Maintaining precise, low temperatures is paramount for cold storage facilities and refrigeration units. Any inefficiency in insulation can lead to significant energy waste, temperature fluctuations that compromise stored goods, and the costly formation of ice and condensation. This is where Jumbolon insulation, a high-performance Extruded Polystyrene (XPS) foam, emerges as an indispensable material.

Jumbolon’s unique properties make it exceptionally well-suited for the demanding environments of cold room panels, walk-in freezers, and industrial refrigeration. It delivers the robust thermal protection and moisture resistance essential for preventing heat gain and ensuring optimal operational efficiency.

The Critical Demands of Cold Environments

Cold storage applications face unique challenges that standard insulation materials often fail to address adequately:

1. Extreme Temperature Differential

The vast difference between the internal cold temperature and the external ambient temperature creates a constant drive for heat to infiltrate the unit. This requires an insulation material with a very high R-value and exceptional thermal resistance.

2. Vapor Drive and Condensation

Warm, humid air from outside constantly tries to migrate into the cold space. If this vapor isn’t stopped effectively, it will condense and freeze, leading to ice formation, structural damage, reduced efficiency, and potential mold growth. An effective vapor barrier is critical.

3. Hygienic Requirements

Cold storage units must maintain strict hygiene standards to protect perishable goods. Insulation materials that absorb moisture or foster mold are unacceptable.

Jumbolon’s Unmatched Advantages for Cold Storage

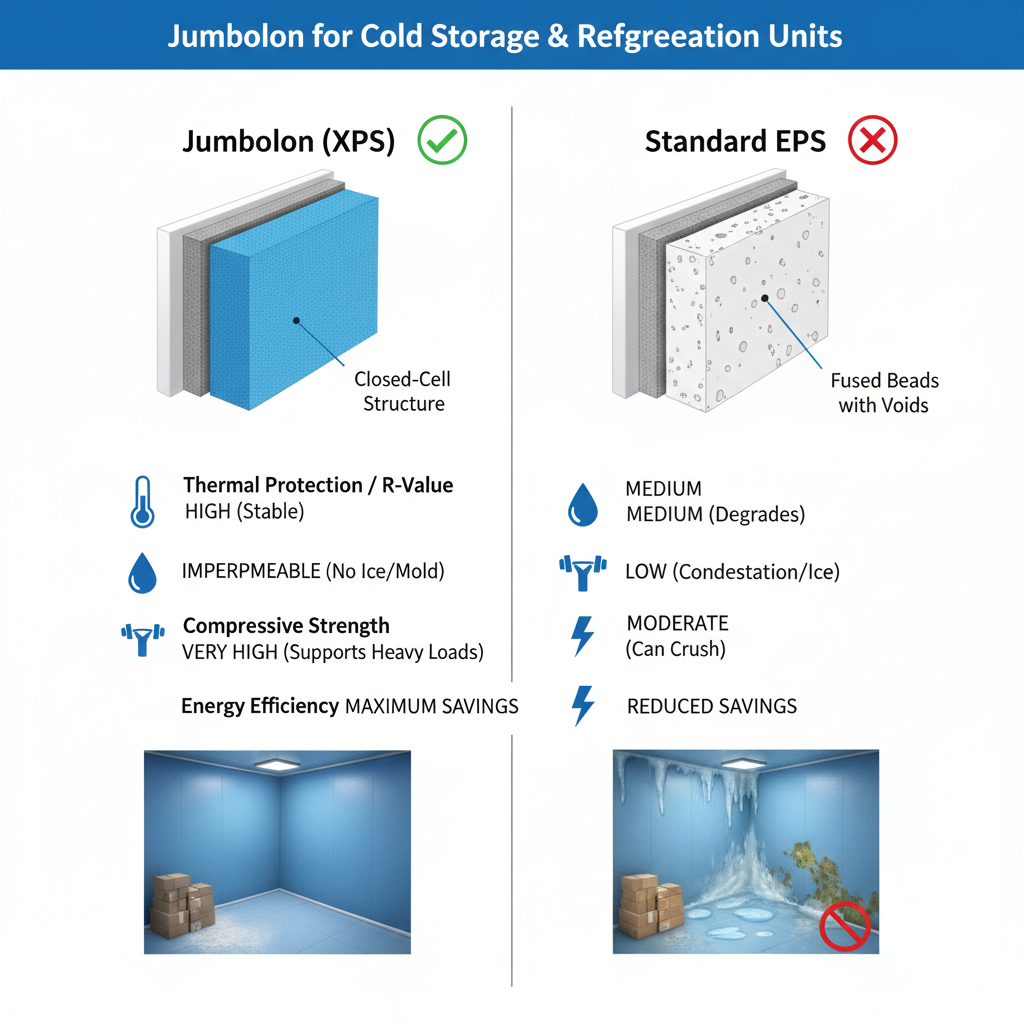

Jumbolon (XPS) offers a suite of properties that directly address these challenges, making it an ideal choice for cold storage insulation.

1. Superior Thermal Performance (High R-Value)

Jumbolon boasts a high R-value per inch (typically R-5.0), providing excellent thermal protection in critical temperature-controlled environments. Its consistent insulation value minimizes heat transfer, significantly reducing the energy load on refrigeration systems. This translates directly to enhanced energy efficiency and lower operating costs for any refrigeration unit.

2. Unrivaled Moisture Resistance

The defining feature of Jumbolon is its completely closed-cell structure. This makes it virtually impervious to water absorption and water vapor transmission. In cold room applications, this means: * No Ice Formation: Jumbolon prevents the infiltration of moisture that would otherwise freeze within the insulation or on surfaces. * Maintained R-Value: Unlike materials that lose insulating power when wet, Jumbolon’s R-value remains stable, ensuring consistent long-lasting insulation. * Vapor Barrier: It acts as an inherent vapor barrier, mitigating condensation and mold growth.

3. High Compressive Strength

Cold room panels and flooring often bear heavy loads from stored goods, shelving, and forklift traffic. Jumbolon’s high compressive strength allows it to withstand these pressures without deforming, ensuring the long-term integrity of the insulated structure and preventing thermal bridging caused by crushing. This makes it ideal for floor insulation in freezers.

4. Durability and Longevity

The robust nature of Jumbolon ensures it stands up to the harsh conditions of cold storage environments. Its resistance to rot, decay, and insect infestation, combined with its stable thermal performance, means it provides long-lasting insulation requiring minimal maintenance.

Applications in Cold Storage & Refrigeration

Jumbolon is versatile enough for various components within cold environments:

- Cold Room Panels: Used as the core insulating material in pre-fabricated or custom-built panels.

- Floor Insulation: Critical for preventing frost heave and maintaining floor temperature in walk-in freezers and coolers. Its compressive strength is essential here.

- Wall and Ceiling Insulation: Forms a continuous thermal envelope to minimize heat leakage throughout the structure.

- Refrigerated Transport: Increasingly used in the construction of refrigerated containers and trucks for its lightweight and superior insulation properties.

The Economic and Operational Benefits

Investing in Jumbolon for your cold storage or refrigeration unit offers clear advantages:

- Significant Energy Savings: The superior thermal resistance and air sealing properties drastically reduce the energy consumption of refrigeration systems.

- Product Integrity: Stable temperatures and absence of moisture protect sensitive goods (food, pharmaceuticals, chemicals) from spoilage or damage.

- Reduced Maintenance: Prevents issues like ice formation, rust, and mold growth, leading to lower repair and cleaning costs.

- Optimized Space: Its high R-value allows for thinner insulation profiles compared to less efficient materials, maximizing usable interior space.

For any application where precise temperature control and moisture resistance are non-negotiable, Jumbolon insulation offers a reliable, efficient, and long-lasting insulation solution, solidifying its position as the preferred choice for cold storage insulation.

FAQ’S

Jumbolon (XPS) is highly recommended for cold storage because it has excellent thermal resistance, low water absorption, and high compressive strength. These properties help maintain stable low temperatures, reduce energy consumption, and prevent moisture buildup inside refrigeration units.

For standard cold rooms, 50mm to 75mm Jumbolon sheets are commonly used, while freezer rooms and deep-freeze units often require 100mm or higher thickness. The ideal thickness depends on temperature requirements, insulation design, and building specifications.

Yes. Jumbolon’s closed-cell structure makes it moisture-resistant, preventing condensation, mold, and water absorption. This is essential for maintaining hygiene standards in cold storage and refrigerated warehouse environments.

Absolutely. Jumbolon is used for walls, roofs, floors, and doors of cold storage units due to its high durability and thermal efficiency. It provides long-lasting performance even under constant low-temperature conditions.