Choosing the right insulation material is a critical decision for any construction project. It impacts everything from long-term energy costs to the structural integrity and comfort of the building. Two common choices in the rigid foam insulation market are Jumbolon sheets vs EPS (Expanded Polystyrene) sheets. While both are lightweight, foam-based materials, they are fundamentally different in composition, properties, and overall performance.

This comprehensive guide breaks down the key differences to help you determine which material—Jumbolon or EPS sheet—is the superior option for your specific application.

Understanding the Materials: Jumbolon vs EPS Sheet

The core difference lies in their manufacturing process and material classification.

1. Jumbolon (Extruded Polystyrene – XPS)

Jumbolon is a popular brand name for Extruded Polystyrene (XPS) foam insulation. It is manufactured through a continuous extrusion process that results in a unique structure.

- Structure: Closed-cell, homogenous, and uniform. This tight, non-interconnected cell structure is key to its superior properties.

- Key Advantage: The closed-cell structure makes it an extremely effective moisture-resistant foam and accounts for its high compressive strength.

2. EPS Sheet (Expanded Polystyrene)

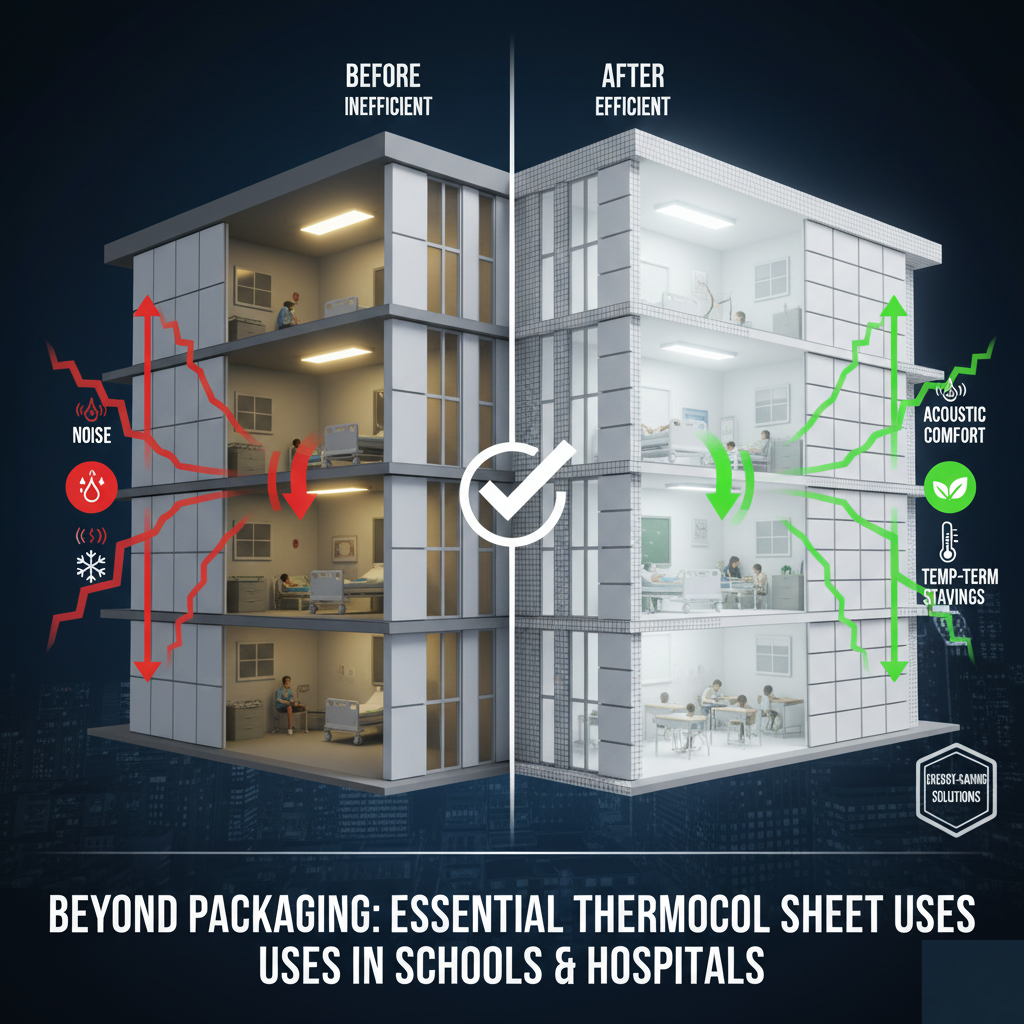

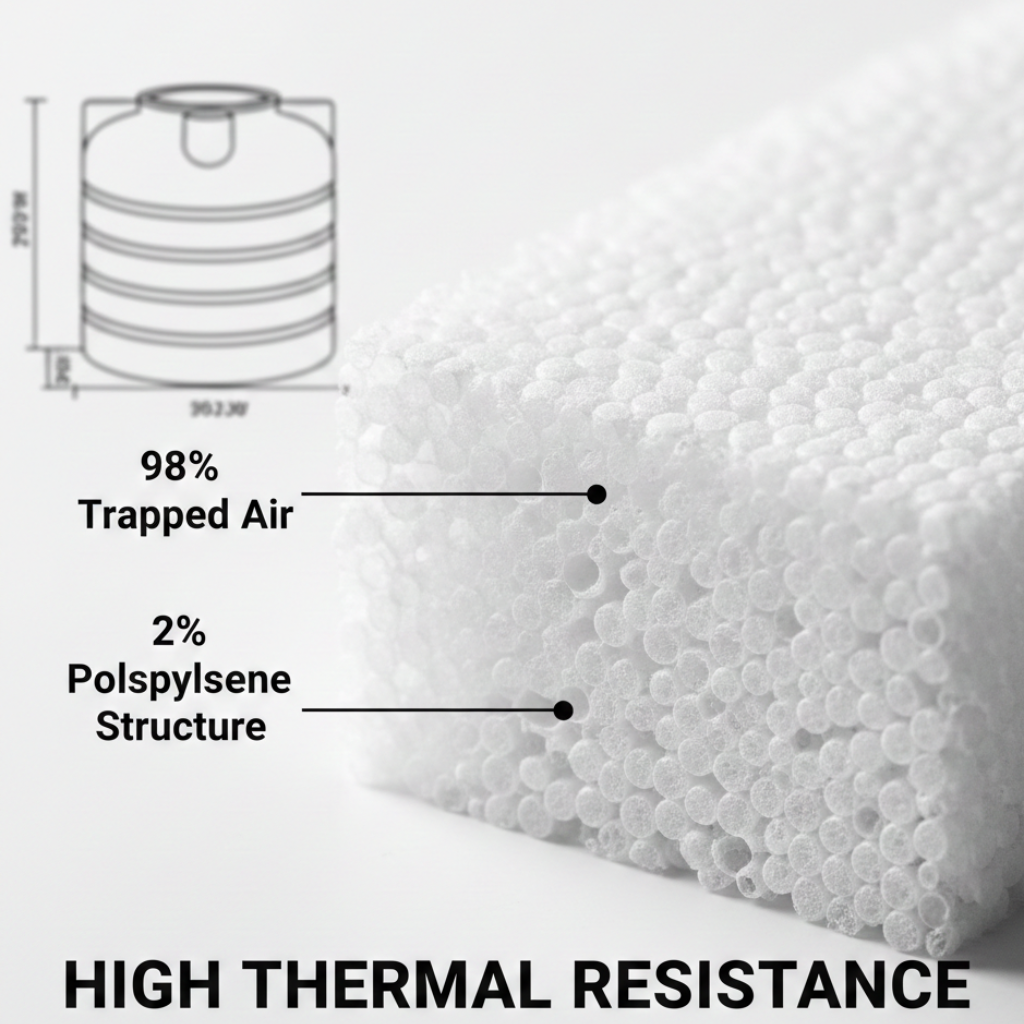

Expanded Polystyrene (EPS) sheets, sometimes colloquially referred to as Thermopore or Thermocol, are made by expanding polystyrene beads with steam, fusing them into a solid block, and then cutting the block into sheets.

Key Advantage: It is highly cost-effective and lightweight.

Structure: Closed-cell, but the cells are not completely interconnected; there are tiny voids between the fused beads.

Performance Comparison: Jumbolon vs. EPS Sheet

The performance of an insulating material is measured by several key criteria, including thermal efficiency, resistance to moisture, and long-term durability.

1. Thermal Insulation (R-Value)

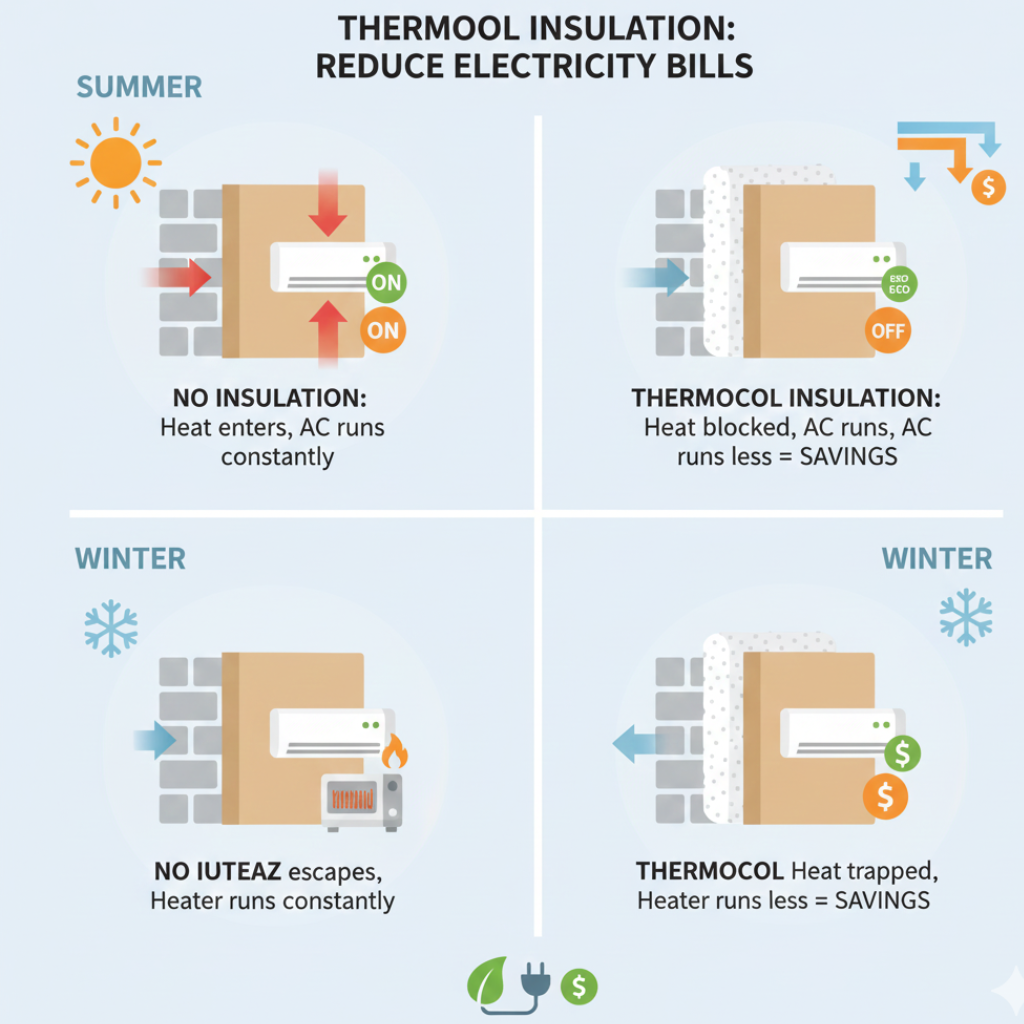

The R-value measures a material’s resistance to heat flow. A higher R-value indicates better thermal resistance and insulating capability.

| Feature | Jumbolon (XPS) | EPS Sheet (Expanded Polystyrene) | Verdict |

| R-Value per Inch | Generally $\approx 5$ | Generally $\approx 3.6 – 4.2$ | Jumbolon (XPS) offers a significantly higher R-value per inch, providing superior thermal performance in thinner applications. |

| Long-Term Performance | Maintains R-value exceptionally well over time. | Can see a slight drop in R-value if exposed to moisture over the long term. | Jumbolon (XPS) maintains efficiency better. |

2. Moisture Resistance and Water Absorption

Water absorption is critical, as a wet insulator loses its R-value rapidly.

- Jumbolon (XPS): Due to its fine, uniform closed-cell structure, it is highly hydrophobic. It has very low water absorption (often $< 0.3\%$ by volume, even when submerged) and is an excellent water-resistant insulation choice, making it ideal for below-grade applications and areas prone to dampness.

- EPS Sheet: While largely closed-cell, the spaces between the fused beads can allow water vapor to permeate and, in prolonged exposure to moisture, it can absorb more water (up to $2-3\%$ by volume).

Verdict: Jumbolon (XPS) is the clear winner for moisture resistance, ensuring stable performance in humid or wet environments.

3. Compressive Strength

Compressive strength is the material’s ability to withstand loads without deforming or failing.

- Jumbolon (XPS): Features a high compressive strength (often $250 – 350$ KPa or more). Its dense, uniform structure makes it ideal for bearing heavy loads.

- EPS Sheet: Compressive strength is good but varies significantly with the density grade. It typically performs well but is generally less robust than XPS at comparable densities.

Verdict: Jumbolon (XPS) is better suited for applications under high load or pressure, such as floor insulation and roof insulation.

Common Applications of Jumbolon Vs EPS Sheet

The best choice often depends on the specific job.

| Application | Jumbolon (XPS) Recommendation | EPS Sheet Recommendation |

| Below-Grade Insulation (Foundations, Slabs) | Strongly Recommended (Due to high moisture resistance and compressive strength). | Not ideal for long-term below-grade use where persistent moisture is a factor. |

| Wall Insulation (Cavity or Exterior) | Excellent choice (High R-value, durability). | Good choice (Cost-effective and lightweight for above-grade walls). |

| Roof Insulation (Flat or Pitched) | Recommended (Withstands environmental stress and traffic loads better). | Suitable for light-load roof systems where cost is the primary factor. |

| General Packaging/Void Fill | Overkill, generally too expensive. | Highly Recommended (Most cost-effective foam for non-structural, protective use). |

Cost-Effectiveness and Durability

While Jumbolon provides better performance, the final decision often comes down to budget and long-term value.

- Initial Cost: The Expanded Polystyrene (EPS sheet) typically has a lower insulation material cost per square foot than Jumbolon (XPS). It is the more budget-friendly option upfront.

- Long-Term Value: Jumbolon’s long-lasting insulation properties—its superior moisture resistance and higher R-value retention—mean it can offer better lifetime value and greater energy efficiency over the decades, leading to lower utility bills. Its durability also reduces the risk of material replacement.

Conclusion: Which Is Better Jumbolon Vs EPS Sheet?

There is no single “better” material; there is only the right material for the job.

- Choose Jumbolon (XPS) when:

- You need the highest possible thermal resistance in a limited thickness.

- The application involves persistent moisture, such as a basement, foundation, or water tank insulation.

- The material will be subject to heavy loads, such as in floor insulation or a trafficable roof.

- Choose EPS Sheet when:

- The budget is the primary constraint.

- The application is for above-grade walls where it will be protected from direct water exposure.

- The material is for lightweight use like packaging or a quick, non-structural heat proofing solution.

In the final analysis, for applications requiring long-lasting insulation and maximum thermal performance under challenging conditions, the superior compressive strength and moisture-resistant foam properties of Jumbolon (XPS) make it the clear technical winner, justifying its higher insulation material cost.

FAQ’S

The main difference lies in how they are manufactured. Jumbolon (XPS) is made through an extrusion process, resulting in a closed-cell, highly uniform structure with no internal voids. This structure gives it superior moisture resistance and high compressive strength. EPS sheets are made by expanding and fusing beads, resulting in a closed-cell structure but with tiny air voids between the fused beads, which allows for slightly higher water vapor permeability and absorption over time.

Yes, Jumbolon (XPS) is highly recommended for basement, foundation, and other below-grade insulation applications. This is because these areas are prone to constant moisture exposure. Jumbolon’s extremely low water absorption and high moisture-resistant foam properties ensure its R-value remains stable and its performance is not compromised by groundwater or damp soil, unlike EPS, which can absorb more water over the long term.

Jumbolon (XPS) generally offers better long-term performance and R-value retention. While both materials have high initial R-values, Jumbolon’s robust, closed-cell structure is inherently resistant to moisture ingress. Since water infiltration is the primary cause of R-value degradation in foam insulation, the superior water resistance of Jumbolon ensures it maintains its specified thermal resistance over the lifespan of the building more reliably than standard EPS sheets.

An EPS sheet is the most cost-effective foam option when the application is above-grade and not exposed to constant moisture or high structural loads. It is a great budget-friendly choice for non-structural applications like general wall insulation, temporary heat proofing, or protective packaging where its slightly lower R-value per inch and higher permeability are acceptable trade-offs for a lower insulation material cost.