In modern construction, energy efficiency is no longer optional—it’s essential. One of the most effective ways to reduce energy consumption and utility costs is by investing in proper insulation. Whether for residential or commercial buildings, proper insulation ensures that your indoor environment remains comfortable while minimizing energy waste.

What Is Proper Insulation?

Proper insulation refers to materials and techniques used to prevent heat loss in winter and heat gain in summer. It acts as a barrier to reduce the exchange of energy between indoor and outdoor environments. Proper insulation can be applied in walls, roofs, attics, and lofts to maximize thermal comfort.

Key areas include:

- Roof insulation – The primary barrier against heat entering from above.

- Attic insulation – Ensures stored heat or cool air is maintained.

- Loft insulation – Prevents energy loss through uninsulated roof spaces.

Technical Comparison Table – Roof/Attic Insulation Options

| Insulation Material | R-Value / Thermal Resistance | Water Resistance | Sound Absorption | Lifespan (Years) | Typical Price Range (PKR/m²) |

|---|---|---|---|---|---|

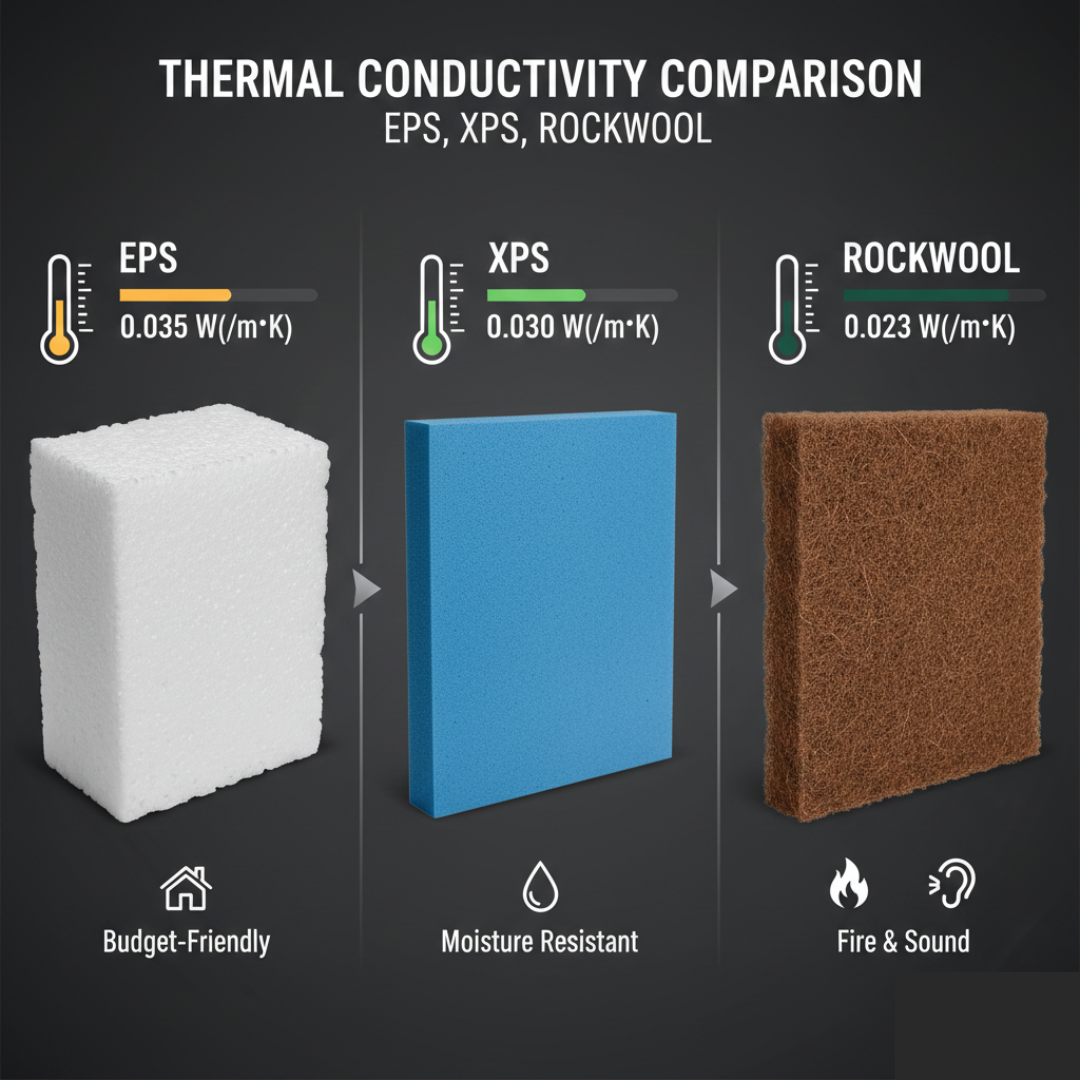

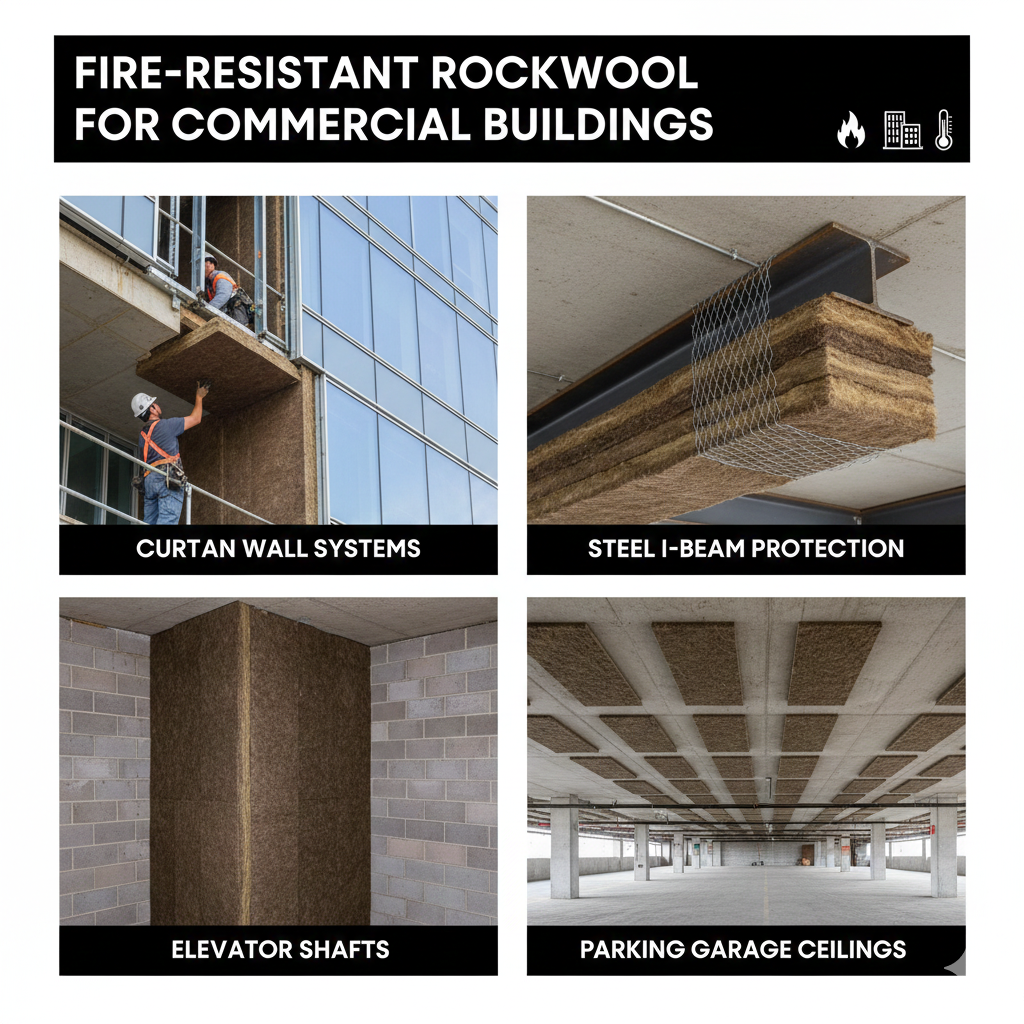

| Rockwool | High | Moderate | Excellent | 20–30 | 700–1,200 |

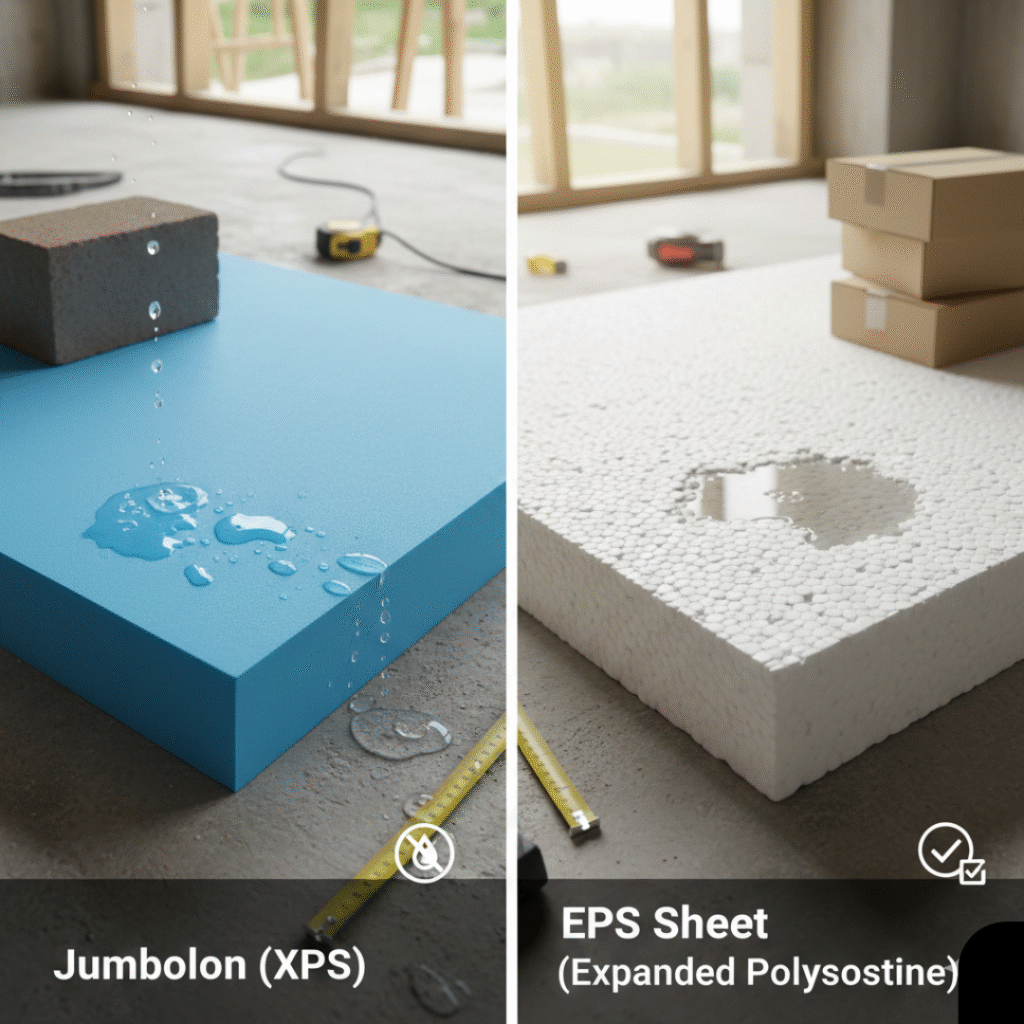

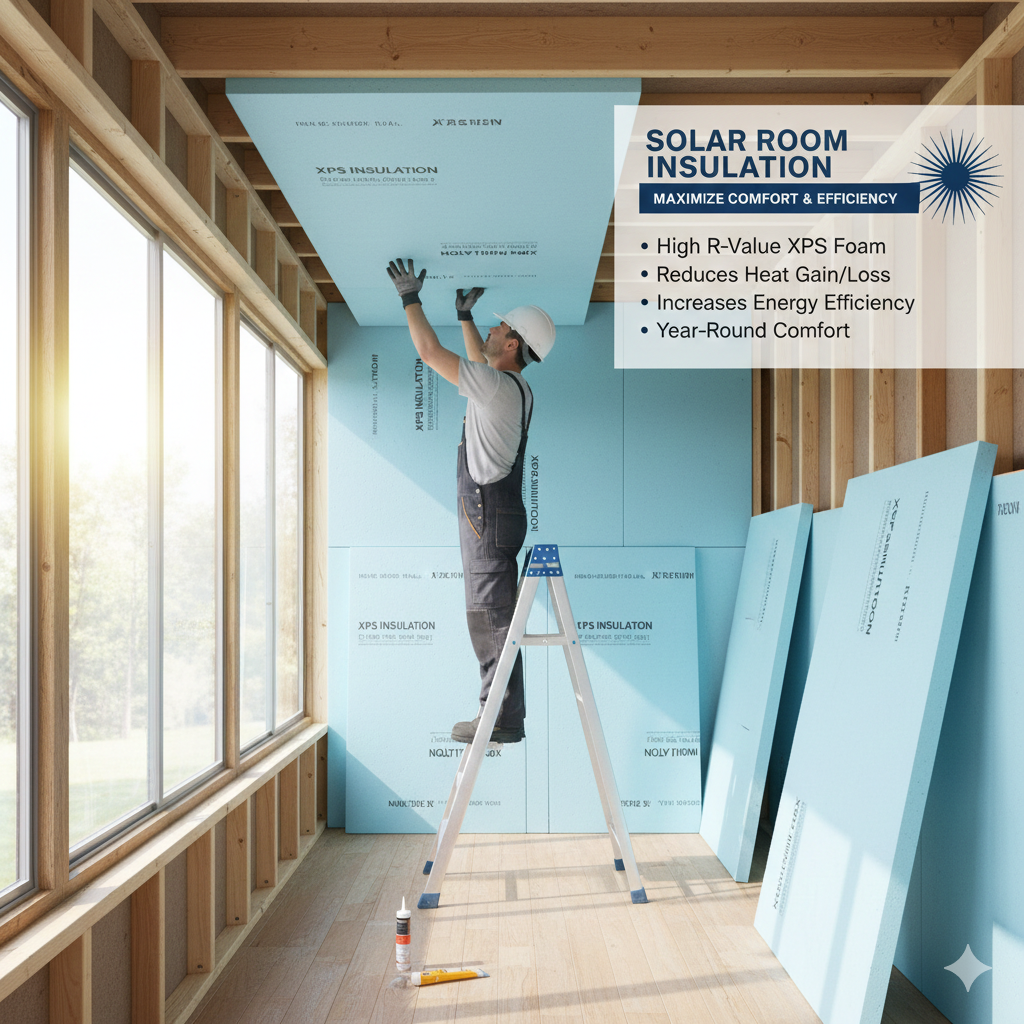

| XPS Boards | High | Excellent | Good | 25–30 | 600–1,000 |

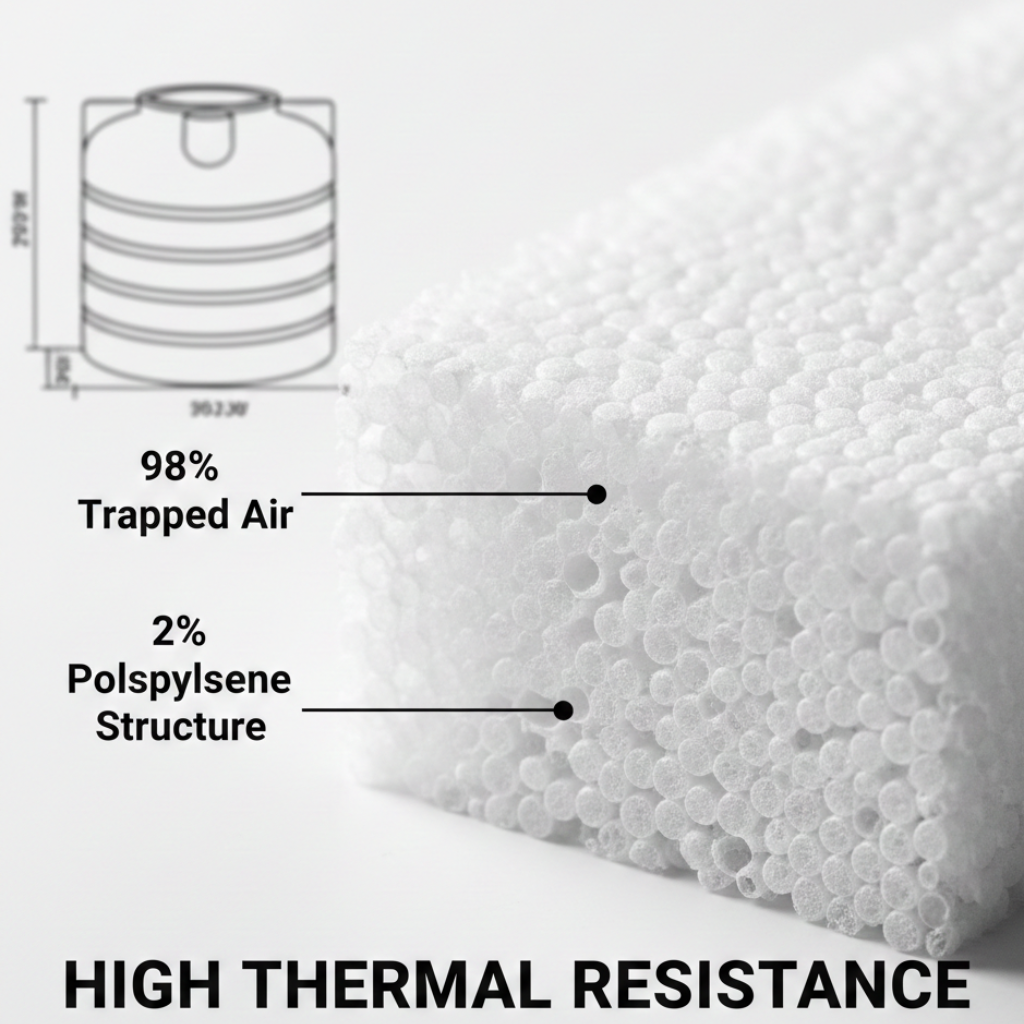

| EPS Sheets | Medium | Good | Fair | 15–20 | 500–900 |

| Reflective Aluminium Foil | Medium (reflective heat) | Excellent | Minimal | 10–15 | 400–800 |

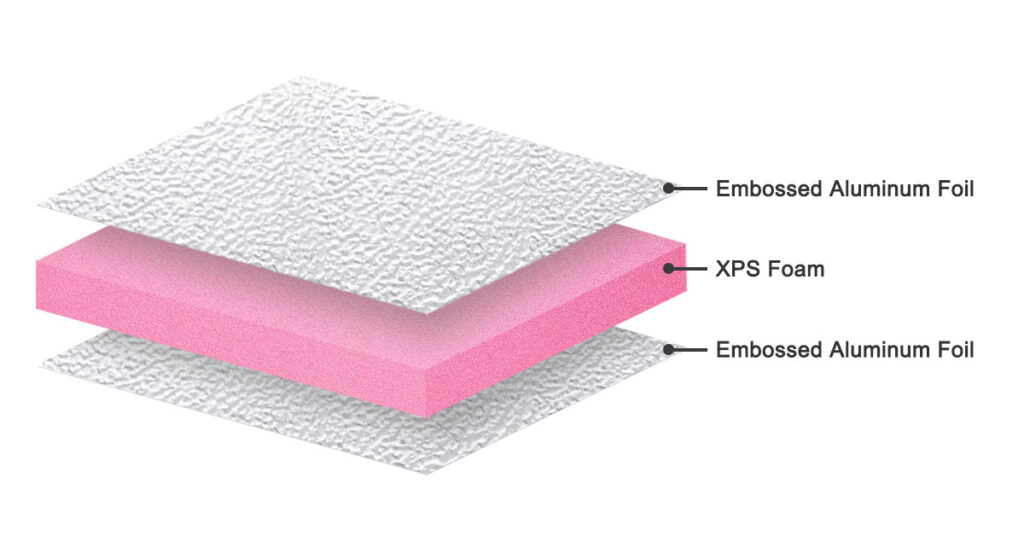

| Combination (Foil + XPS) | Very High | Excellent | Good | 25–30 | 900–1,400 |

Note: Prices and performance may vary depending on thickness, density, and local suppliers.

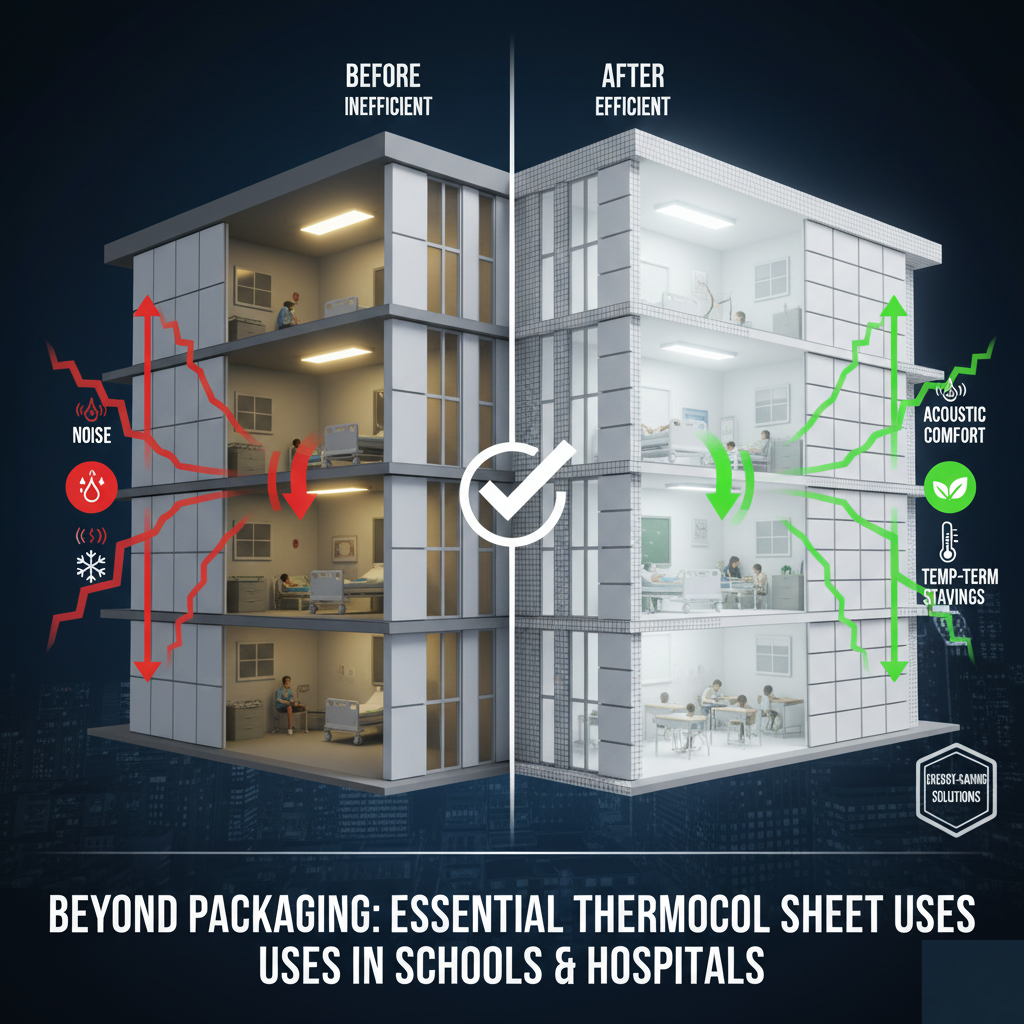

How Proper Roof Insulation Improves Energy Efficiency

Proper roof insulation is one of the most impactful investments for energy efficiency. Roofs are responsible for up to 30% of energy loss in buildings. By installing quality insulation:

- Reduce your heating and cooling cost by maintaining a stable indoor temperature.

- Improve building comfort during summer and winter months.

- Proper insulation generally lowers electricity bills by decreasing the load on HVAC systems.

- Protect roofing materials by reducing thermal stress and condensation.

Ways to Improve Insulation in Your Building

Improving insulation in your building doesn’t always require a full renovation. Here are effective strategies:

- Insulate Your Loft: Adding loft insulation is cost-effective and prevents heat loss through the roof.

- Insulate Your Attic: For buildings with unoccupied attic spaces, insulating the attic floor can reduce energy waste.

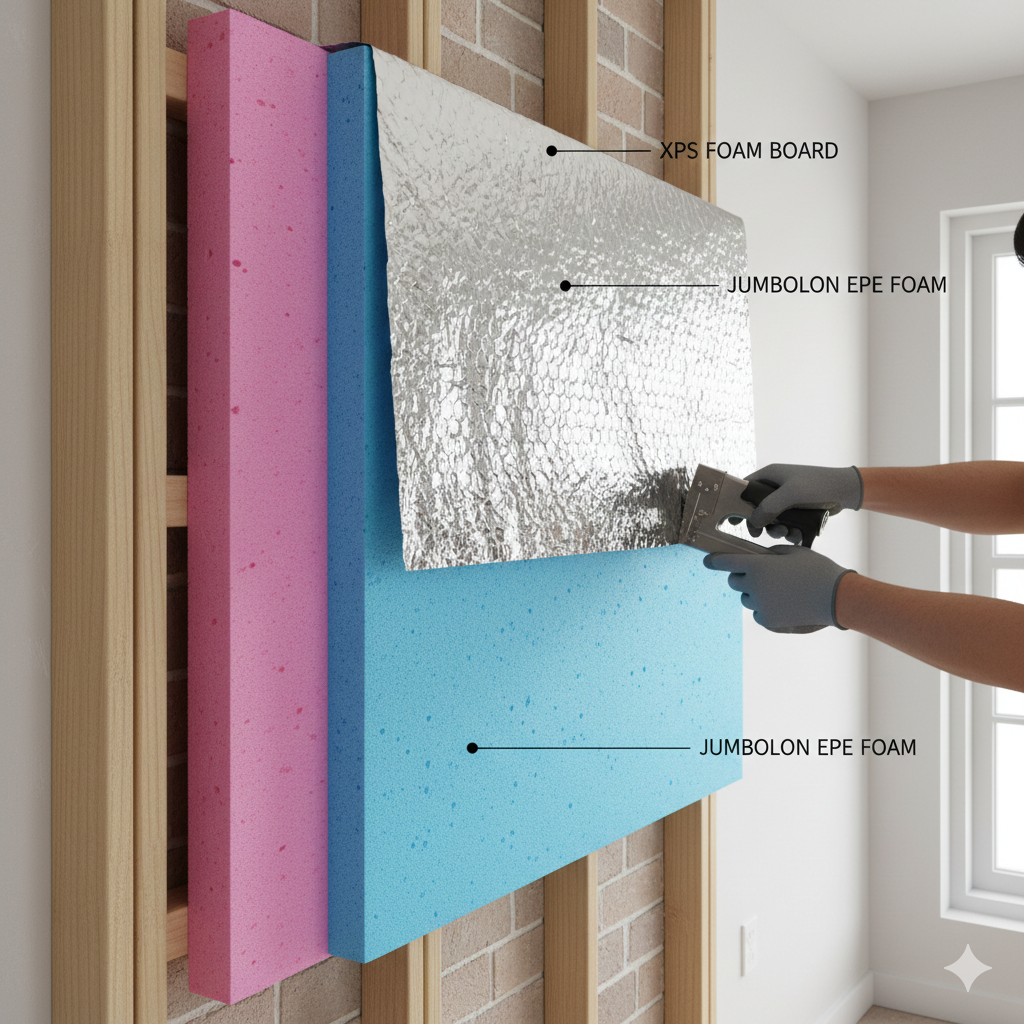

- Upgrade Roof Insulation Materials: Using reflective foil, XPS, EPS, or Rockwool insulation layers can significantly improve thermal performance.

- Seal Gaps and Leaks: Proper sealing of vents, ducts, and chimneys complements insulation and reduces drafts.

Implementing these steps can deliver a noticeable energy efficiency boost with proper insulation and significantly reduce your electricity bills.

Benefits of Proper Insulation

- Energy Savings: Lower energy bills through efficient thermal management.

- Enhanced Comfort: Stable indoor temperatures throughout the year.

- Environmental Impact: Reduced carbon footprint by using less electricity.

- Property Value: Energy-efficient buildings are more attractive to buyers and tenants.

- Durability: Protects roofing and interior structures from condensation and moisture damage.

Choosing the Right Insulation Material

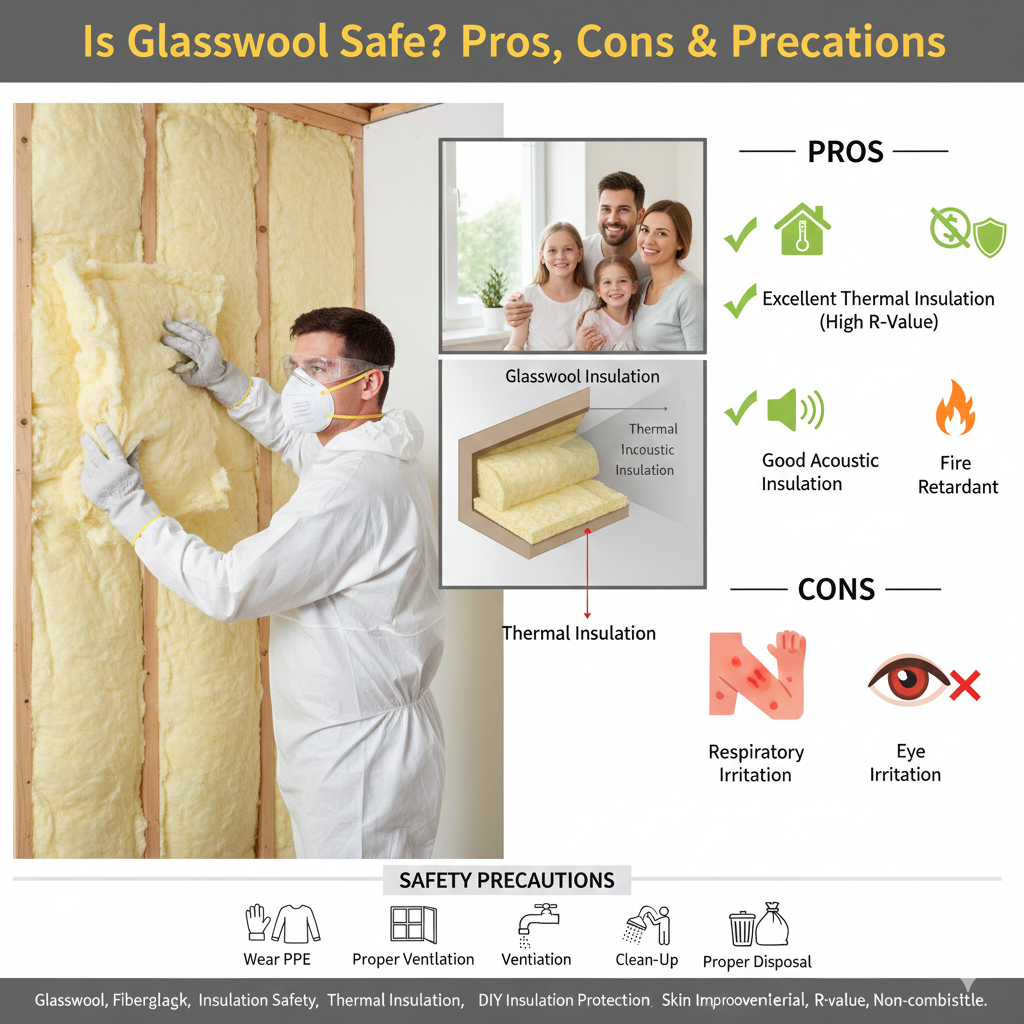

Selecting the right insulation material depends on your building type, climate, and budget. Common options include:

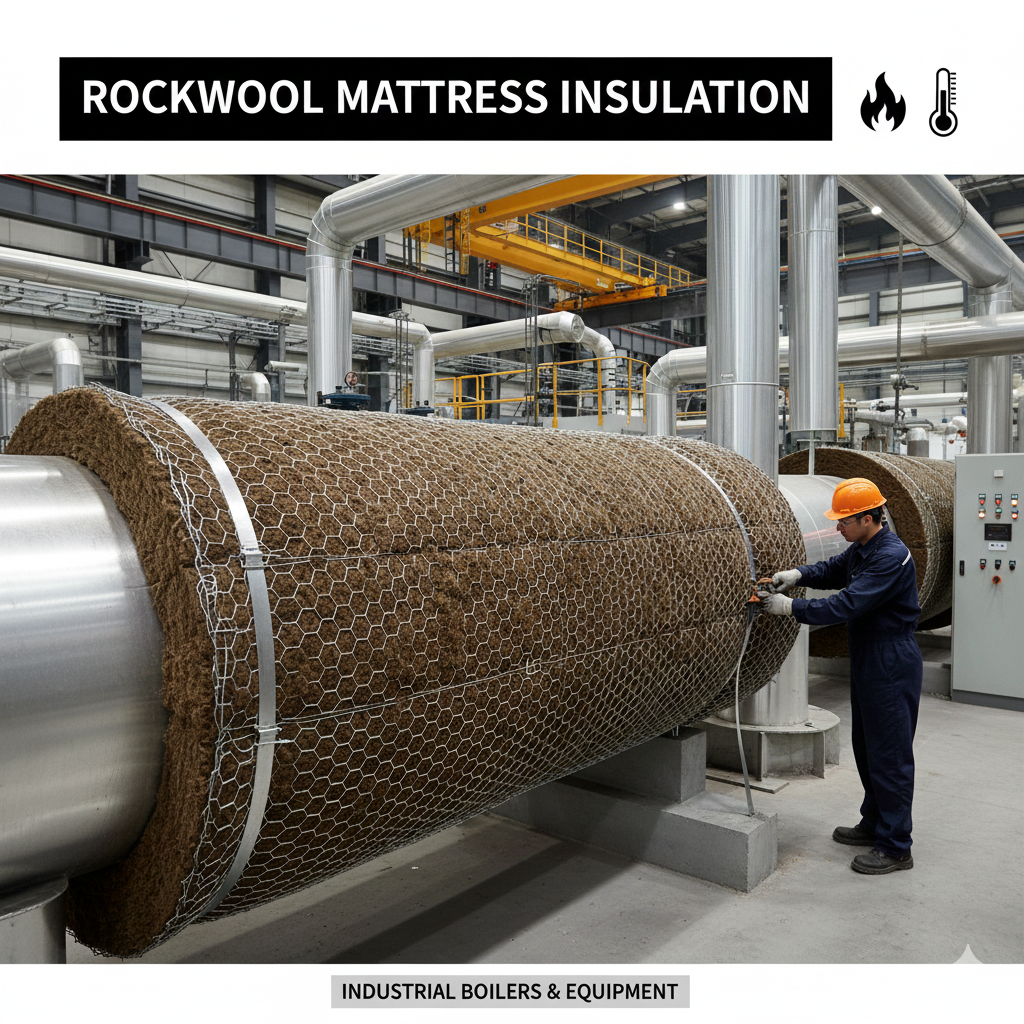

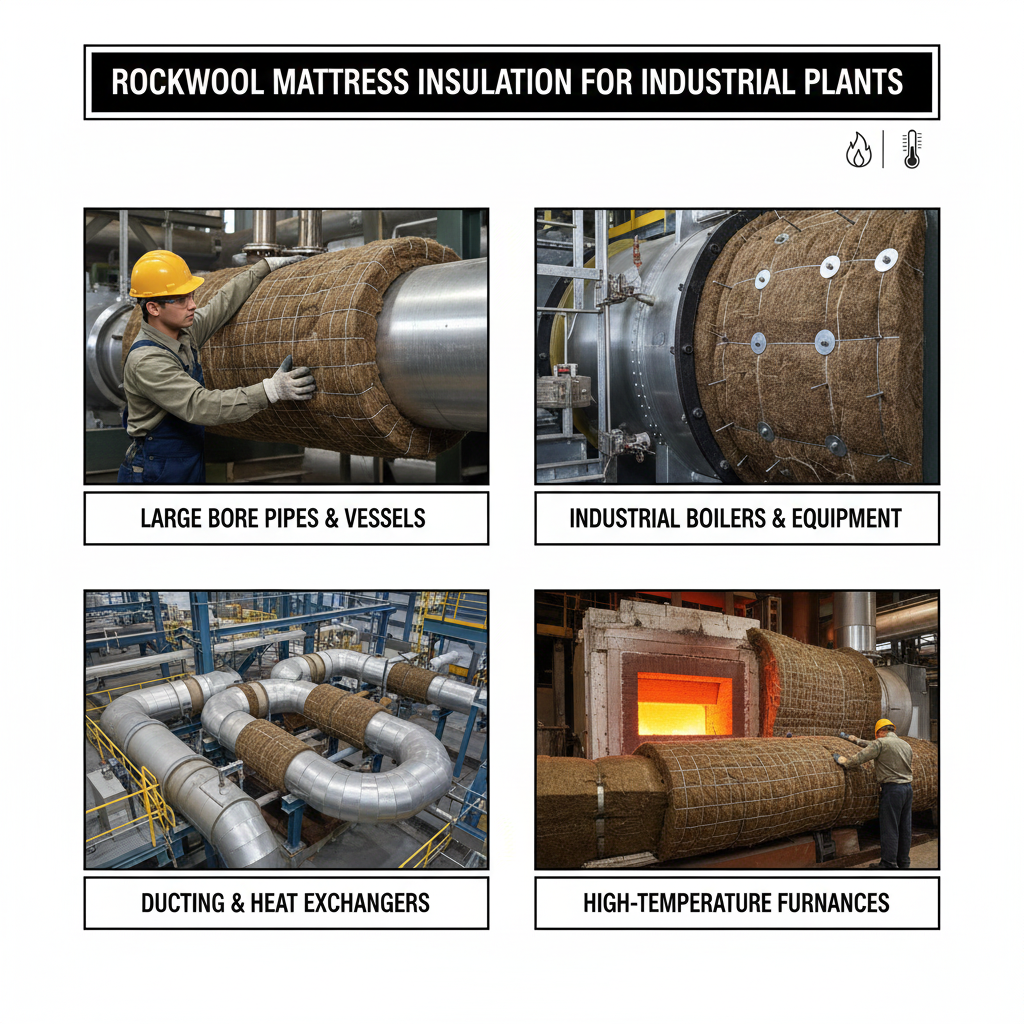

- Rockwool Insulation: Fireproof, sound-absorbing, and high thermal resistance.

- EPS & XPS Boards: Lightweight, water-resistant, and high insulation efficiency.

- Reflective Aluminium Foil: Excellent for reflective heat reduction in attics and lofts.

By combining materials, such as foil with XPS or Rockwool, you can maximize performance for both heat and sound insulation.

Energy Efficiency Boost with Proper Insulation Price Considerations

The energy efficiency boost with proper insulation price varies depending on the material, thickness, and installation complexity. Factors include:

- Type of insulation (Rockwool, XPS, EPS, reflective foil).

- Area to be insulated (attic, loft, roof, walls).

- Labor and installation techniques.

Investing in high-quality insulation may cost more initially but yields long-term savings on electricity bills and enhances building comfort.

FAQ’S

The energy efficiency boost with proper insulation price depends on the material used, area covered, and installation type. On average, roof or attic insulation can save 20–30% on energy bills, making the investment worthwhile.

Both are effective, but if the attic is unoccupied, insulating the attic floor prevents heat loss. Loft insulation is more suitable when the loft space is used regularly.

Yes, proper roof insulation minimizes heat exchange, reducing reliance on AC or heating systems, which immediately lowers electricity usage.

Materials like Rockwool, XPS boards, and reflective aluminium foils are highly effective. For extreme climates, a combination of foil with XPS or Rockwool provides maximum heat resistance and comfort.

Absolutely. Upgrading insulation in older buildings can drastically improve indoor comfort, reduce energy bills, and increase property value.

High-quality insulation materials, such as Rockwool or XPS, can last 20–30 years when installed correctly, providing long-term energy savings.