Introduction: What Makes XPS Sheet Insulation a Construction Staple?

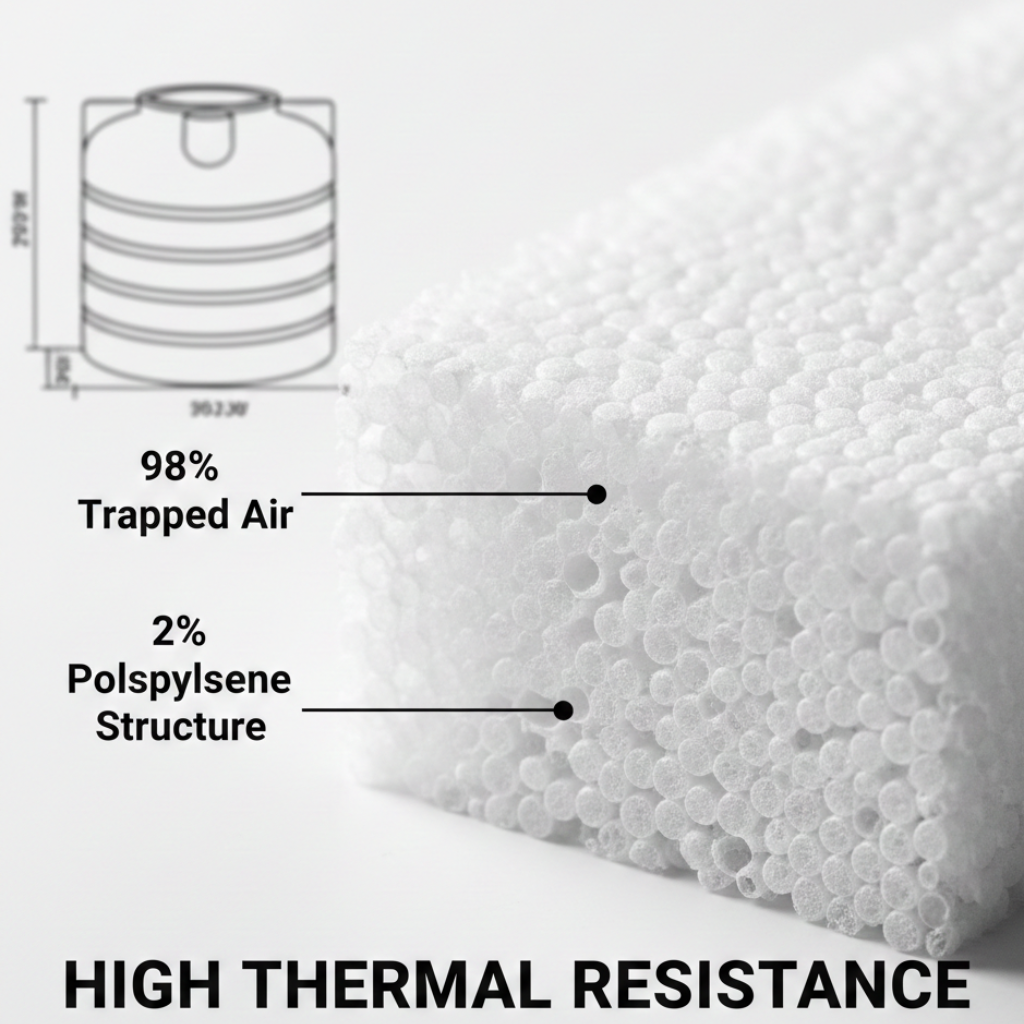

In the world of building materials, few products achieve. The combination of durability and thermal performance offered by XPS Sheet Insulation, or Extruded Polystyrene Foam. Easily recognized by its distinct pink, blue, or green color. Expanded Polystyrene (EPS), due to a specialized manufacturing process called extrusion.

This process results in a material with a unique closed-cell structure that is uniform, dense, and remarkably robust. This density is the fundamental reason why XPS is the material of choice for the most challenging insulation applications in modern construction. Its superior qualities ensure buildings maintain exceptional energy efficiency and structural integrity over the decades.

The Critical Advantage of Moisture Resistance

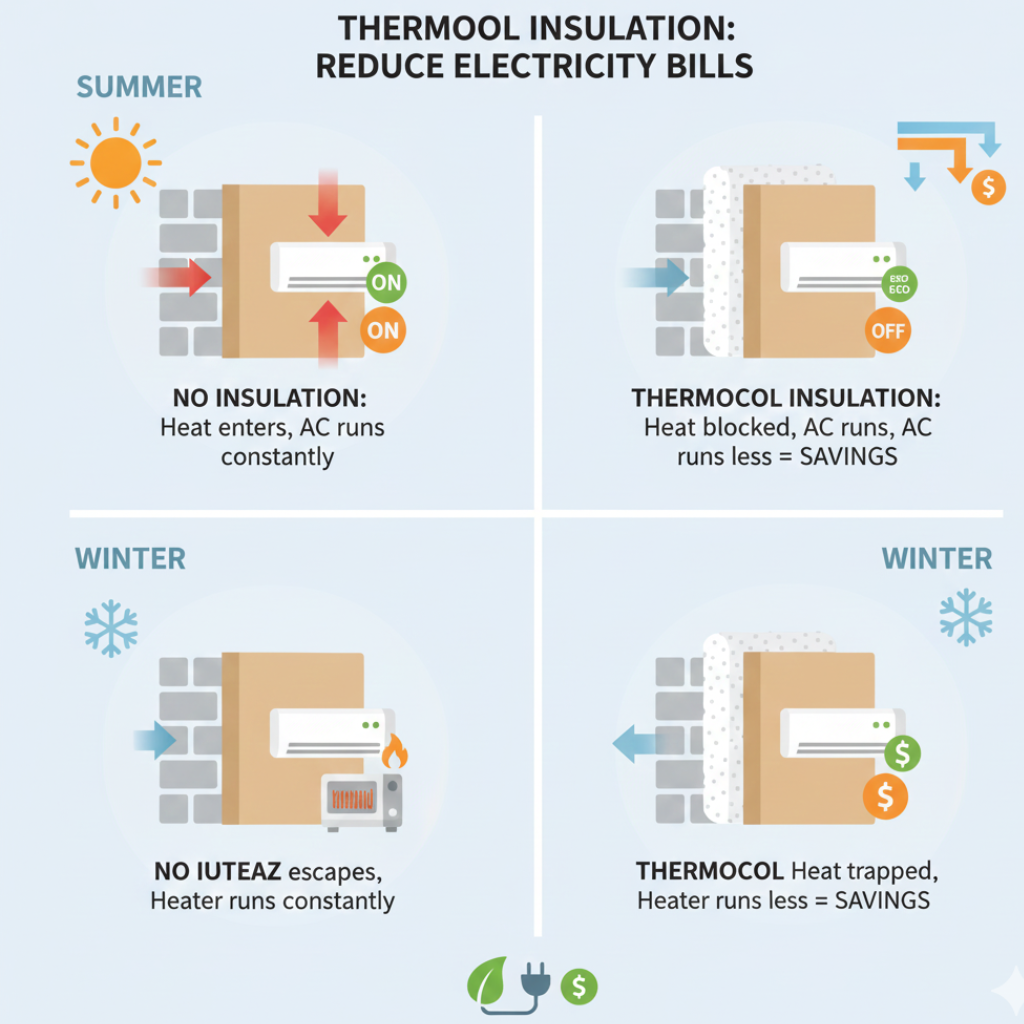

The single greatest threat to insulation performance is water. When traditional fibrous or open-cell insulation materials absorb moisture, their thermal resistance plummets, leading to energy waste, mold growth, and structural issues. This is where the closed-cell structure of XPS offers a significant, non-negotiable advantage.

The non-interconnected foam cells of Extruded Polystyrene Foam physically repel water, resulting in extremely low water absorption. This superior moisture resistance ensures that the material maintains its insulating power even when directly exposed to damp or wet conditions, such as continuous contact with soil or heavy rain. This durability is the primary factor driving its selection for submerged or high-humidity environments.

High Compressive Strength and Load-Bearing Applications

In many areas of a building envelope, insulation is required to bear significant weight without deforming. Standard foam insulations may fail under pressure, but XPS is specifically engineered to resist crushing, featuring a consistently high compressive strength.

The tight cellular structure gives XPS Sheet Insulation a remarkable load-bearing capacity. This property makes it indispensable for applications where heavy static or dynamic loads are present:

- Under Slabs: Insulating concrete floors and rafts where the material must support the entire weight of the slab, finished floor, and live loads.

- Parking Decks: Used in commercial projects beneath pavers or asphalt where vehicle traffic demands maximum structural stability.

This resistance to pressure guarantees the long-term thermal performance of the assembly, preventing costly structural movement and cold spots that arise from compromised insulation.

Applications Where XPS Excels – Below-Grade and Inverted Systems

The unique properties of Extruded Polystyrene Foam make it the undisputed champion for specific, demanding installation types.

Below-Grade Applications and Foundation Walls

Insulating the exterior of foundation walls and basements is known as below-grade applications. This environment is challenging because the insulation is constantly exposed to soil moisture, hydrostatic pressure, and seasonal freezing/thawing cycles. The moisture resistance and high compressive strength of XPS are perfectly suited here. Installing XPS Sheet Insulation around the foundation helps prevent thermal bridging and keeps the basement space warm and dry, significantly improving the home’s overall energy efficiency. It functions as essential perimeter insulation, protecting the concrete from extreme temperature swings.

Inverted Roof Systems

A revolutionary application where XPS is mandatory is the inverted roof systems (or protected membrane roofs). In this design, the rigid foam boards are placed above the waterproofing membrane, rather than below it. This protects the membrane from extreme temperature fluctuations and damaging UV rays, thereby extending the waterproofing system’s life. The XPS boards must have enough strength and moisture resistance to withstand standing water, foot traffic, and the weight of ballast (gravel or paving stones) without absorbing water or deforming.

Performance Metrics and Long-Term Value

When evaluating any insulation, its thermal resistance and stability over time are key indicators of its value.

R-Value Stability

XPS insulation typically boasts an initial R-value of around R-5 per inch of thickness. However, which is generally higher than standard EPS. However, one key advantage often cited is its R-value stability. While some foam insulation boards may experience a slight long-term reduction in R-value due to the diffusion of the blowing agent. The dense, closed-cell structure of XPS is designed to minimize this effect, providing reliable long-term thermal performance. This predictability is crucial for architects and builders calculating lifetime energy efficiency savings.

The Cost-Benefit of Durability

While XPS Sheet Insulation may have a higher initial material cost compared to standard EPS or fiberglass. Its superior durability, moisture resistance, and minimal need for replacement in tough environments like below-grade applications translate to lower long-term thermal performance costs. By effectively insulating foundation walls and high-load areas. XPS ensures the structural health and thermal integrity of the building for its entire lifespan. The investment in robust perimeter insulation and high load-bearing capacity foam dramatically reduces future maintenance expenses.

Conclusion: The Right Tool for the Toughest Jobs

XPS Sheet Insulation is a premium, high-performance material indispensable for specialized construction challenges. Its unbeatable moisture resistance and exceptional high compressive strength. Moreover, make it the logical choice for inverted roof systems and all below-grade applications, including insulating foundation walls. By utilizing its superior R-value stability and robust load-bearing capacity for crucial perimeter insulation. Furthermore, builders achieve unparalleled energy efficiency and ensure the long-term thermal performance of the entire structure. For demanding environments, Extruded Polystyrene Foam is the reliable, durable solution.

FAQ’S

While XPS is known for its excellent initial thermal performance (around R-5 per inch), it does experience a gradual reduction in R-value over time, a phenomenon known as thermal drift. This occurs because the initial captive blowing agent within the material’s closed-cell structure slowly escapes and is replaced by air. However, the dense structure of Extruded Polystyrene Foam causes this drift to happen at a slower rate compared to some other foam boards. Manufacturers are required to report the Long-Term Thermal Performance (LTTR), which represents the stable R-value expected over the product’s lifespan, ensuring the building’s calculated energy efficiency is met.

Yes, XPS is the preferred rigid foam for virtually all below-grade applications, including foundations and areas with fluctuating water tables. Its manufacturing process creates a closed-cell structure that provides superior moisture resistance, preventing water from being wicked up or absorbed into the insulation core. This ensures that the material’s insulating capacity is maintained even when the perimeter insulation around the foundation walls is submerged or subjected to constant dampness. Its high compressive strength further allows it to resist pressure from soil and water without deforming.

The high compressive strength is crucial when XPS is used beneath concrete slabs, floors, or in inverted roof systems. This exceptional load-bearing capacity means the Extruded Polystyrene Foam can withstand the immense weight of the concrete and subsequent live loads (people, vehicles, equipment) without crushing or permanently deflecting. Maintaining its thickness is vital, as any compression would compromise the entire assembly and negatively impact the long-term thermal performance of the slab insulation, leading to cold spots and thermal bridging.

Generally, no. While the distinct coloration (often pink, blue, or green) is the primary way to visually identify XPS Sheet Insulation from white EPS, the color typically only indicates the manufacturer or brand (e.g., pink for one major brand, blue for another). The core performance properties—like the R-value stability, closed-cell structure, and high compressive strength—are governed by the product’s type (e.g., Type IV, Type VI) and thickness, which should be verified on the product label, not assumed based on color.