In Pakistan’s extreme climate, especially during long summers, homeowners and commercial property owners often search for solutions to control indoor temperatures. Two commonly used terms—heat proofing and thermal insulation—are frequently confused or used interchangeably. While both aim to improve comfort and energy efficiency, their purpose, performance, and applications differ significantly.

This guide clearly explains the difference between insulation for heat proofing vs insulation, helping you make the right decision based on climate, building type, and budget.

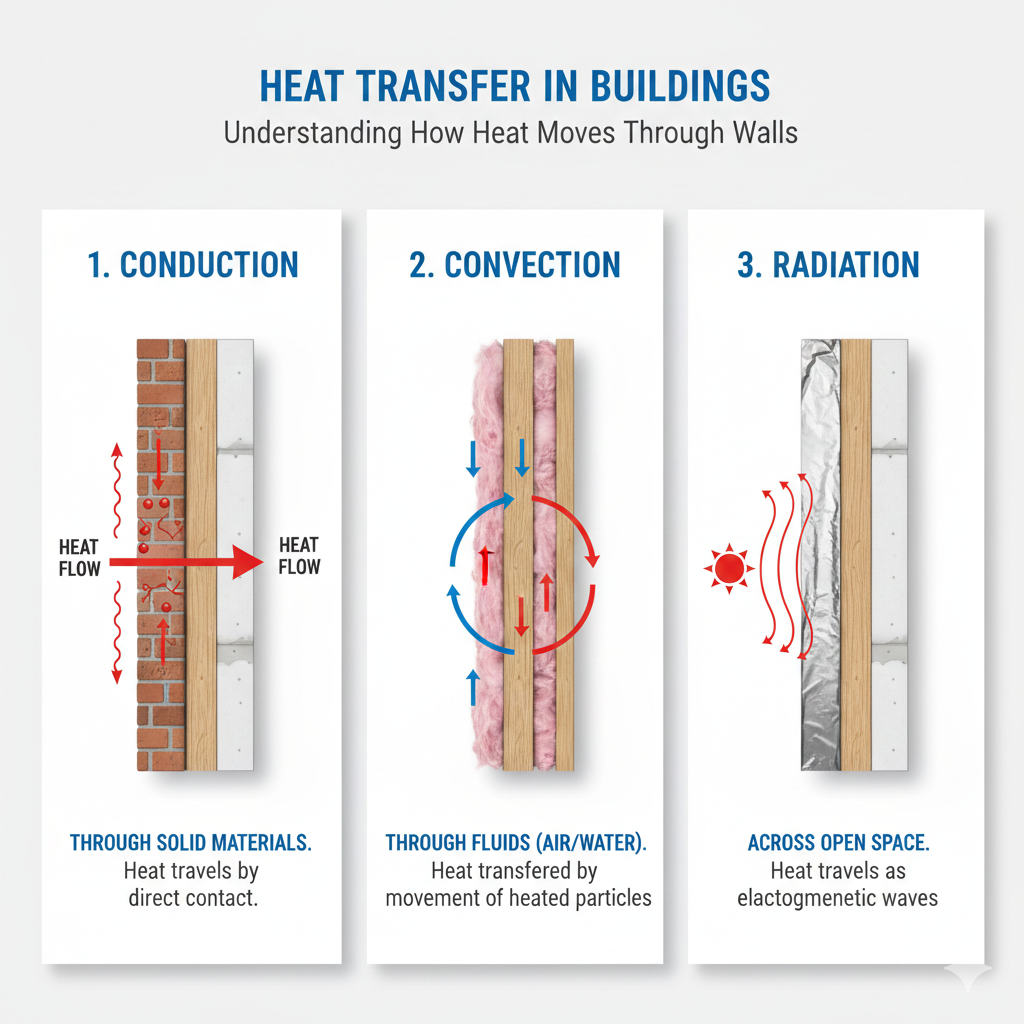

Understanding Heat Transfer in Buildings

Before comparing solutions, it’s important to understand how heat behaves.

Heat enters and exits buildings through:

- Roofs exposed to direct sunlight

- External walls

- Poorly insulated ceilings

- Metal structures and water tanks

The movement of heat occurs due to thermal conductivity, which measures how easily heat passes through a material. Materials with low thermal conductivity are more effective at controlling indoor temperatures.

What Is Heat Proofing?

Heat proofing focuses on blocking external heat, especially radiant heat from the sun. It is commonly applied to roofs, water tanks, and top floors of buildings.

Key Characteristics of Heat Proofing

- Reflects solar radiation

- Reduces surface temperature

- Works best in hot climates

- Mainly protects against external heat gain

In Pakistan, heat proofing is widely used on rooftops to reduce indoor temperatures during peak summer months.

Common Heat Proofing Applications

- Roof slabs

- Metal sheds

- Water tanks

- Warehouses

Due to rising demand, heat proofing services in Pakistan have become a popular seasonal solution for residential and commercial buildings.

What Is Thermal Insulation?

Thermal insulation is designed to control heat flow in both directions—keeping heat out in summer and retaining warmth in winter. It works by resisting heat movement through walls, ceilings, and floors.

Key Characteristics of Thermal Insulation

- Reduces heat loss and heat gain

- Improves year-round comfort

- Enhances energy efficiency

- Suitable for long-term building performance

Thermal insulation plays a major role in managing heat retention, especially during colder months.

Insulation for Heat Proofing vs Insulation – Core Differences

| Feature | Heat Proofing | Thermal Insulation |

|---|---|---|

| Primary function | Reflects external heat | Controls heat flow |

| Seasonal benefit | Summer-focused | Year-round |

| Application areas | Roofs, tanks, sheds | Walls, roofs, ceilings |

| Energy efficiency | Moderate | High |

| Long-term performance | Medium | Excellent |

Role of Insulation for Thermal Conductivity

Insulation materials are selected based on their thermal conductivity value. Lower conductivity means better resistance to heat transfer.

- Heat proofing materials mainly reflect radiant heat

- Thermal insulation materials slow down heat movement through structure

This difference is why insulation for thermal conductivity plays a more critical role in permanent buildings.

Heat Proofing Price vs Insulation Cost

Heat Proofing Price

The heat proofing price in Pakistan is generally lower because it involves surface-level treatment. Costs vary depending on:

- Roof size

- Type of reflective coating or sheet

- Labor charges

Thermal Insulation Cost

Thermal insulation usually requires higher upfront investment but delivers long-term energy savings by reducing cooling and heating expenses.

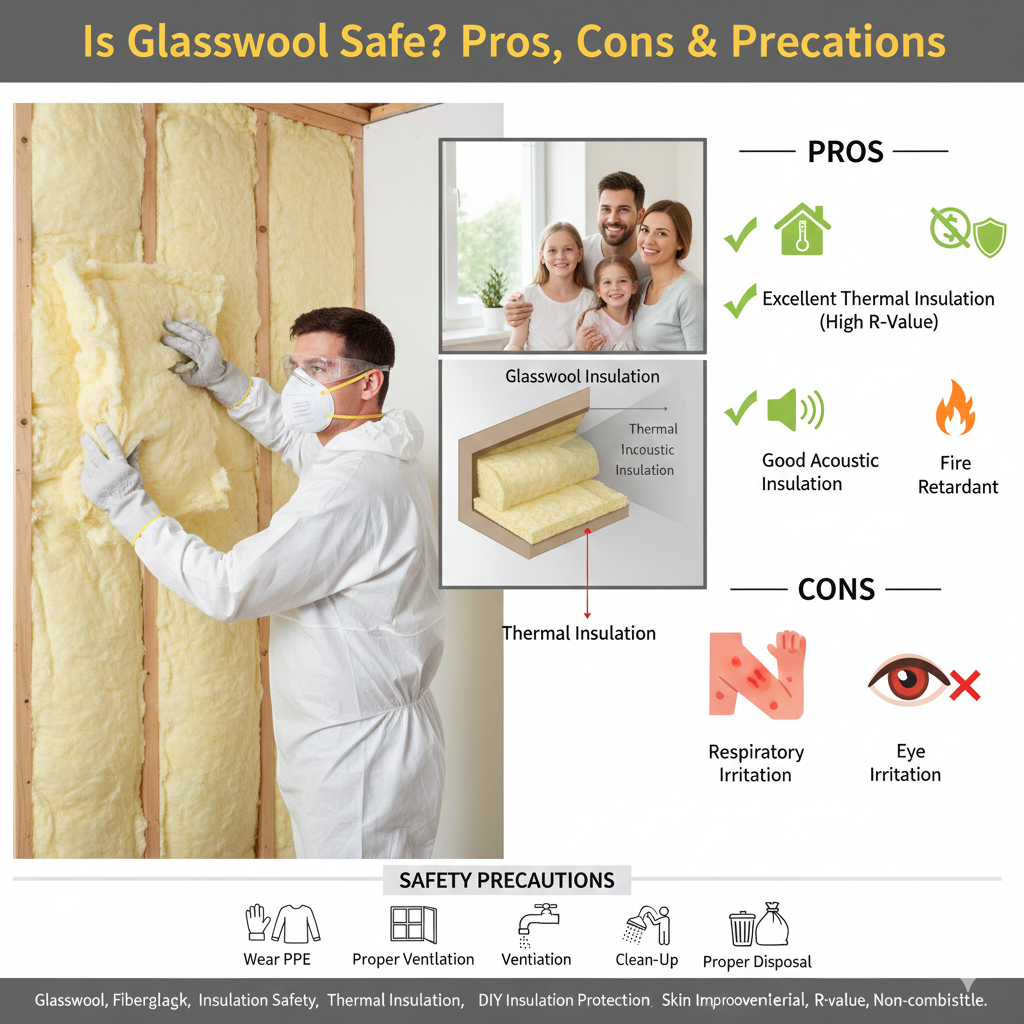

Acoustic Insulation – An Added Advantage

One major benefit of insulation materials is acoustic insulation. Unlike heat proofing, thermal insulation materials often help reduce noise transmission.

This makes insulation ideal for:

- Homes near busy roads

- Commercial buildings

- Industrial units

- Hospitals and schools

Heat proofing does not significantly contribute to sound control.

Which One Should You Choose?

Choose Heat Proofing If:

- You live in an extremely hot region

- Your roof receives direct sunlight

- You want a short-term temperature reduction

- Budget is limited

Choose Thermal Insulation If:

- You want long-term energy efficiency

- Your building needs temperature stability

- You want both heat control and acoustic insulation

- You are constructing or renovating a building

Many modern projects now combine both systems for maximum performance.

Heat Proofing Services in Pakistan – Growing Demand

With rising temperatures, heat proofing services in Pakistan are increasingly used in:

- Karachi

- Lahore

- Multan

- Faisalabad

- Islamabad

However, experts recommend combining heat proofing with thermal insulation for optimal results.

Final Thoughts

Understanding the difference between insulation for heat proofing vs insulation helps you invest wisely. Heat proofing provides immediate relief from sunlight-driven heat, while thermal insulation delivers long-term comfort, energy savings, and noise reduction.

The best solution often depends on building structure, climate conditions, and performance expectations.

FAQ’S

Heat proofing mainly reflects external heat and reduces surface temperature, while thermal insulation controls heat flow by reducing thermal conductivity, helping with both cooling and heat retention throughout the year.

Thermal insulation is better for long-term comfort because it works in both summer and winter. Heat proofing services in Pakistan are useful for roofs exposed to extreme sunlight, but insulation provides broader performance benefits.

Yes, thermal insulation materials often provide acoustic insulation by absorbing sound vibrations. Heat proofing systems generally do not offer sound reduction benefits.

Heat proofing price depends on roof area, material type, application method, and labor costs. Thermal insulation usually costs more initially but delivers better energy efficiency over time.