Modern buildings, factories, and commercial projects demand insulation systems that do more than just reduce heat. A combination insulation layer using Rockwool, Aluminium Foil, and XPS delivers thermal resistance, fire safety, moisture control, and long-term energy savings in one integrated solution.

This guide explains how Combination Insulation Layers Rockwool Foil XPS work, where they are used, technical specifications, pricing considerations, and how to choose the right configuration for your project.

What Is a Combination Insulation Layer (Rockwool + Foil + XPS)?

A Combination Insulation Layer is a multi-material insulation system where:

- Rockwool provides fire resistance, acoustic insulation, and high-temperature stability

- Aluminium foil reflects radiant heat and acts as a vapor barrier

- XPS (Extruded Polystyrene) delivers strong thermal insulation with high compressive strength

This layered system is engineered to perform better than any single insulation material used alone.

Why Use Combination Insulation Instead of Single-Layer Systems?

Single insulation materials often solve only one problem. In contrast, Combination Insulation Layers Rockwool Foil XPS address multiple performance requirements simultaneously, especially in harsh climates and industrial environments.

Key Advantages:

- Superior heat reduction

- Fire-rated insulation performance

- Moisture and vapor control

- Structural durability

- Long-term energy efficiency

Layer-by-Layer Breakdown of the System

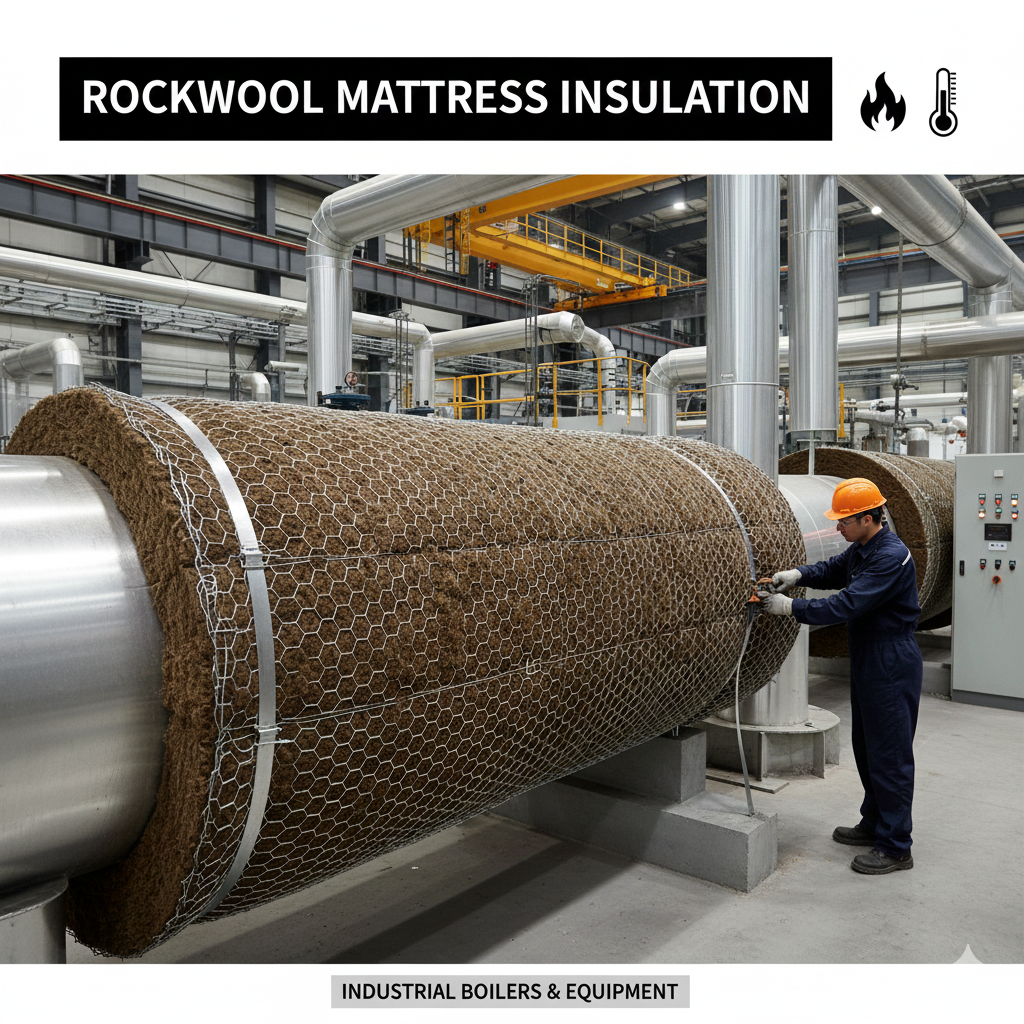

1️⃣ Rockwool Insulation Layer

Rockwool is the backbone of fire and sound protection in the system.

Rockwool density typically ranges between 40–120 kg/m³, depending on application. Higher density improves fire resistance and acoustic performance.

Rockwool insulation specifications commonly include:

- Non-combustible material

- High melting point

- Excellent sound absorption

- Stable performance under extreme heat

For heavy-duty applications, 100mm rockwool insulation is often selected to meet fire-rating and thermal requirements.

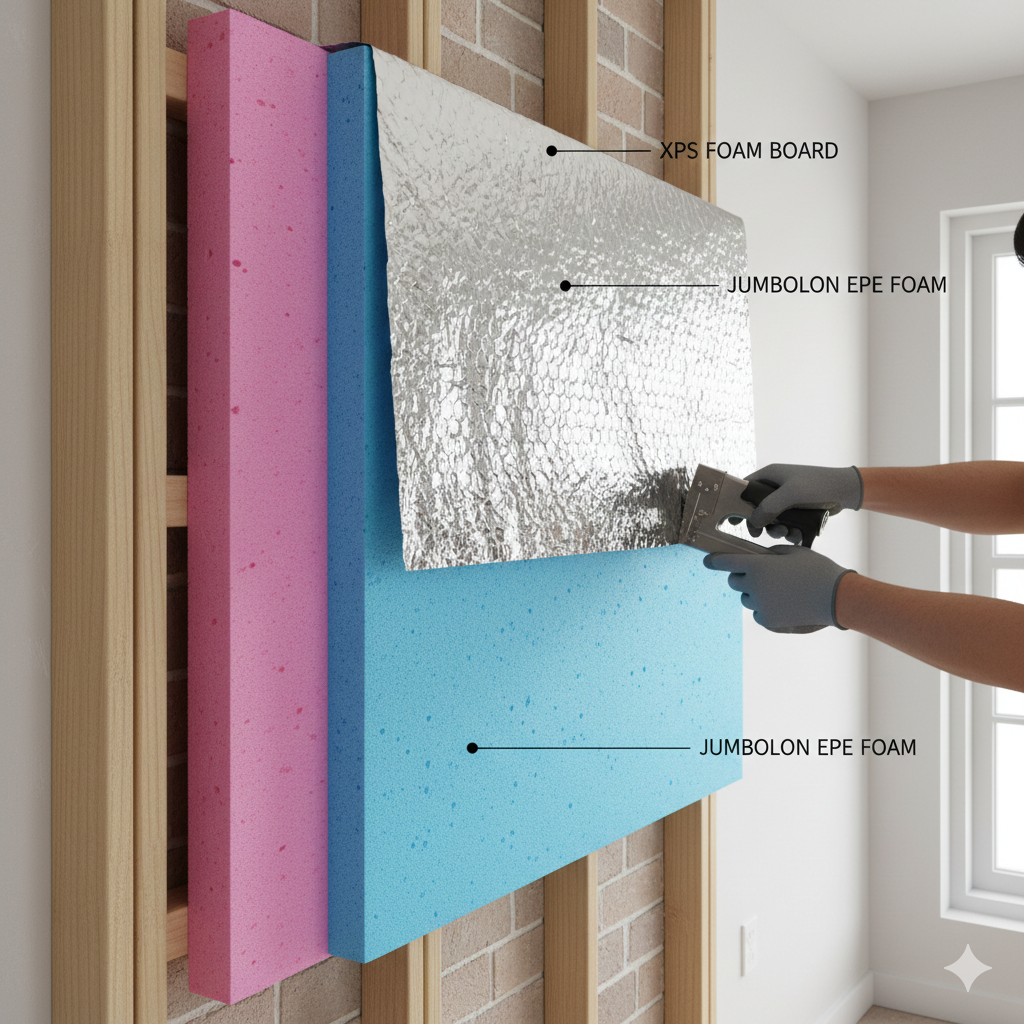

2️⃣ Aluminium Foil Layer

The foil layer plays a critical role in radiant heat reflection.

Functions of aluminium foil:

- Reflects radiant heat back toward the source

- Acts as a vapor barrier

- Prevents moisture penetration

- Improves overall thermal efficiency of the insulation system

Foil placement between layers maximizes thermal resistance and protects inner materials

3️⃣ XPS Insulation Layer

XPS is known for its closed-cell structure, making it ideal for load-bearing and moisture-prone areas.

Key benefits:

- High thermal resistance (R-value)

- Strong compressive strength

- Water resistance

- Long service life

XPS complements rockwool by improving insulation efficiency without adding excessive thickness.

3️⃣ XPS Insulation Layer

XPS is known for its closed-cell structure, making it ideal for load-bearing and moisture-prone areas.

Key benefits:

- High thermal resistance (R-value)

- Strong compressive strength

- Water resistance

- Long service life

XPS complements rockwool by improving insulation efficiency without adding excessive thickness.

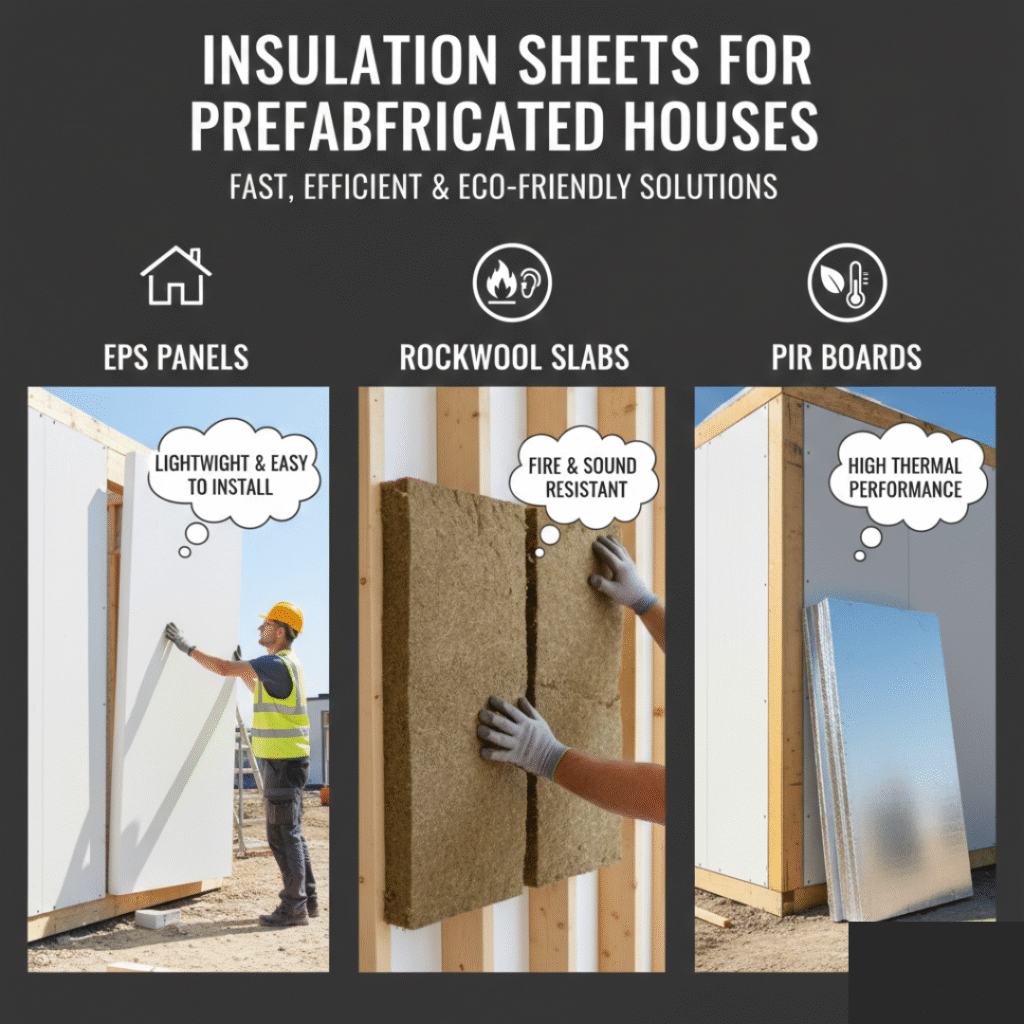

Applications of Rockwool + Foil + XPS Insulation Systems

This combination insulation system is widely used in:

- Industrial factories

- Power plants

- Commercial buildings

- Data centers

- Cold storage facilities

- Roofs and wall insulation systems

- Mechanical rooms and machinery enclosures

It is especially valuable where fire safety, heat control, and durability are non-negotiable.

Combination Insulation Layers Rockwool Foil XPS Price – What Affects Cost?

The Combination Insulation Layers Rockwool Foil XPS price depends on several factors:

- Rockwool density selection

- Thickness (including 100mm rockwool insulation)

- XPS board thickness

- Foil quality and layering method

- Installation complexity

- Project size and location

Higher density rockwool and thicker insulation layers increase cost but significantly improve performance and lifespan.

Technical Performance Overview

| Property | Performance |

|---|---|

| Thermal Resistance | Excellent |

| Fire Resistance | High (Rockwool core) |

| Moisture Control | Very High (Foil + XPS) |

| Acoustic Insulation | Excellent |

| Structural Strength | High |

| Lifespan | Long-term |

How to Choose the Right Configuration

When selecting a combination insulation system, consider:

- Fire rating requirements

- Indoor temperature range

- Moisture exposure

- Structural load

- Energy efficiency goals

Projects with strict fire regulations often prioritize higher rockwool density, while energy-focused projects may increase XPS thickness.

Installation Best Practices

Proper installation is critical for system performance:

- Ensure tight joints between insulation layers

- Place foil with reflective side facing heat source

- Avoid compression of rockwool beyond specifications

- Seal all gaps to prevent thermal bridging

Professional installation ensures the system performs as designed.

Long-Term Benefits of Combination Insulation Systems

- Reduced energy bills

- Improved fire safety compliance

- Lower HVAC load

- Enhanced indoor comfort

- Reduced maintenance costs

- Increased building lifespan

Is This Insulation System Worth the Investment?

For projects requiring maximum thermal efficiency and fire safety, the answer is yes. While the initial Combination Insulation Layers Rockwool Foil XPS price may be higher than single-layer insulation, the long-term savings and safety benefits justify the investment.

Conclusion

A Combination Insulation Layer using Rockwool, Aluminium Foil, and XPS is a future-ready solution for modern buildings and industrial facilities. By combining fire resistance, thermal insulation, and moisture control, this system delivers unmatched performance in demanding environments.

FAQ’S

For most commercial and industrial projects, 100mm rockwool insulation combined with 25–50mm XPS delivers optimal fire resistance and thermal performance. Thickness may vary based on fire-rating and energy-efficiency requirements.

Higher rockwool density improves fire resistance, sound absorption, and durability. Medium to high-density rockwool is recommended when used in combination insulation layers with foil and XPS.

Yes. Aluminium foil significantly improves performance by reflecting radiant heat and acting as a vapor barrier, which enhances the overall efficiency of Rockwool insulation specifications.

Pricing depends on rockwool density, thickness (including 100mm rockwool insulation), XPS board thickness, foil quality, installation method, and project scale. Industrial-grade systems cost more but offer longer service life.

These systems are widely used in factories, commercial buildings, power plants, mechanical rooms, roofs, and walls where fire safety and thermal control are critical.

Yes. Combination insulation layers outperform single materials by providing fire resistance, thermal insulation, moisture control, and acoustic performance in one integrated system.