Choosing the right insulation for a home is no longer optional—it’s essential for comfort, energy efficiency, and long-term cost savings. Among the many insulation options available today, EPS, XPS, and Glasswool stand out as a powerful combination for residential buildings. This blog explains why EPS, XPS, Glasswool: Best Mix for Homes is a smart insulation strategy and how each material contributes to thermal, acoustic, and fire performance.

Why Modern Homes Need a Combination of Insulation Materials

No single insulation material can perfectly address heat control, soundproofing, moisture resistance, and fire safety at the same time. That’s why combining materials has become a best practice in modern construction.

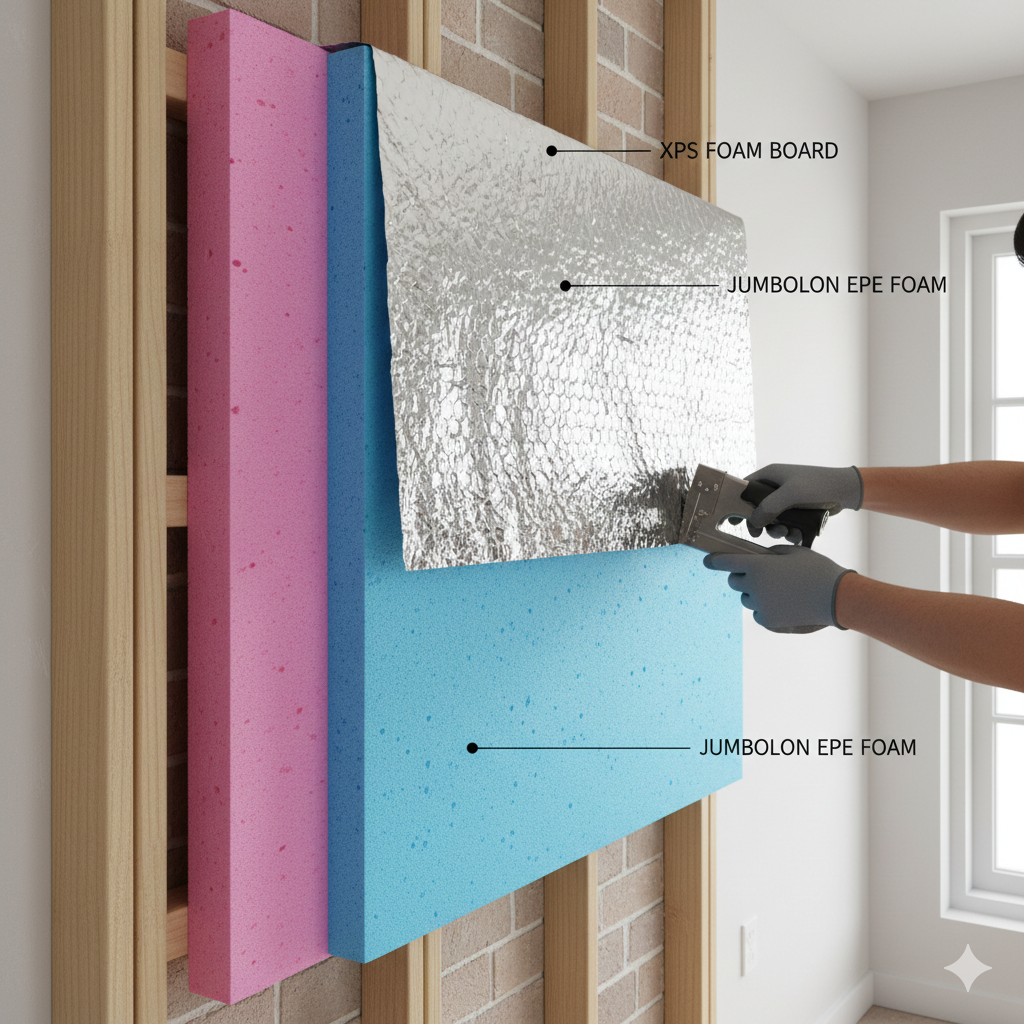

Using EPS for walls, XPS for roofs and foundations, and Glasswool for ceilings and partitions creates a balanced system that enhances indoor comfort without excessive cost.

Understanding EPS, XPS, and Glasswool

What is EPS Insulation?

Expanded Polystyrene (EPS) is a lightweight insulation material widely used in walls and floors. It provides effective thermal insulation and is easy to install, making it popular in residential projects.

Key Benefits of EPS:

- Cost-effective thermal insulation

- Lightweight and easy to handle

- Suitable for wall cavities and floor insulation

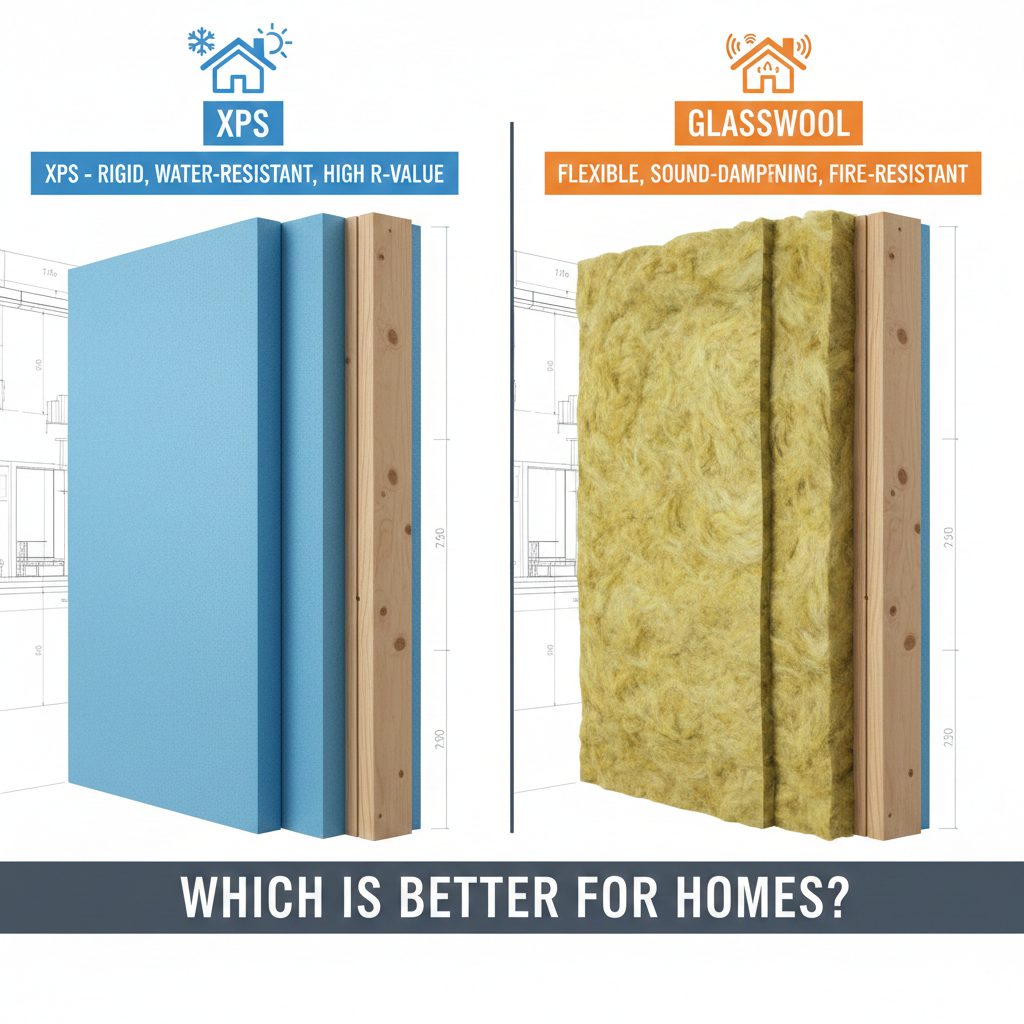

What is XPS Insulation?

Extruded Polystyrene (XPS) offers higher density and better moisture resistance than EPS. It is ideal for areas exposed to water or heavy loads.

Why XPS is Ideal for Homes:

- Strong moisture resistance

- High compressive strength

- Excellent for roofs and foundations

What Is Glass Mineral Wool Insulation?

Many homeowners ask, what is glass mineral wool insulation?

Glass mineral wool is a fibrous insulation made from recycled glass, designed to trap air and reduce heat and sound transfer. It is commonly used in ceilings, partitions, and internal walls.

Glass Wool Performance Explained

Glass Wool Fire Resistance

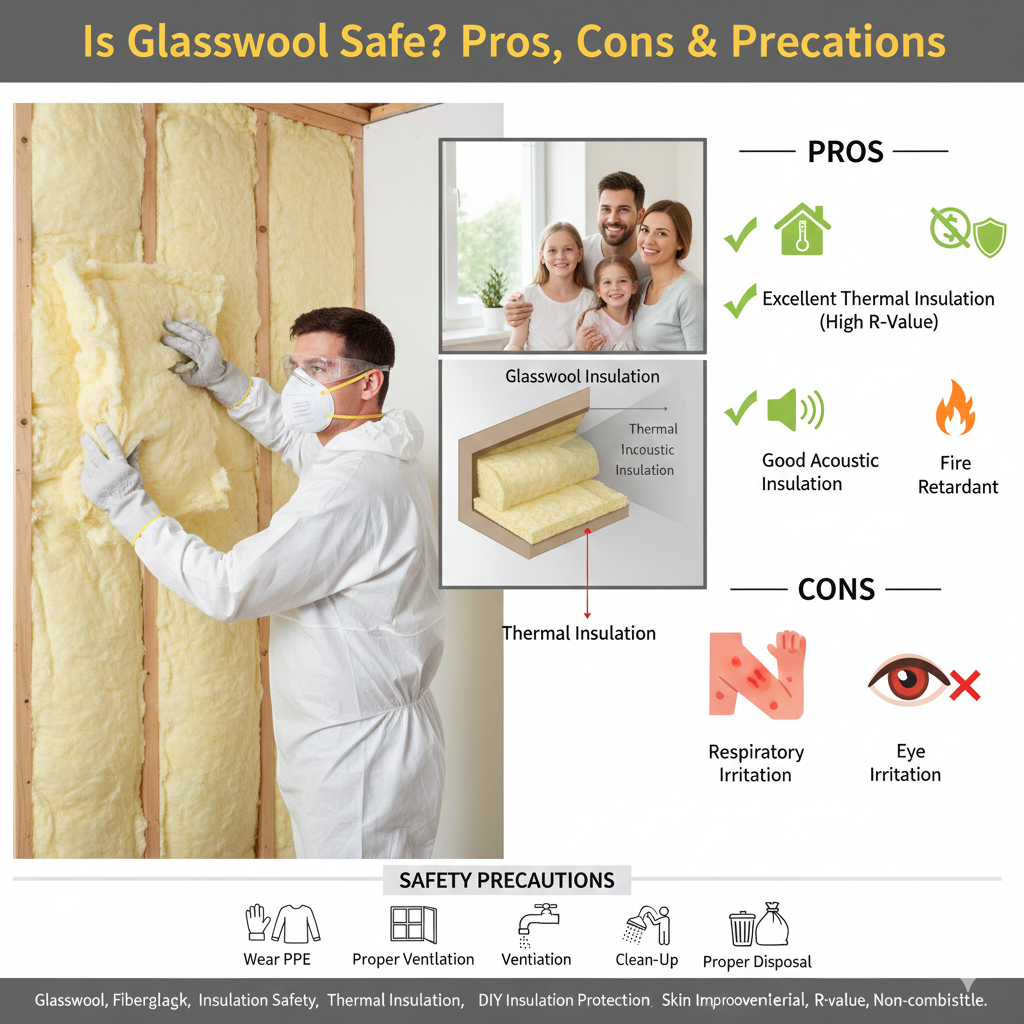

One of the strongest advantages of glass wool is its fire safety. Glass wool fire resistance is high because it is non-combustible and can withstand extreme temperatures without spreading flames. This makes it a reliable choice for residential safety.

Is Glass Wool Dangerous?

A common concern is whether glass wool dangerous for homes. When installed correctly and sealed behind walls or ceilings, glass wool is safe. Modern manufacturing standards have significantly reduced health risks, making it suitable for residential use.

Soundproofing Comparison: Glasswool vs Rockwool

Rockwool vs Glasswool Soundproofing

When comparing rockwool vs glasswool soundproofing, both materials perform well, but glass wool is often preferred for residential spaces due to its lighter weight and easier installation.

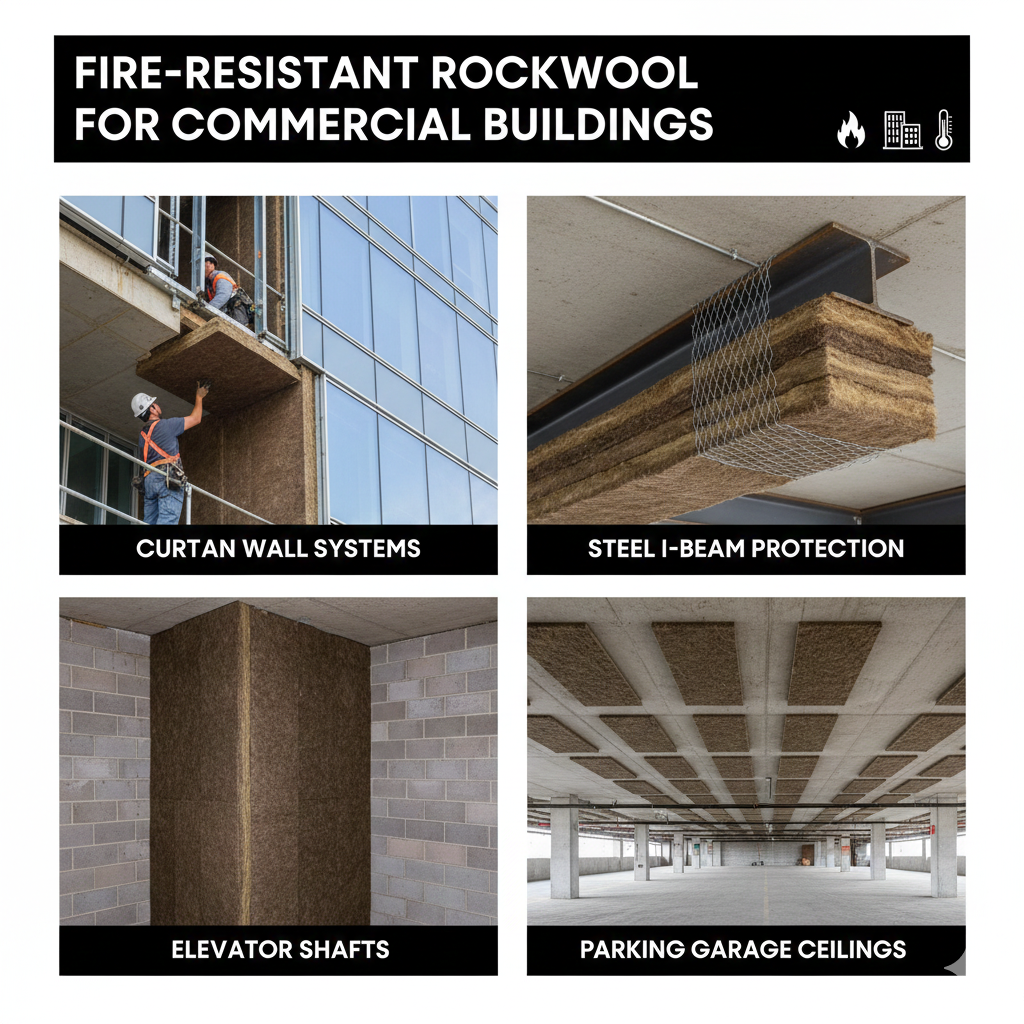

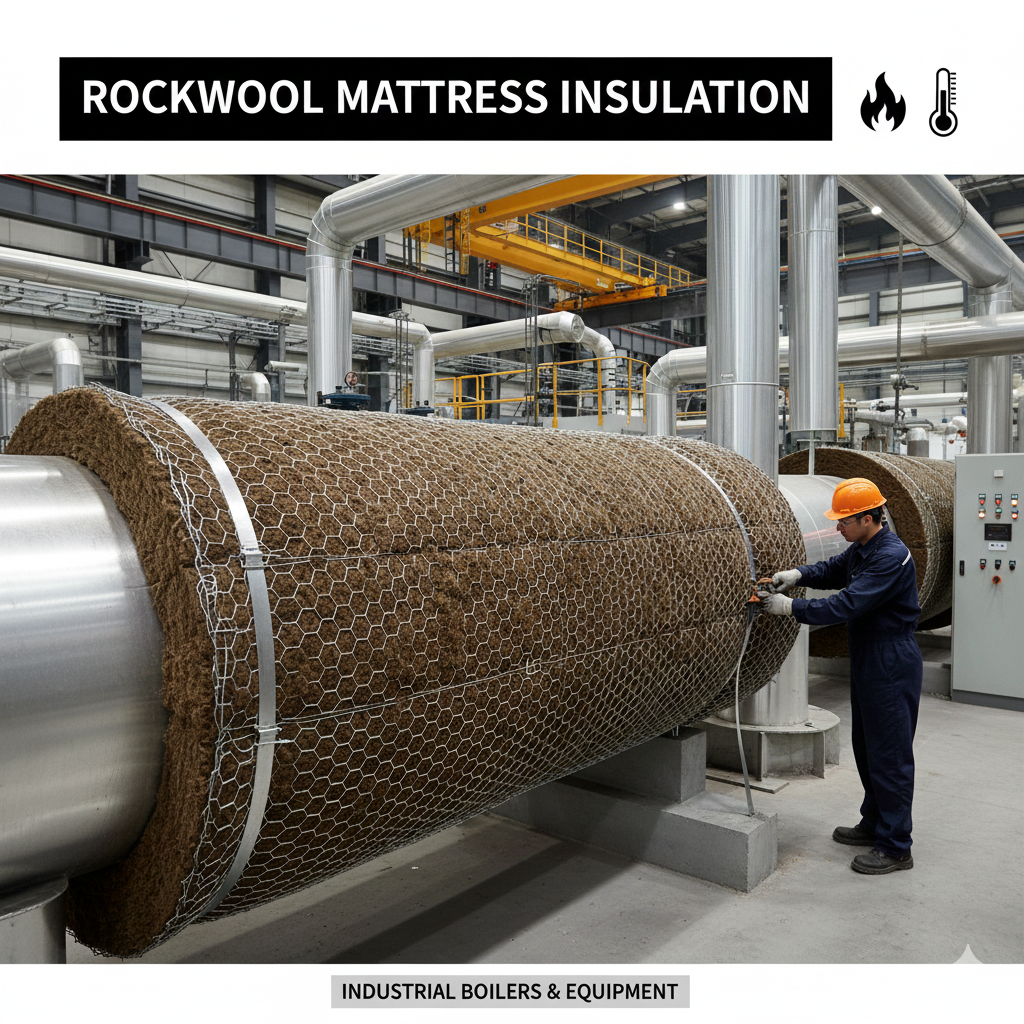

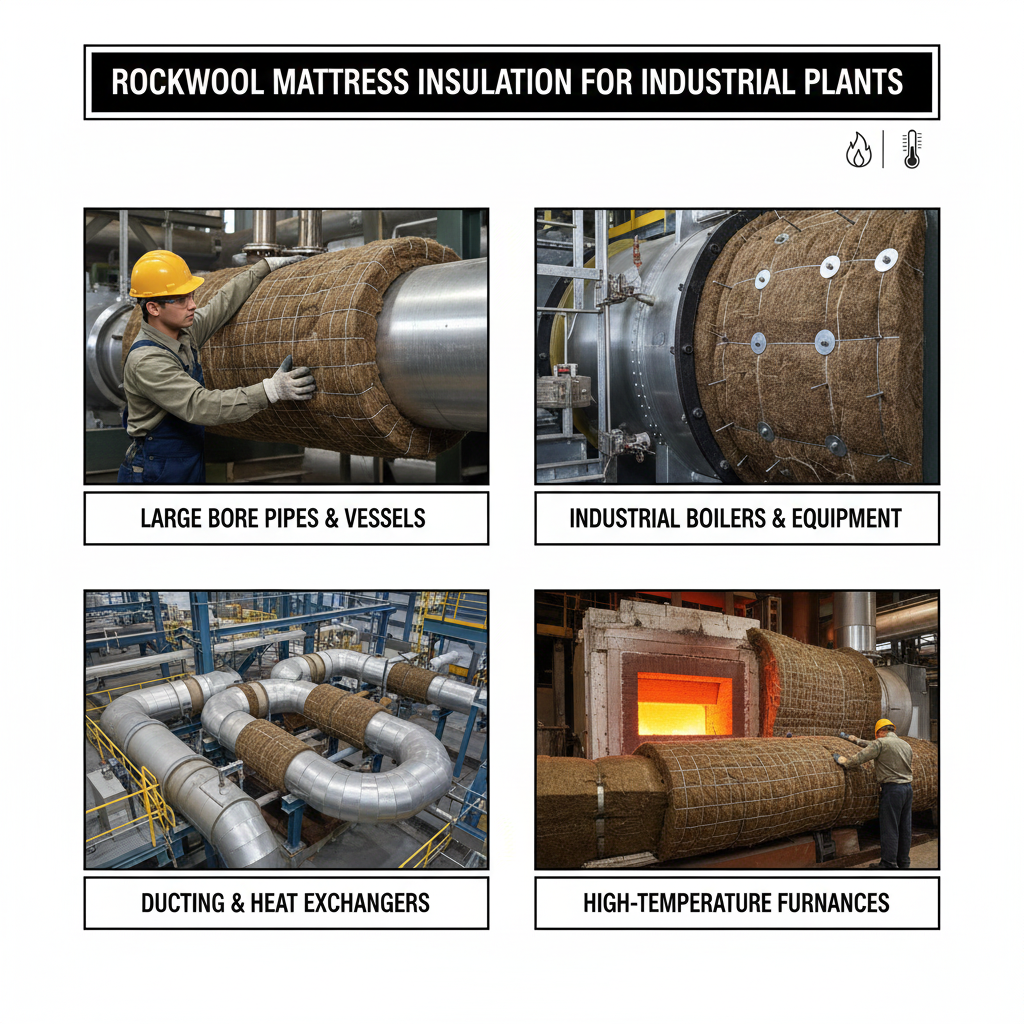

Glass Mineral Wool vs Rockwool

The debate of glass mineral wool vs rockwool comes down to application. Glass mineral wool is ideal for ceilings and partitions, while rockwool is often chosen for industrial or heavy-duty acoustic applications.

Cost Comparison and Pricing Factors

Glass Wool vs Rock Wool Price

In terms of affordability, glass wool vs rock wool price generally favors glass wool for residential projects. Glass wool offers a lower upfront cost while still delivering strong thermal and acoustic performance.

Glass Wool Insulation Price

The glass wool insulation price depends on thickness, density, and application area. For homes, it remains one of the most economical insulation solutions, especially when combined with EPS and XPS.

Floor and Structural Applications

Mineral Wool Floor Insulation

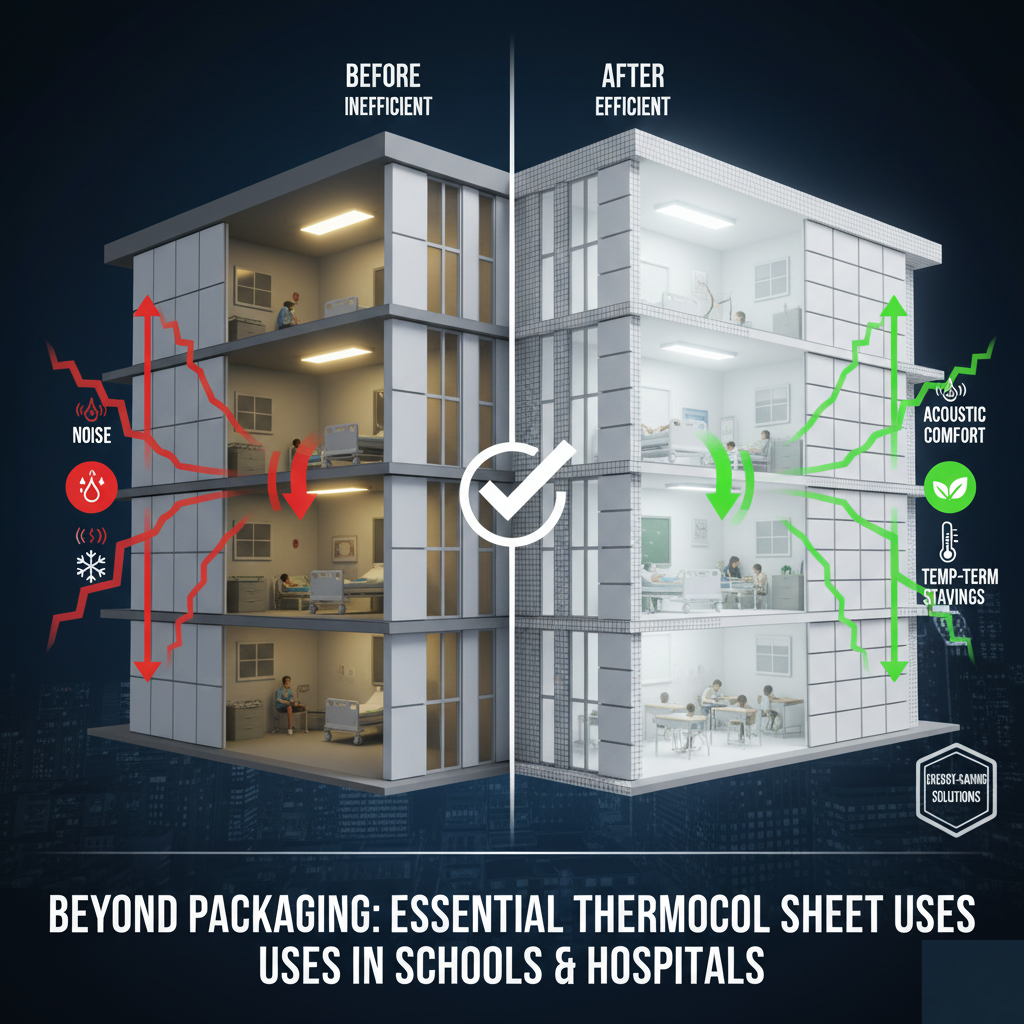

Using mineral wool floor insulation helps reduce impact noise and heat loss between floors. In multi-story homes, it significantly improves acoustic comfort while maintaining thermal efficiency.

Why EPS, XPS, Glasswool Is the Best Mix for Homes

Combining these materials allows homeowners to target specific insulation needs:

- EPS for walls and floors

- XPS for roofs, terraces, and foundations

- Glasswool for ceilings, partitions, and sound control

This strategic combination ensures thermal stability, sound reduction, moisture protection, and fire safety—all without overspending.

How to Choose the Right Insulation Mix for Your Home

Before selecting insulation, consider:

- Local climate conditions

- Noise levels

- Budget constraints

- Fire safety requirements

Professionals often recommend the EPS, XPS, Glasswool: Best Mix for Homes because it balances performance and cost effectively.

Conclusion

A well-insulated home is more comfortable, energy-efficient, and safer. By combining EPS, XPS, and glass wool, homeowners achieve superior insulation performance across all areas of the house. Understanding factors like rockwool vs glasswool soundproofing, glass wool fire resistance, and glass wool insulation price helps in making an informed decision.

If you’re planning a new home or upgrading insulation, this combination offers long-term value and dependable performance.

FAQ’S

This combination works well because each material serves a specific purpose. EPS is ideal for walls and floors, XPS performs best in roofs and moisture-prone areas, while glass wool improves thermal and acoustic comfort inside the home.

Glass mineral wool insulation is commonly used in ceilings, partitions, and cavity walls. It helps reduce heat transfer and improves indoor sound insulation without adding heavy load to the structure.

Glass wool is safe for homes when installed correctly. Modern glass wool products are designed to meet safety standards, and once sealed behind walls or ceilings, there is no health risk.

Glass wool fire resistance is high because it is non-combustible. It does not support flame spread and helps slow down heat transfer during a fire, making it suitable for residential buildings.

When comparing rockwool vs glasswool soundproofing, both are effective. Glass wool is generally preferred in homes due to its lighter weight and easier installation, while rockwool is often used in industrial or high-noise environments.

The main difference between glass mineral wool vs rockwool lies in density and application. Glass mineral wool is lighter and more flexible, whereas rockwool is denser and better suited for heavy-duty insulation needs.