.

- Budget: While thicker insulation generally costs more upfront, the long-term energy efficiency savings often outweigh the initial expense.

- Desired Performance: Are you prioritizing maximum thermal performance, superior acoustic insulation, or a balance of both?

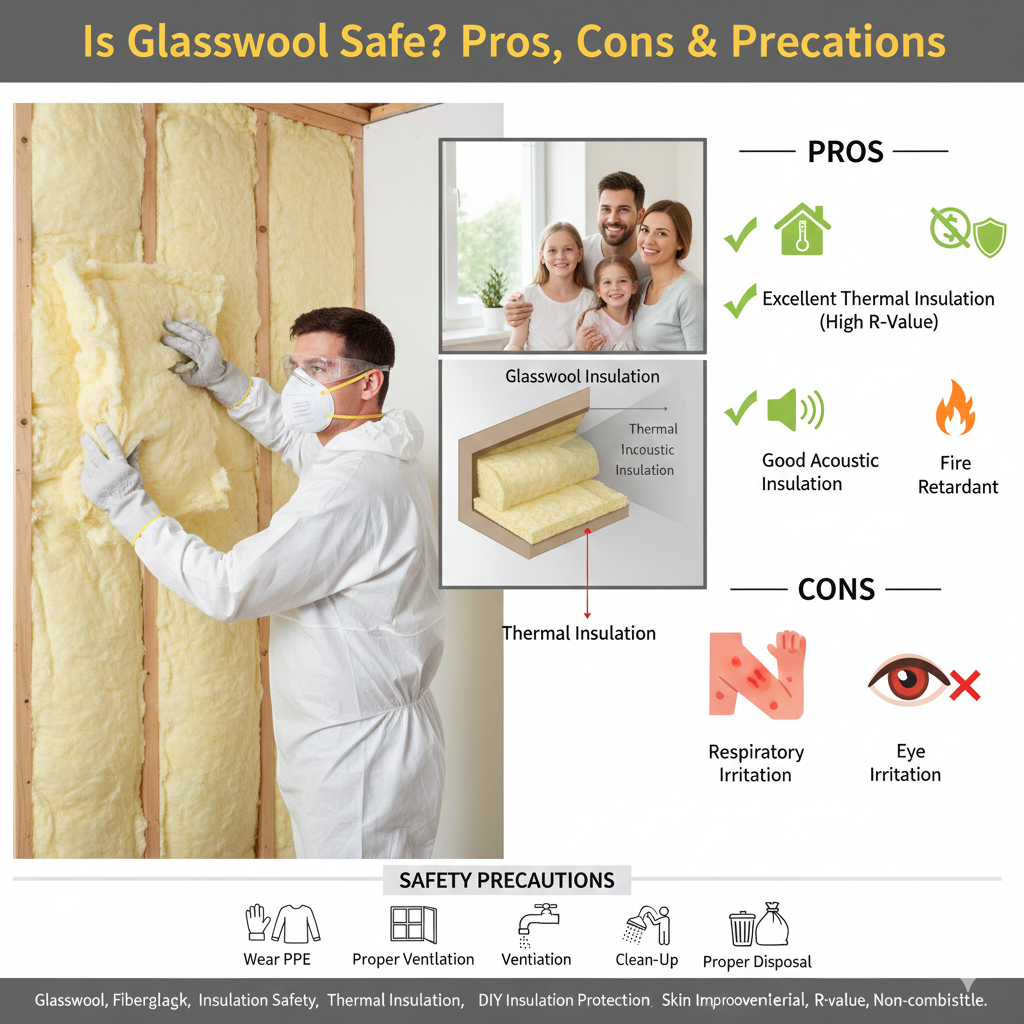

Installation Tips for Different Thicknesses

Regardless of the Glasswool thickness you choose, proper installation tips are crucial for maximizing performance:

- Wear PPE: Always wear gloves, long sleeves, eye protection, and a respirator during DIY insulation.

- Friction Fit: Ensure the insulation is cut slightly wider than the cavity for a snug, friction fit. Avoid compressing it, as this reduces the R-value.

- Continuous Barrier: Minimize gaps and voids to prevent thermal bridging and ensure consistent thermal performance.

- Vapor Barrier: In most applications, especially with wall insulation or roof insulation, a vapor barrier (typically plastic sheeting) is installed on the warm side of the insulation to prevent moisture condensation.

Conclusion: A Strategic Investment in Comfort

Choosing the correct Glasswool thickness is more than just a purchase; it’s a strategic investment in your home’s energy efficiency, comfort, and long-term value. From the basic 25mm Glasswool for acoustic dampening to the robust 100mm Glasswool for maximum thermal performance, each option serves a specific purpose. By understanding the relationship between thickness and R-value, consulting local codes, and following proper installation tips, you can confidently select the ideal insulation blanket to transform your living space into an energy-efficient haven.

FAQ’S

The ideal thickness depends on your purpose. 25mm–50mm is suitable for basic thermal control and noise reduction, while 75mm–100mm is recommended for high-performance insulation in hot climates, metal buildings, HVAC systems, and industrial areas.

Not always. While thicker glasswool provides higher thermal and acoustic performance, it must match the space available and the insulation requirement. For example, walls often use 50mm, while roofs and industrial sheds may require 75mm–100mm.

For acoustic insulation, 50mm to 75mm glasswool offers excellent sound absorption. In recording studios, cinemas, and noise-sensitive areas, 100mm thickness delivers the best performance.

For roofs and metal sheds exposed to extreme heat, 75mm or 100mm glasswool is recommended. It significantly reduces heat transfer, improves energy efficiency, and enhances indoor comfort, especially in hot regions like Pakistan and the Middle East.