Rising temperatures and increasing energy costs have made thermal insulation an essential part of modern construction. Among lightweight and cost-effective solutions, Bubble Aluminium Foil Insulation has gained strong popularity for roofs, walls, and windows. This guide explains how it works, where it performs best, and how to evaluate quality and pricing before making a purchase.

What Is Bubble Aluminium Foil Insulation?

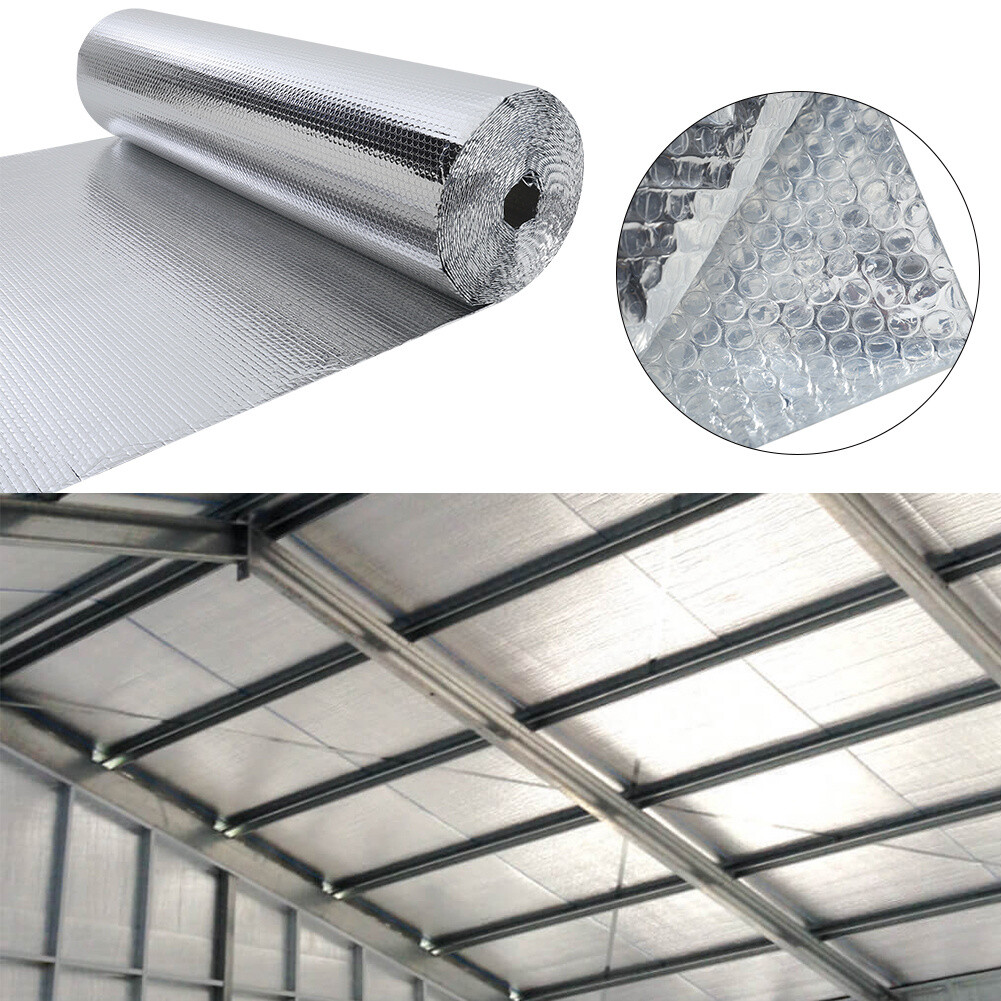

Bubble aluminium foil insulation is a How Bubble Aluminium Foil Insulation Works

The performance of bubble foil insulation is based on two mechanisms:

- Radiant heat reflection through aluminium foil surfaces

- Air entrapment inside bubbles that reduces conductive heat flow

This dual-action approach helps control indoor temperatures during extreme weather, especially in hot climates.multi-layer insulation material made by combining air-filled bubble layers with reflective aluminium foil surfaces. The trapped air bubbles slow down heat transfer, while the foil reflects radiant heat away from the building.

This structure allows thermal insulation to work efficiently without adding heavy load to roofs or walls, making it suitable for residential, commercial, and industrial use.

Key Benefits of Bubble Aluminium Foil Insulation

1. Effective Thermal Control

Bubble foil significantly reduces heat gain in summer and heat loss in cooler months, improving indoor comfort throughout the year.

2. Lightweight & Easy Installation

Unlike rigid insulation boards, bubble insulation is flexible and easy to cut, fold, and install on roofs, walls, and ceilings.

3. Moisture & Condensation Resistance

Aluminium foil surfaces act as a moisture barrier, reducing condensation risks in humid environments.

4. Space-Saving Insulation Solution

Because of its thin profile, bubble foil is ideal where space limitations make thick insulation impractical.

Best Bubble Aluminium Foil Insulation Applications

Roof Heat Protection

Bubble foil is commonly installed under metal and concrete roofs to block radiant heat before it enters living spaces.

Walls & Ceilings

It works well as a supplementary insulation layer behind wall cladding or ceiling panels.

Bubble Wrap Insulation for Windows

Bubble wrap insulation for windows is an effective way to reduce heat transfer through glass surfaces, especially in sun-exposed areas.

Warehouses & Industrial Sheds

Large roof areas benefit from reflective insulation that reduces internal heat buildup.

Bubble Aluminium Foil Insulation Comparison Table

| Insulation Type | Thickness Profile | Heat Control Method | Common Usage |

|---|---|---|---|

| Bubble Aluminium Foil Insulation | Very Thin | Radiant heat reflection + air gap | Roofs, walls, windows |

| Glasswool Insulation | Medium | Air trapping (conductive resistance) | Roofs, ceilings |

| Rockwool Insulation | Thick | High-density thermal resistance | Walls, fire-rated areas |

| EPS Sheets | Medium | Conductive heat reduction | Walls, roofs |

| XPS Boards | Medium to Thick | High thermal resistance | Floors, roofs |

Note: Bubble foil performs best when installed with proper air spacing and sealed joints.

How to Choose the Best Bubble Aluminium Foil Insulation

When selecting the best Bubble Aluminium Foil Insulation, consider:

- Number of bubble layers

- Quality and thickness of aluminium foil

- Tear resistance and flexibility

- Installation environment (roof, wall, window, or ducting)

Higher-quality foil and consistent bubble structure generally provide better thermal performance.

Bubble Aluminium Foil Insulation vs Traditional Insulation

Compared to bulky insulation materials, bubble foil offers:

- Faster installation

- Lower structural load

- High radiant heat reflection

- Minimal thickness requirements

However, it is often used alongside other materials for maximum insulation efficiency.

Reflective Bubble Aluminium Foil Insulation Price Factors

The Reflective Bubble Aluminium Foil Insulation price depends on several factors:

- Single or double bubble layers

- Foil thickness and reflectivity

- Roll width and length

- Project quantity

For buyers comparing thermal insulation price, bubble foil often sits between basic reflective sheets and high-density insulation boards.

In local markets, thermal insulation price Pakistan varies by supplier, city, and specification, making it important to compare material quality rather than price alone.

Installation Tips for Better Performance

To maximize insulation efficiency:

- Install foil with an air gap where possible

- Seal joints properly using reflective tape

- Avoid compressing the bubble layer

- Ensure foil faces the heat source

Correct installation plays a major role in achieving long-term results.

Environmental & Energy Efficiency Benefits

Bubble aluminium foil insulation contributes to energy efficiency by reducing cooling demand, which helps lower electricity consumption and carbon footprint over time. Its durability also minimizes replacement frequency.

Conclusion

Bubble aluminium foil insulation is a practical, lightweight, and efficient solution for managing indoor temperatures. Its reflective properties, ease of installation, and versatility make it suitable for roofs, walls, and windows. When selected and installed correctly, it provides long-term comfort while supporting energy efficiency goals.

FAQ’S

Bubble Aluminium Foil Insulation is used to reduce radiant heat transfer in roofs, walls, and windows. It helps maintain indoor comfort by reflecting heat away from the building envelope.

Yes, bubble foil works as thermal insulation by combining air-filled bubbles with reflective aluminium foil. This structure limits heat movement and improves overall thermal resistance when installed correctly

Bubble wrap insulation for windows is commonly used to reduce heat gain through glass, especially in areas exposed to direct sunlight. It is lightweight and easy to install.

Bubble foil is thinner and lighter than conventional insulation materials. While it reflects radiant heat efficiently, it is often combined with other insulation types for higher performance.

Thermal insulation price in Pakistan depends on material type, foil quality, number of layers, roll size, and installation requirements.