Glasswool is a phenomenal material for both thermal insulation and soundproofing, but not all glasswool is created equal. Its effectiveness, particularly for acoustic treatment, largely depends on its density. Choosing the right density of glasswool insulation is crucial for achieving optimal results, whether you’re tackling noise reduction in a home studio or an industrial setting. This guide will help you navigate the options and make an informed decision for your specific application.

Understanding Density: What it Means for Acoustic Performance

Density in glasswool panels refers to the mass per unit volume, typically measured in kilograms per cubic meter (kg/m³). It directly impacts how effectively the material can absorb and dissipate sound energy.

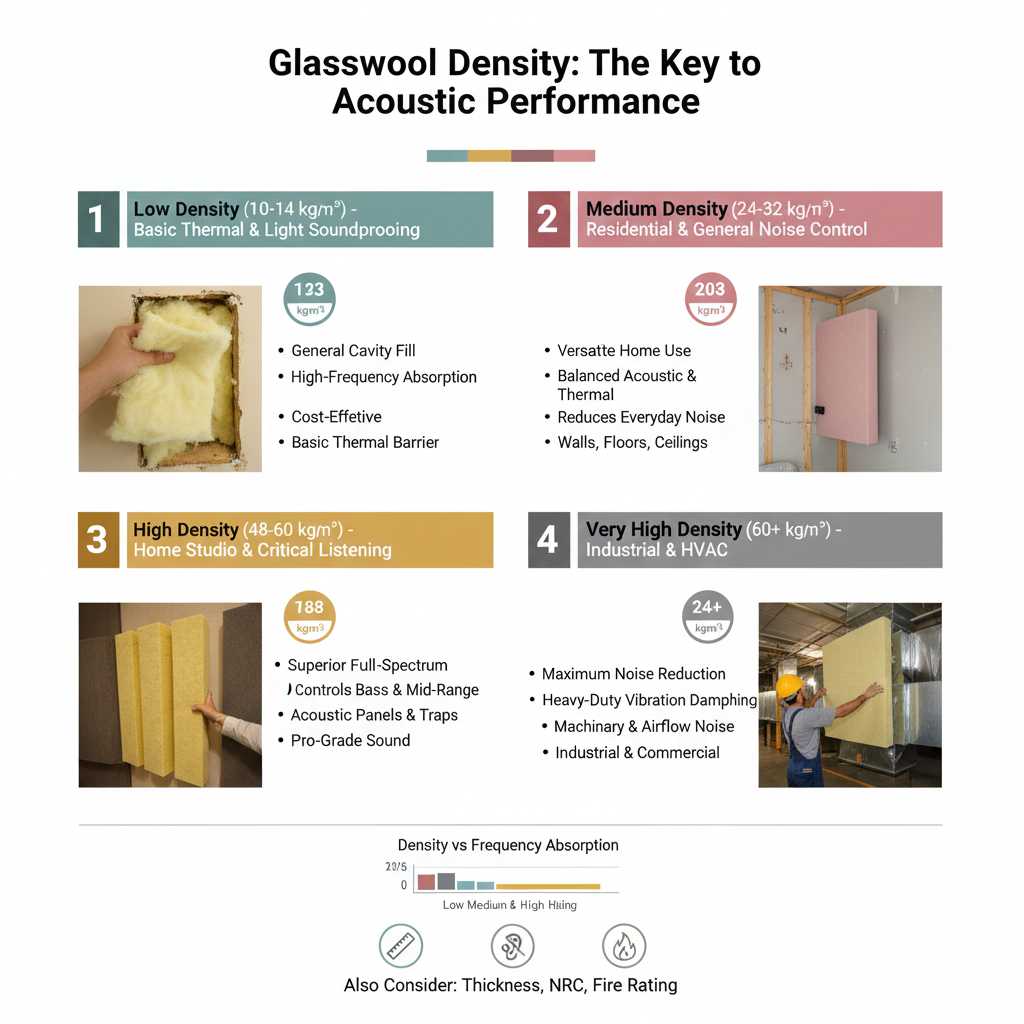

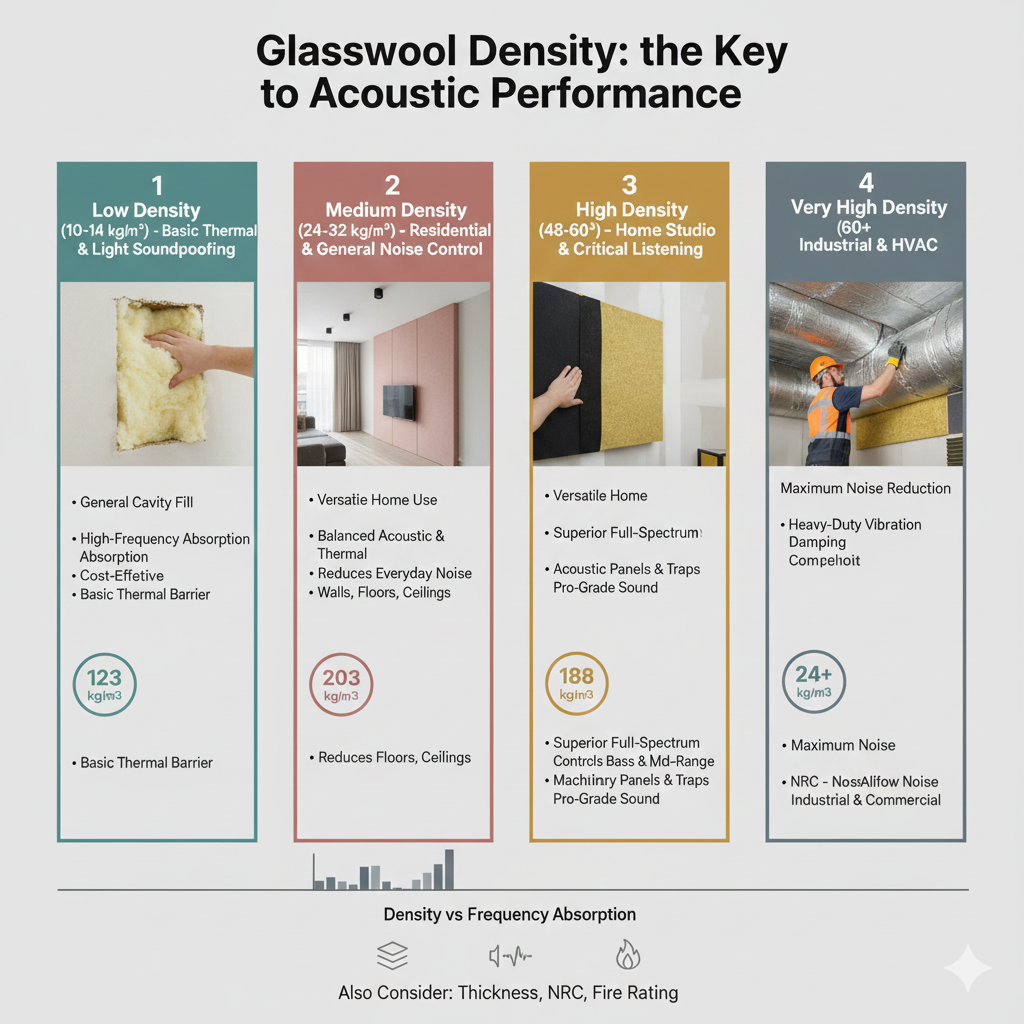

- Low Density (e.g., 10-14 kg/m³): Lighter, less fibrous. Excellent for basic thermal insulation and offers some sound absorption, primarily for higher frequencies. It’s often more cost-effective for general cavity filling.

- Medium Density (e.g., 24-32 kg/m³): A versatile option, providing a good balance of thermal insulation and improved acoustic performance. This range is often a go-to for residential soundproofing material.

- High Density (e.g., 48 kg/m³ and above): Denser, more rigid. Offers superior noise reduction across a broader frequency spectrum, including lower frequencies. Ideal for demanding acoustic treatment scenarios.

The denser the glasswool insulation, the more internal friction and resistance it offers to sound waves, leading to better vibration dampening and overall sound absorption.

Matching Density to Application: A Practical Guide

The “sweet spot” for density varies significantly based on where and how you plan to use your glasswool sheets.

1. Residential Spaces (General Soundproofing & Thermal Insulation)

For standard walls, ceilings, and floors in homes where both thermal insulation and moderate noise reduction are desired, medium density glasswool (24-32 kg/m³) is often the most practical choice. It offers sufficient sound dampening for everyday noise and is cost-effective. For a bedroom or living area seeking better noise control, opting for the higher end of this range or slightly above is beneficial.

2. Dedicated Home Studio & Critical Listening Environments

When building a home studio or a high-fidelity listening room, acoustic performance is paramount. Here, high density glasswool (48-60 kg/m³) is highly recommended. It excels at absorbing a wider range of frequencies, particularly crucial for controlling bass and mid-range frequencies, which are common in music production. These acoustic panels provide superior sound absorption for a more accurate and controlled sound environment.

3. Commercial and Office Spaces (Partitions & Ceilings)

In an office space or commercial building, the goal is often to enhance speech privacy and reduce general ambient noise. Medium to high density glasswool (32-48 kg/m³) is suitable for partition walls and suspended ceiling panels. This helps create a quieter work environment, improving focus and communication. The specific acoustic performance target will guide the precise density selection.

4. Industrial & HVAC Systems (Heavy Duty Noise Control)

For industrial applications or damping noise from HVAC ductwork, where intense noise reduction is critical, very high density glasswool (60 kg/m³ and above) or even specialized rigid glasswool boards are preferred. These robust materials can withstand harsh conditions while providing maximum sound dampening and vibration dampening against machinery and airflow noise.

Beyond Density: Other Factors to Consider

While density is a primary factor, keep these additional points in mind when selecting your soundproofing material:

- Thickness: Thicker insulation generally offers better acoustic performance, especially for lower frequencies, regardless of density.

- Installation: Ensure the glasswool sheets fit snugly without compression. Proper installing is key to effectiveness.

- N.R.C. (Noise Reduction Coefficient): Look for the NRC rating, which indicates the material’s ability to absorb sound. A higher NRC means better sound absorption.

- Fire Rating: For certain applications, check the fire resistance rating of the glasswool insulation.

By carefully considering the right density in conjunction with your specific application and these additional factors, you can confidently choose the optimal glasswool solution to create your desired quiet and acoustically controlled environment.

FAQ’S

Density directly affects sound absorption, thermal performance, and structural stability. Higher-density glasswool provides better acoustic control and stronger insulation for industrial or commercial use, while lower-density options are sufficient for basic thermal insulation in homes.

For effective acoustic treatment, glasswool with a density of 48 kg/m³ to 96 kg/m³ is recommended. Higher densities provide better sound absorption, especially in studios, cinemas, offices, or noisy commercial areas.

For residential and commercial thermal insulation, glasswool with a density of 16 kg/m³ to 32 kg/m³ is typically used. It provides excellent heat resistance, energy savings, and overall comfort for roofs, ceilings, and walls.

Industrial and HVAC systems require high-density glasswool (48–64 kg/m³ or more) due to higher temperature exposure, vibration, and strict performance requirements. High density enhances durability, fire resistance, and thermal stability under tough conditions.

Leave a Reply