Karachi’s climate is dominated by intense sunlight, high humidity, and long summers. Without proper insulation, indoor temperatures can rise dramatically, increasing electricity bills and reducing comfort. Choosing the best insulation sheets in Karachi is no longer optional—it’s a necessity for homes, warehouses, factories, and commercial buildings.

This guide explains top insulation sheet options, pricing factors, applications, and how to select the right solution for Karachi’s extreme weather conditions.

Why Insulation Sheets Are Essential in Karachi

Karachi experiences prolonged heat waves, especially from April to October. Roofs and walls absorb excessive heat, which transfers directly indoors.

High-quality heat insulation sheet in Pakistan helps by:

- Reducing roof surface temperature

- Lowering indoor heat gain

- Minimizing air-conditioning load

- Improving year-round energy efficiency

For both residential and industrial use, insulation sheets offer long-term cost savings and comfort.

Types of Insulation Sheets Commonly Used in Karachi

Several insulation materials are available in the local market, but performance varies depending on structure, thickness, and installation quality.

1. Thermopore Insulation Sheets

Thermopore is widely used due to affordability and availability.

Key Features:

- Lightweight and easy to install

- Suitable for roofs, walls, and false ceilings

- Commonly used in residential construction

Many buyers search for a thermopore sheet supplier in Karachi because local availability reduces transportation cost and delivery time.

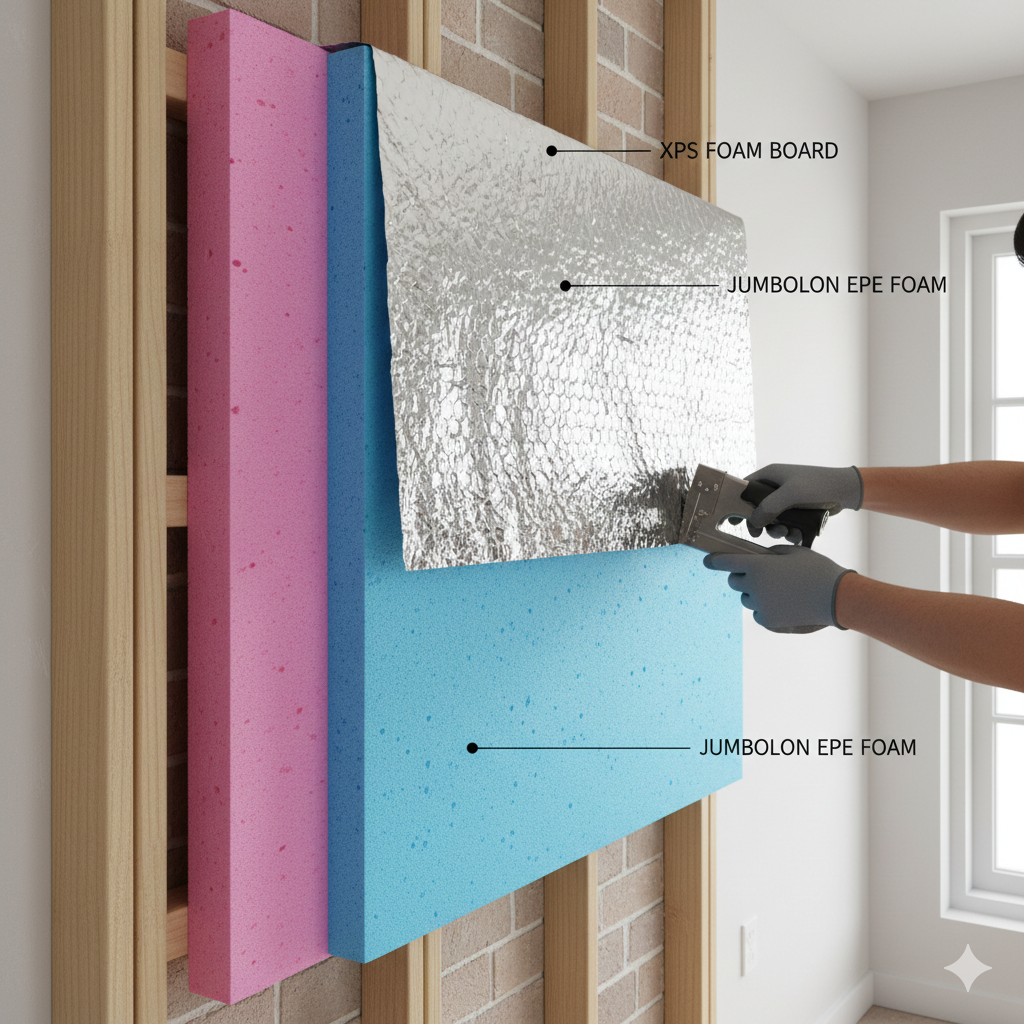

2. Reflective Thermal Insulation Sheets

These sheets combine insulation foam with aluminum foil to reflect radiant heat.

Advantages:

- Strong heat reflection

- Ideal for rooftops exposed to direct sunlight

- Performs better than plain foam in extreme heat

They are often considered among the best insulation sheets in Karachi price-wise when energy savings are considered.

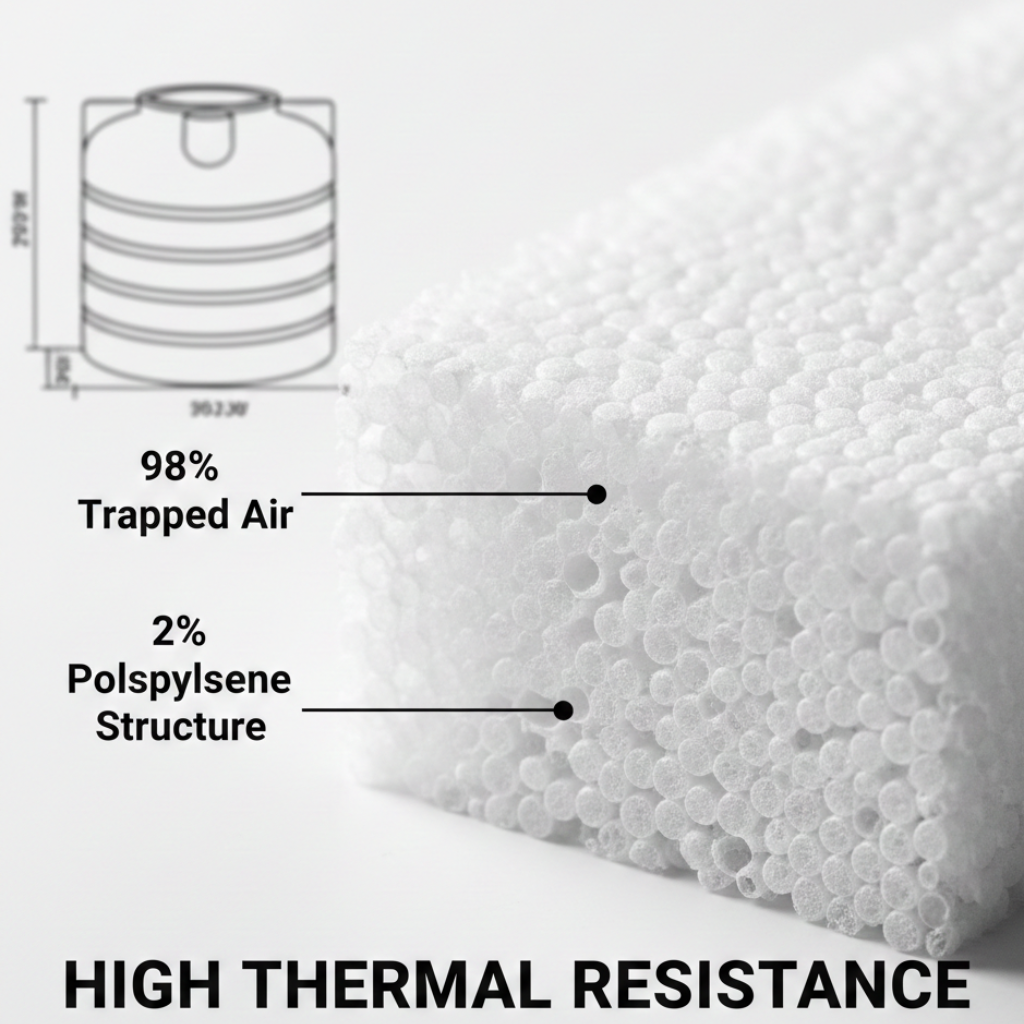

3. Expanded Polystyrene (EPS) Sheets

EPS sheets offer balanced thermal insulation and structural stability.

Best used for:

- Warehouses

- Cold rooms

- Commercial buildings

EPS is commonly included when comparing thermal insulation sheet price in Pakistan due to its consistent performance.

Thermopore Sheets in Karachi – Availability & Demand

The demand for thermopore sheet in Karachi continues to grow due to urban expansion and rising energy costs.

These sheets are commonly installed in:

- Residential rooftops

- Industrial sheds

- Temporary structures

People often search online for thermopore sheet near me, indicating strong local demand for quick sourcing and installation services.

Heat Insulation Sheet Performance in Pakistan’s Climate

A properly installed heat insulation sheet in Pakistan can reduce indoor temperature by several degrees. Performance depends on:

- Sheet thickness

- Roof exposure

- Installation method

- Combination with reflective layers

For Karachi’s coastal climate, moisture resistance and durability are equally important.

Pricing Overview – What Affects Insulation Sheet Cost?

The best insulation sheets in Karachi price range depends on multiple factors:

- Material type (thermopore, EPS, reflective)

- Sheet thickness

- Density and durability

- Installation requirements

- Market demand fluctuations

Similarly, thermopore sheet price in Pakistan may vary city-to-city due to logistics and supplier margins.

How to Choose the Best Insulation Sheet in Karachi

When selecting insulation, consider the following:

Climate Suitability

Karachi requires insulation that resists both heat and humidity.

Installation Area

Roofs require higher thermal resistance compared to walls.

Budget vs Long-Term Savings

Low-cost insulation may increase cooling expenses over time.

Supplier Reliability

Working with a verified thermopore sheet supplier in Karachi ensures product quality and technical guidance.

Residential vs Commercial Insulation Needs

| Application | Recommended Insulation |

|---|---|

| Homes | Thermopore or reflective sheets |

| Shops | EPS or foil insulation |

| Factories | High-density thermal sheets |

| Warehouses | EPS with reflective layers |

Each option balances cost, durability, and performance differently.

Installation Tips for Maximum Heat Reduction

- Always install insulation before waterproofing

- Seal gaps to prevent air leakage

- Use foil-faced sheets for rooftops

- Avoid compressing insulation material

Correct installation often matters more than material thickness alone.

Final Verdict – Which Insulation Sheet Is Best for Karachi?

There is no single solution for every building. However:

- Thermopore remains the most accessible option

- Reflective insulation delivers better heat reduction

- EPS offers long-term durability

Choosing the right product depends on roof design, usage, and budget.

FAQ’S

The best insulation sheets in Karachi include thermopore sheets, reflective insulation sheets, and EPS sheets. These materials are designed to reduce roof heat absorption and improve indoor comfort in Karachi’s hot and humid climate.

Thermopore sheet price in Pakistan depends on thickness, density, and supplier location. Prices in Karachi may differ slightly due to transportation and local demand, so it’s recommended to consult a nearby supplier for updated rates.

A reliable thermopore sheet supplier in Karachi can be found through building material markets, insulation dealers, and authorized distributors who provide proper thickness guidance and installation support.

Yes, a quality heat insulation sheet in Pakistan can significantly reduce indoor temperature, especially when installed on rooftops. It helps lower electricity consumption by reducing the load on cooling systems.

Thermal insulation sheet price in Pakistan varies based on material type, sheet thickness, durability, and whether the insulation includes reflective foil layers. EPS and reflective sheets generally cost more than basic thermopore.

A thermopore sheet near me is suitable for long-term use when installed correctly and protected from moisture and direct exposure. Proper sealing and layering improve its lifespan and performance.