High-temperature industries in Pakistan require insulation materials that can withstand extreme heat without losing performance. This is where ceramic fibre insulation plays a critical role. Used primarily in furnaces, kilns, boilers, and industrial plants, ceramic fibre insulation offers superior thermal resistance compared to conventional materials.

This guide explains everything you need to know about ceramic fibre insulation in Pakistan, including pricing, applications, material forms, and how it compares with glass wool and fibreglass insulation.

What Is Ceramic Fibre Insulation?

Ceramic fibre insulation is a high-temperature resistant material manufactured from alumina-silica fibers. It is designed to perform in environments where conventional insulation materials fail due to extreme heat.

Ceramic fibre insulation is commonly available in blanket, board, paper, and module forms, with ceramic wool insulation being one of the most widely used variants.

Why Ceramic Fibre Insulation Is Used in Pakistan

Ceramic fibre insulation is gaining importance in Pakistan due to:

- Growing industrial sector

- Demand for energy-efficient furnaces and kilns

- High operating temperatures in steel, cement, and power plants

- Long service life in extreme conditions

Industries prefer ceramic fibre insulation where standard thermal solutions are not suitable.

Ceramic Fibre Insulation in Pakistan Price – What Influences Cost?

The ceramic fibre insulation in Pakistan price depends on multiple factors, including:

- Temperature rating

- Density and thickness

- Product form (blanket, board, module)

- Imported vs locally available material

- Application type

Because of these variables, prices are usually quoted per roll, per square meter, or per kilogram depending on product form.

Ceramic Wool Insulation – Common Industrial Choice

Ceramic wool insulation is widely used in high-temperature industrial applications due to its lightweight structure and excellent heat resistance. It helps reduce heat loss, improve process efficiency, and lower fuel consumption in furnaces and kilns.

Ceramic wool is often selected when fast installation and high thermal performance are required.

Ceramic Fiber Blanket Price in Pakistan

The ceramic fiber blanket price in Pakistan varies depending on thickness and temperature rating. Higher temperature grades typically cost more due to increased alumina content and manufacturing complexity.

Ceramic fiber blankets are commonly used in:

- Industrial furnaces

- Boilers and heaters

- Expansion joints

- Heat treatment equipment

Ceramic Fibre Insulation in Karachi – Market Overview

Demand for ceramic fibre insulation in Karachi is strong due to the city’s concentration of industrial zones, power plants, and manufacturing units. Availability is generally better in Karachi compared to smaller cities, although pricing may vary due to import logistics.

Comparison With Fibreglass and Glass Wool Insulation

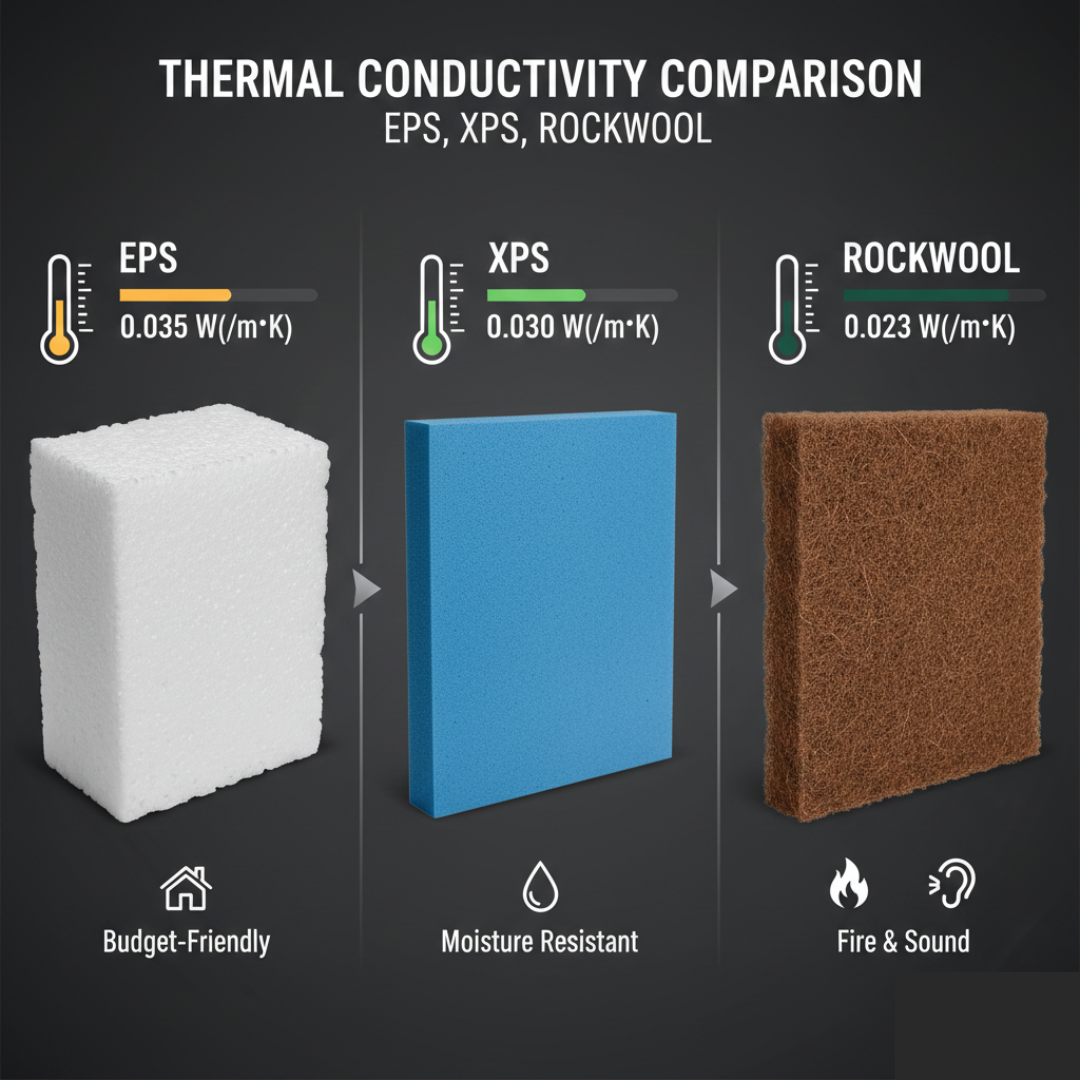

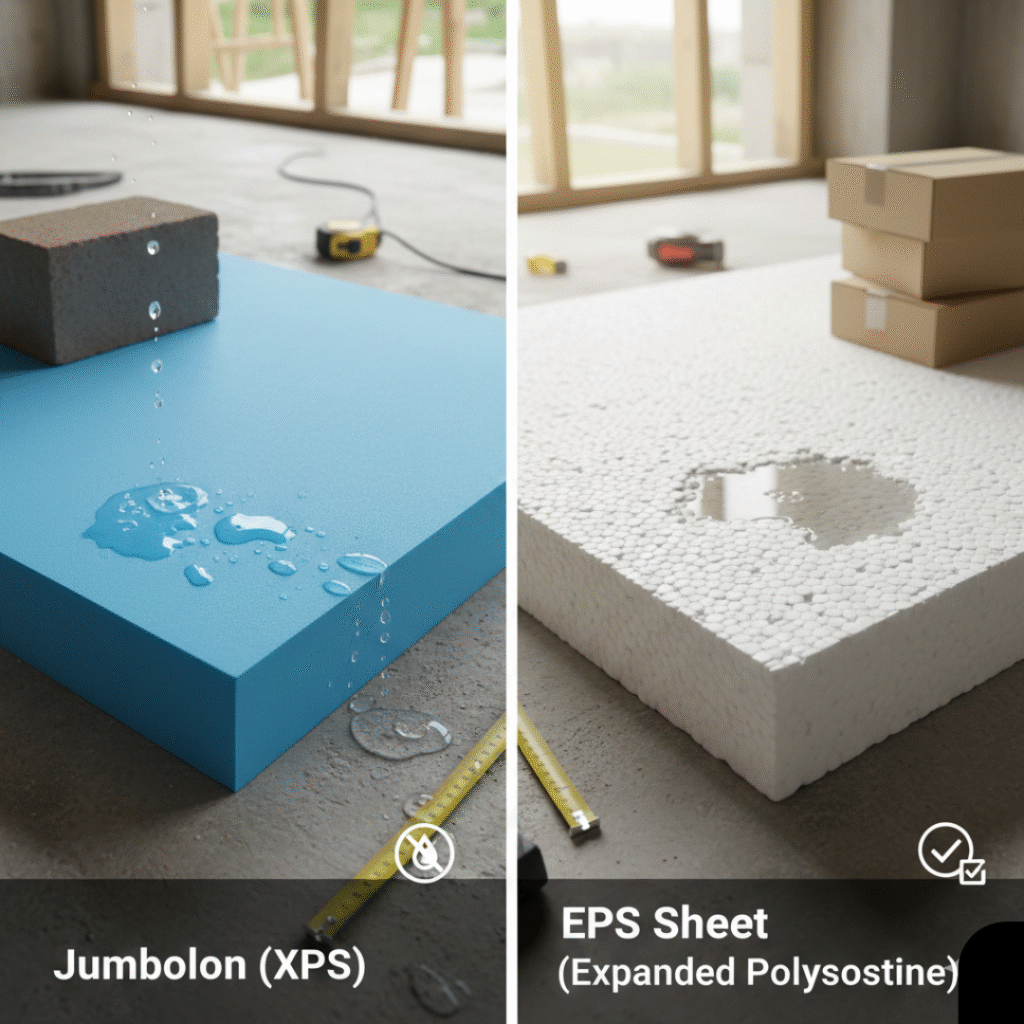

Ceramic fibre insulation is often compared with conventional insulation materials.

- Fibreglass insulation price in Pakistan is significantly lower, but fibreglass is not suitable for very high temperatures.

- Glass wool insulation price is also more affordable, making it suitable for buildings and light industrial use rather than furnaces.

Ceramic fibre insulation is chosen specifically for extreme heat applications, while fibreglass and glass wool are used for general thermal insulation.

Best Ceramic Fibre Insulation in Pakistan – How to Choose

Selecting the best ceramic fibre insulation in Pakistan depends on:

- Maximum operating temperature

- Type of industrial process

- Installation environment

- Long-term durability requirements

Higher-grade ceramic fibre materials offer better resistance to shrinkage and thermal shock, making them suitable for critical industrial applications.

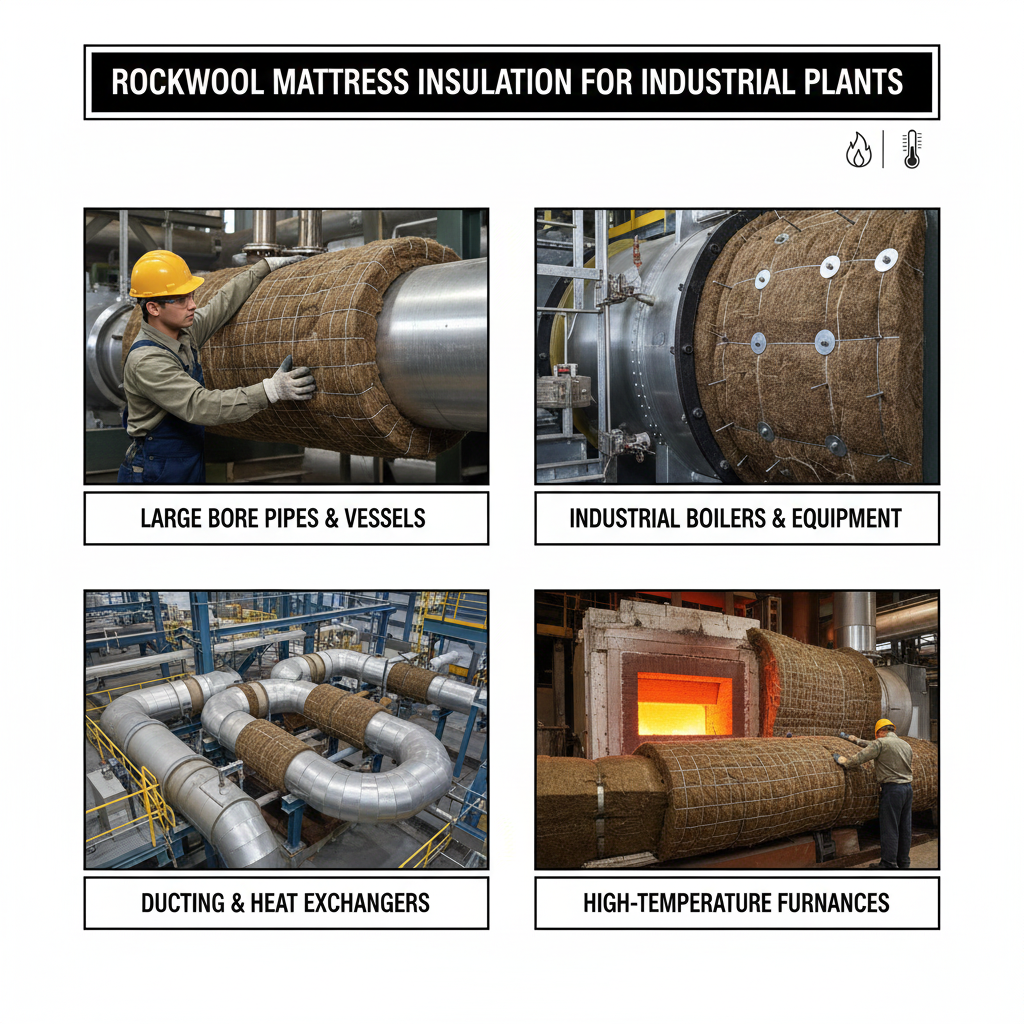

Applications of Ceramic Fibre Insulation

Ceramic fibre insulation is commonly used in:

- Industrial furnaces and kilns

- Boilers and heat exchangers

- Steel and metal processing plants

- Power generation units

- Petrochemical industries

Its performance in extreme conditions makes it indispensable in these sectors.

Long-Term Benefits of Ceramic Fibre Insulation

Despite higher initial cost, ceramic fibre insulation offers long-term benefits such as:

- Reduced energy consumption

- Faster heat-up and cool-down cycles

- Improved process efficiency

- Lower maintenance costs

These benefits make ceramic fibre insulation a cost-effective solution over time.

Final Thoughts

Understanding ceramic fibre insulation in Pakistan helps industrial buyers make informed decisions. While it is more expensive than fibreglass or glass wool insulation, its performance at high temperatures makes it irreplaceable in industrial environments.

Choosing the right grade and professional installation ensures safety, efficiency, and long-term value.

FAQ’S

Ceramic fibre insulation is mainly used in high-temperature industrial applications such as furnaces, kilns, boilers, and heat treatment plants where conventional insulation materials cannot withstand extreme heat.

Ceramic fibre insulation is designed for very high temperatures, while glass wool and fibreglass insulation are suitable for buildings and low to medium temperature applications. Each material serves a different purpose.

Price depends on temperature rating, thickness, density, product type (blanket or board), and whether the material is locally sourced or imported.

Ceramic fibre insulation is commonly available in major industrial cities such as Karachi, Lahore, and Faisalabad through industrial insulation suppliers.