Efficient HVAC systems depend heavily on proper duct insulation. In Pakistan’s hot summers and humid conditions, energy losses through uninsulated or poorly insulated ducts can significantly increase electricity costs. This is where Glasswool & Aluminium Foil for Duct Insulation becomes a practical and cost-effective solution for residential, commercial, and industrial buildings.

This guide explains how glasswool combined with aluminium foil works, why it is widely used, and what buyers in Pakistan should know before choosing duct insulation materials.

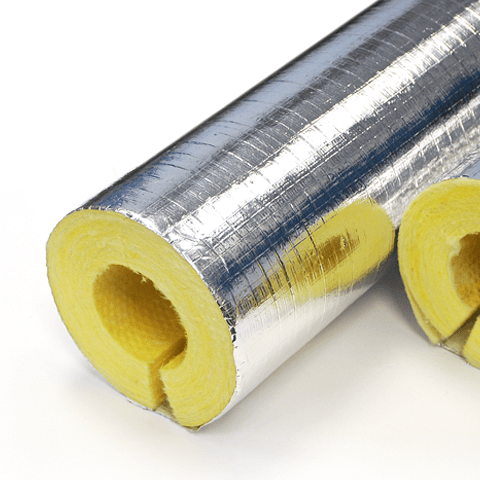

What Is Glasswool & Aluminium Foil Duct Insulation?

Glasswool insulation is a fibrous material manufactured from recycled glass, designed to trap air and reduce heat transfer. When paired with a reflective aluminium foil facing, it becomes a highly efficient insulation system for HVAC ducts.

In Glasswool & Aluminium Foil for Duct Insulation Pakistan, this combination is preferred because it offers both thermal resistance and vapor barrier protection, helping ducts perform efficiently in varied climate conditions.

How Glasswool with Aluminium Foil Works in HVAC Systems

The performance of glasswool insulation with aluminium foil comes from a dual-action mechanism:

- Glasswool fibers slow down heat flow by trapping air

- Aluminium foil reflects radiant heat and blocks moisture vapor

Together, they help maintain consistent air temperature inside ducts while reducing condensation and energy loss.

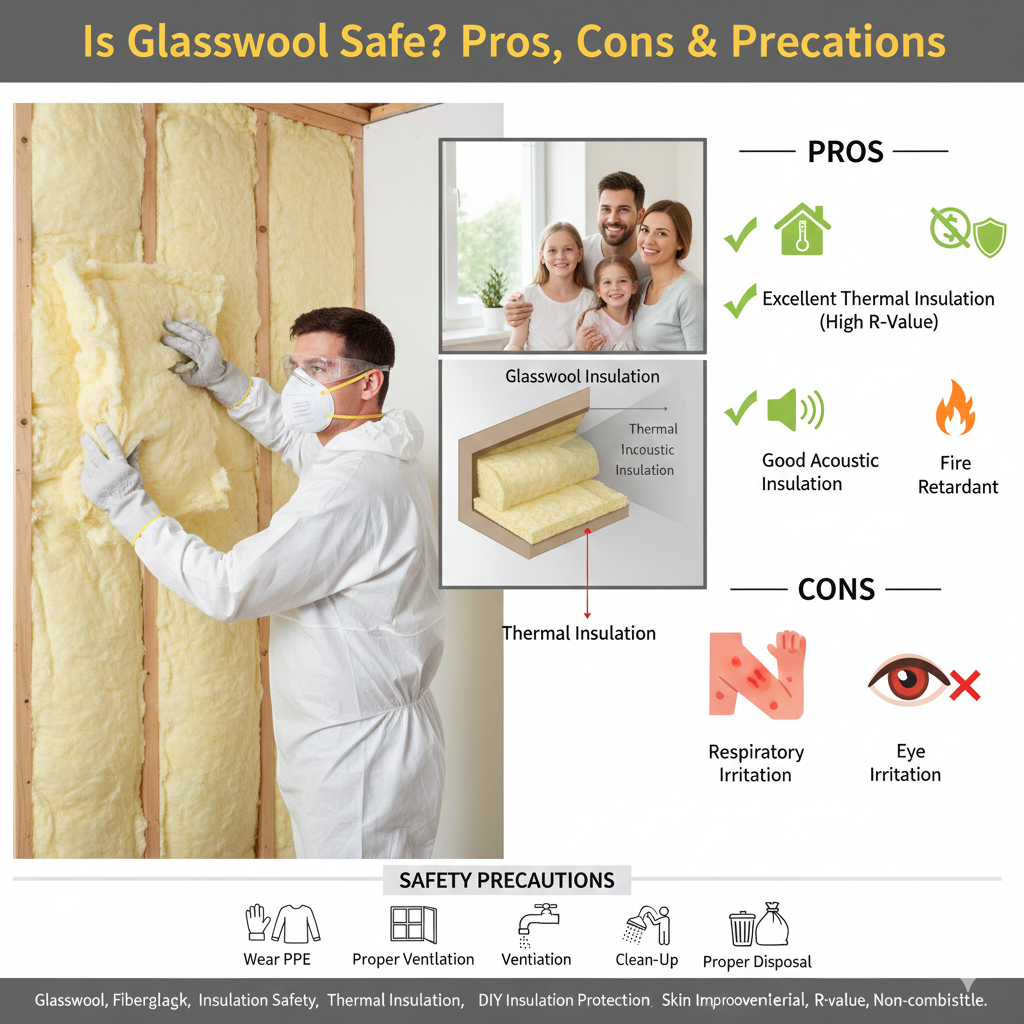

Benefits of Glasswool Duct Insulation

1. Thermal Efficiency

Glasswool duct insulation helps keep cooled or heated air at the desired temperature as it travels through ducts, improving overall HVAC efficiency.

2. Moisture & Condensation Control

The foil facing acts as a vapor barrier, making aluminium foil duct insulation especially useful in humid environments.

3. Lightweight & Flexible Installation

Glasswool blankets are easy to cut, wrap, and install around circular or rectangular ducts without adding excessive load.

4. Noise Reduction

Apart from thermal performance, glasswool also absorbs sound, reducing noise generated by air movement inside ducts.

Glasswool Blanket with Aluminium Foil – Common Applications

A glasswool blanket with aluminium foil is widely used in:

- Central air-conditioning ducts

- Commercial HVAC systems

- Industrial ventilation ducts

- Hospitals, malls, offices, and hotels

Its flexibility makes it suitable for both new installations and retrofit projects.

Why Aluminium Foil Facing Is Important

Aluminium foil is not just a covering; it plays a functional role in insulation systems:

- Reflects radiant heat

- Prevents moisture ingress

- Enhances durability of glasswool

- Improves hygiene in HVAC systems

This makes foil-faced insulation ideal for long-term duct performance.

Thickness & Density Considerations

Choosing the right thickness and density depends on:

- Indoor vs outdoor duct placement

- Temperature difference between air and surroundings

- Energy efficiency requirements

Higher thickness generally improves insulation but should be selected according to project needs rather than over-specification.

Common Duct & Insulation Materials (Pakistan)

| Insulation Material | Thermal Performance | Moisture Resistance | Acoustic Control | Relative Price |

|---|---|---|---|---|

| Glasswool + Aluminium Foil | High | High (foil-faced) | Good | Medium |

| EPS / Thermocol Sheet | Medium | Low | Low | Low |

| Jumbolon Foam Sheet | Medium–High | High | Medium | Medium–High |

Note: Prices vary by city, thickness, and supplier. Always compare specifications instead of price alone.

Glasswool & Aluminium Foil for Duct Insulation Price Factors

The Glasswool & Aluminium Foil for Duct Insulation price depends on several variables:

- Glasswool density and thickness

- Type and quality of aluminium foil

- Roll size and brand

- Project quantity

In local markets, Glasswool & Aluminium Foil for Duct Insulation price in Pakistan can vary by city and supplier, so comparing specifications is more important than focusing only on cost.

Glasswool vs Other Duct Insulation Materials

Compared to alternatives like elastomeric foam or rigid boards, glasswool with foil offers a balanced solution:

- Better coverage for large duct networks

- Competitive pricing for commercial projects

- Strong thermal and acoustic performance

This makes it a popular choice for HVAC contractors across Pakistan.

Installation Best Practices

For optimal performance:

- Ensure joints are sealed properly

- Avoid compressing the glasswool layer

- Maintain foil continuity for vapor control

- Use appropriate tapes and fasteners

Correct installation is as important as the insulation material itself.

Conclusion

Glasswool combined with aluminium foil remains one of the most practical solutions for duct insulation in Pakistan. Its ability to reduce heat loss, control condensation, and improve HVAC efficiency makes it suitable for a wide range of applications. By selecting the right specifications and ensuring proper installation, long-term energy savings and system performance can be achieved.

FAQ’S

Glasswool & aluminium foil for duct insulation is used to reduce heat loss, prevent condensation, and improve energy efficiency in HVAC air-conditioning and ventilation ducts.

Yes, glasswool insulation with aluminium foil is ideal for Pakistan’s hot and humid climate because the foil acts as a vapor barrier while glasswool provides strong thermal resistance.

Commonly used thicknesses range from 25mm to 50mm, depending on whether the duct is indoor or outdoor and the required energy efficiency level.

Yes, aluminium foil duct insulation significantly reduces condensation by blocking moisture vapor from entering the insulation layer.

Glasswool duct insulation absorbs sound vibrations, helping to reduce HVAC noise and improve indoor acoustic comfort.

The price depends on thickness, density, foil quality, roll size, brand, and total project quantity.