Introduction

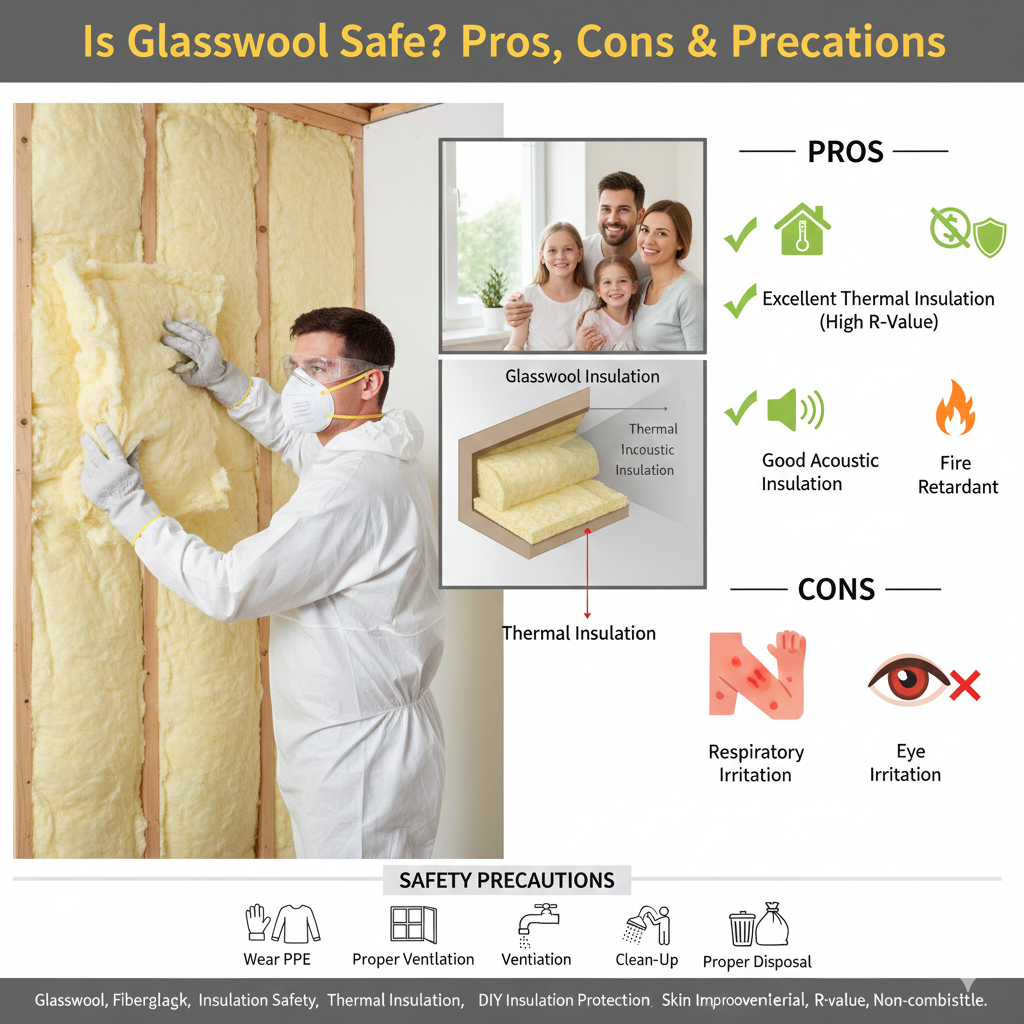

When considering home improvement projects or new construction, thermal insulation is a critical component for energy efficiency and indoor comfort. Among the most widely used building material options for insulation is Glasswool insulation, often referred to as fiberglass. Its prevalence is due to its excellent thermal insulation properties and relatively low cost.

However, many homeowners and DIY enthusiasts often ask: “Is Glasswool safe?” This is a valid concern, given its fibrous nature and the dust it can generate. This guide will delve into the composition of Glasswool, its benefits, potential drawbacks, and, most importantly, the essential safety precautions to ensure a safe experience during installation and in daily living.

What is Glasswool (Fiberglass) Insulation?

Glasswool is a type of mineral wool made from extremely fine fibers of glass. The manufacturing process involves melting recycled glass and sand, then spinning it into fibers, which are then bound together with a resin and formed into batts, rolls, or loose-fill. The tiny air pockets trapped within these fibers are what provide its superior thermal insulation and decent acoustic insulation properties.

It’s primarily used in walls, ceilings, and floors to reduce heat transfer, lower energy bills, and improve overall interior comfort.

The Benefits of Using Glasswool

Despite the safety questions, Glasswool remains popular for several good reasons:

1. Excellent Thermal Insulation

Glasswool is highly effective at resisting heat flow, boasting a good R-value (a measure of thermal resistance) per inch. This makes it an efficient building material for keeping homes warm in winter and cool in summer, leading to significant energy savings.

2. Cost-Effective

Compared to some other insulation material options, Glasswool is generally more affordable, making it a budget-friendly choice for many DIY insulation projects and large-scale constructions.

3. Good Acoustic Insulation

Beyond thermal properties, the fibrous structure of Glasswool also provides reasonable acoustic insulation, helping to dampen sound transmission between rooms and from outside, contributing to a quieter indoor environment.

4. Fire Retardant Properties

While not entirely non-combustible like stone wool, Glasswool is resistant to fire and does not typically contribute to the spread of flames. It has good fire-retardant properties, offering an added layer of safety in a building’s fire strategy.

Potential Concerns: Addressing the Safety Question

The main concerns regarding the safety of Glasswool stem from the tiny glass fibers themselves:

1. Skin Irritation

The most common issue encountered with Glasswool is skin irritation. The microscopic glass fibers can embed themselves in the skin, causing itching, redness, and discomfort. This is a physical irritation, not a chemical reaction, and is temporary.

2. Respiratory Irritation

When disturbed, Glasswool can release fine airborne fibers. Inhaling these fibers can irritate the upper respiratory tract, leading to coughing, sneezing, or a sore throat. For individuals with existing respiratory conditions like asthma, this can be particularly bothersome. However, extensive research by organizations like the World Health Organization (WHO) and the International Agency for Research on Cancer (IARC) has concluded that modern Glasswool fibers are not classifiable as to their carcinogenicity to humans, meaning they are not considered a cancer risk. The fibers are non-respirable, meaning they are too large to reach the deep lung tissue.

3. Eye Irritation

Fibers can also get into the eyes, causing discomfort, redness, and a gritty sensation.

Essential Safety Precautions for Handling Glasswool

The key to safe installation and handling of Glasswool lies in proper safety precautions. These measures are simple but crucial for minimizing exposure and discomfort.

1. Personal Protective Equipment (PPE)

- Gloves: Always wear heavy-duty work gloves to prevent skin irritation.

- Long Sleeves and Pants: Cover all exposed skin. Wear loose-fitting, long-sleeved shirts and long pants, ideally disposable coveralls for extensive work.

- Eye Protection: Goggles or safety glasses are essential to protect your eyes from airborne fibers.

- Respiratory Protection: A dust mask or, ideally, an N95 respirator should always be worn to prevent inhalation of fibers. This is a non-negotiable safety precaution.

2. Proper Ventilation

Work in well-ventilated areas. If possible, open windows and doors during installation to allow fresh air circulation and reduce the concentration of airborne fibers.

3. Minimize Disturbance

Handle Glasswool batts or rolls carefully to avoid excessive agitation that releases fibers into the air. Do not shake or tear the material roughly.

4. Clean-Up Procedures

- Do NOT Vacuum with a Household Vacuum: The fine fibers can clog filters and be recirculated into the air.

- Wet Wipe or HEPA Vacuum: Use a damp cloth to wipe surfaces or a vacuum equipped with a HEPA filter.

- Shower and Wash Clothes Separately: After working with Glasswool, shower with cold water first to rinse off fibers without opening pores. Wash work clothes separately from other laundry to avoid cross-contamination.

5. Disposal

Dispose of Glasswool waste in sealed plastic bags to prevent fibers from escaping into the environment or affecting others. Check local regulations for proper waste disposal.

Glasswool in Everyday Living

Once installed and covered by drywall, ceilings, or other finishes, Glasswool insulation poses no significant health risk in a finished building. The fibers are encapsulated and not airborne. The concerns are primarily during the installation or removal process when the material is exposed.

Conclusion: Safe and Effective with Proper Care

Glasswool insulation remains a valuable and effective building material for achieving excellent thermal insulation and acoustic insulation in homes and buildings. While questions about “Is Glasswool safe?” are understandable, current scientific consensus confirms that modern Glasswool is not carcinogenic.

The temporary skin irritation and respiratory discomfort can be entirely managed and prevented by adhering strictly to recommended safety precautions during installation. By wearing appropriate PPE, ensuring good ventilation, and following proper handling and clean-up procedures, you can safely harness the many benefits of this ubiquitous insulation material for your home improvement needs.

FAQ’S

Glasswool insulation is commonly used for thermal insulation, soundproofing, and fire resistance in homes, offices, industrial buildings, HVAC ducts, and metal structures.

Yes. Glasswool is non-combustible and widely used in residential construction. However, during installation, wearing protective gloves, goggles, and a mask is recommended to avoid irritation from loose fibers.

Glasswool has a high R-value, meaning it provides strong thermal resistance. It helps maintain indoor temperature, reduces heat transfer, and can significantly lower cooling and heating costs.

Yes. Glasswool is an excellent acoustic insulation material. Its fibrous structure reduces echo, noise transfer, and vibrations, making it ideal for studios, commercial buildings, and home sound control.