Introduction

In the world of construction and home improvement, insulation is not merely an option—it’s a critical component for energy efficiency, comfort, and safety. Among the numerous insulation material options available, Rockwool insulation sheet (also commonly known as stone wool or mineral wool) stands out as a high-performance solution.

But what exactly is it? Unlike traditional fiberglass or foam, Rockwool is an innovative product created from molten volcanic rock and slag, spun into fine fibers, and compressed into rigid or semi-rigid sheets. This unique manufacturing process gives it a powerful trifecta of benefits: exceptional thermal performance, superior acoustic insulation, and incredible fire resistance.

If you’re looking to upgrade your building’s envelope, save on energy bills, or enhance your interior comfort, understanding the properties of this fascinating insulation material is your first step.

What is Rockwool Insulation?

The foundation of Rockwool is literally rock. The process involves heating basalt rock and recycled slag (a by-product of the steel industry) to over $1500^{\circ}C$ until they melt. This lava-like material is then poured into rapidly spinning wheels, which sling the molten substance outward, transforming it into millions of thin, interweaving fibers—much like making cotton candy. A binder is added, and the fibers are compressed and cured into the final product: the Rockwool insulation sheet.

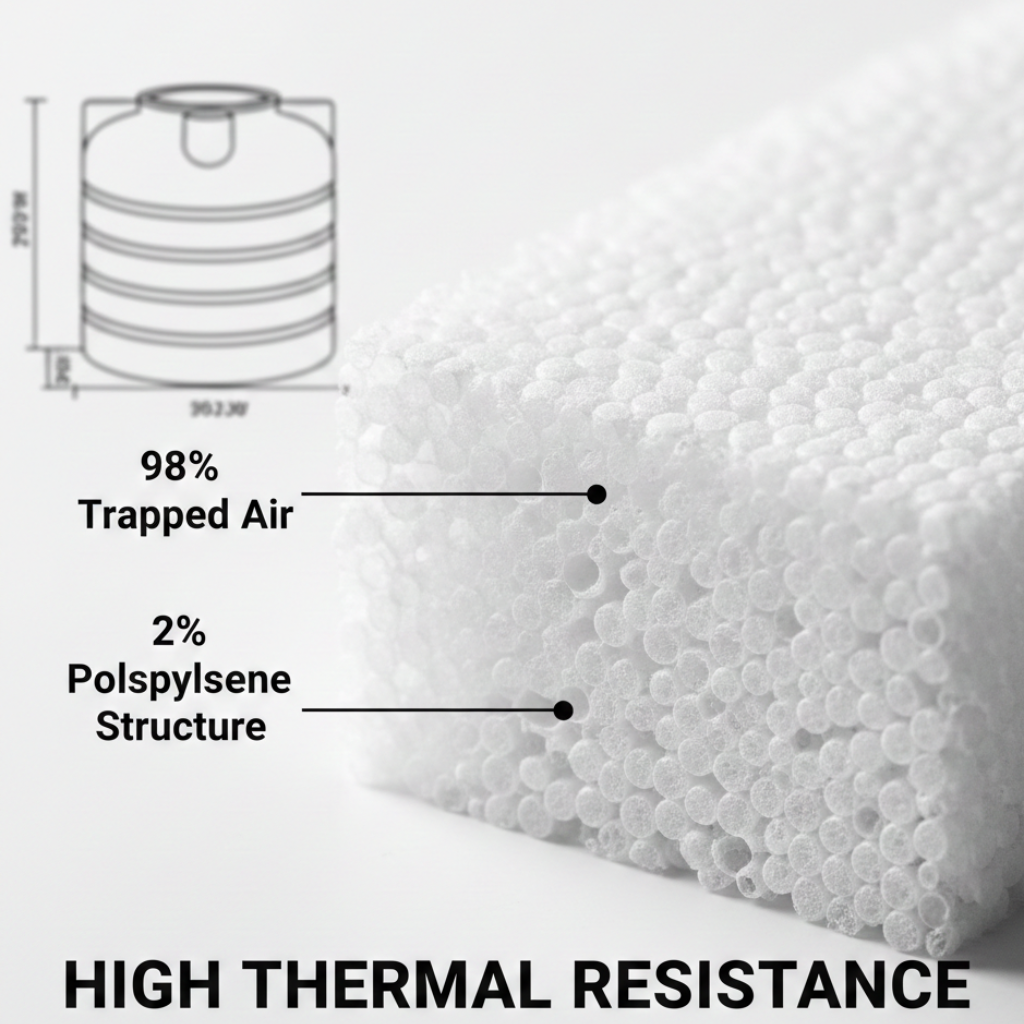

This dense, non-directional fiber structure is key to its outstanding performance, creating millions of tiny air pockets that trap heat and dissipate sound waves.

The Unmatched Benefits of Rockwool

Choosing the right insulation material is crucial, and Rockwool offers compelling advantages over traditional DIY insulation choices:

1. Superior Thermal Performance (R-Value)

Rockwool boasts an excellent thermal performance thanks to its high density. It efficiently maintains its structural integrity over time, meaning its R-value (a measure of resistance to heat flow) remains consistent. This translates directly into lower heating and cooling costs, making it a sustainable choice for long-term energy savings.

2. Exceptional Fire Protection

Perhaps the most impressive benefit is its inherent fire safety. Because it is made from stone, Rockwool insulation sheet is non-combustible. It can withstand temperatures exceeding $1000^{\circ}C$ without melting, offering a critical barrier that can significantly slow the spread of fire and provide occupants with valuable time to evacuate.

3. High-Grade Acoustic Insulation

For projects where noise reduction is a priority—such as soundproofing a home office, basement studio, or apartment wall—Rockwool excels. Its dense, fibrous structure absorbs sound vibrations, providing superior acoustic insulation compared to many other materials. It helps minimize both airborne sound (voices, music) and impact noise (footsteps).

4. Moisture Resistance

While it is breathable, Rockwool is also resistant to water absorption, meaning it will not hold water and lose its insulating properties if exposed to moisture. This characteristic helps prevent mold and mildew growth, contributing to better indoor air quality.

Common Applications of Rockwool Insulation

The versatility of the Rockwool insulation sheet makes it suitable for a wide range of building envelope and home improvement projects:

- Wall Cavities: Used in both interior and exterior walls for thermal and acoustic control.

- Attics and Ceilings: Especially effective in high-heat areas to maintain a consistent temperature.

- Floors: Provides sound dampening between floors in multi-story buildings.

- HVAC Ductwork: Applied to the outside of heating and cooling ducts to improve efficiency and reduce mechanical noise.

- Basement and Crawlspaces: Helps manage moisture and maintain thermal control in below-grade areas.

Key Considerations for Installation

While DIY insulation with Rockwool is feasible, a few tips can ensure a perfect, high-performance fit:

- Safety First: Always wear long sleeves, gloves, and a dust mask. While Rockwool fibers are not as itchy as fiberglass, proper protection is essential.

- Precise Cutting: Use a long, sharp utility knife to cut the sheets. Measure the cavity width carefully and cut the batts about half an inch wider. This slight oversizing ensures a friction fit, eliminating gaps that compromise thermal performance.

- Friction Fit: The goal is a snug, perfect friction fit. There should be no compressing, bending, or squeezing of the insulation material—simply place it gently into the stud cavity.

- Vapor Barrier: In colder climates, or where required by building codes, ensure you install a continuous polyethylene vapor barrier on the warm-in-winter side of the wall assembly to manage condensation.

Rockwool vs. Fiberglass: Which is Better?

When comparing insulation material for your next project, fiberglass is often the main competitor. Here is a brief comparison:

| Feature | Rockwool (Mineral Wool) | Fiberglass |

| Primary Material | Volcanic rock, slag | Sand, recycled glass |

| R-value per Inch | Generally higher (superior thermal performance) | Generally lower |

| Fire Resistance | Excellent (Non-combustible) | Can melt at high temperatures |

| Acoustic Insulation | Excellent (High density) | Good (Lower density) |

| Moisture Resistance | Very good | Fair (Can lose R-value when wet) |

For projects requiring the highest levels of fire safety and acoustic insulation, the Rockwool insulation sheet is the preferred choice. For basic thermal control on a tight budget, fiberglass may be considered.

Rockwool Sheet Application in Exterior Insulation Systems

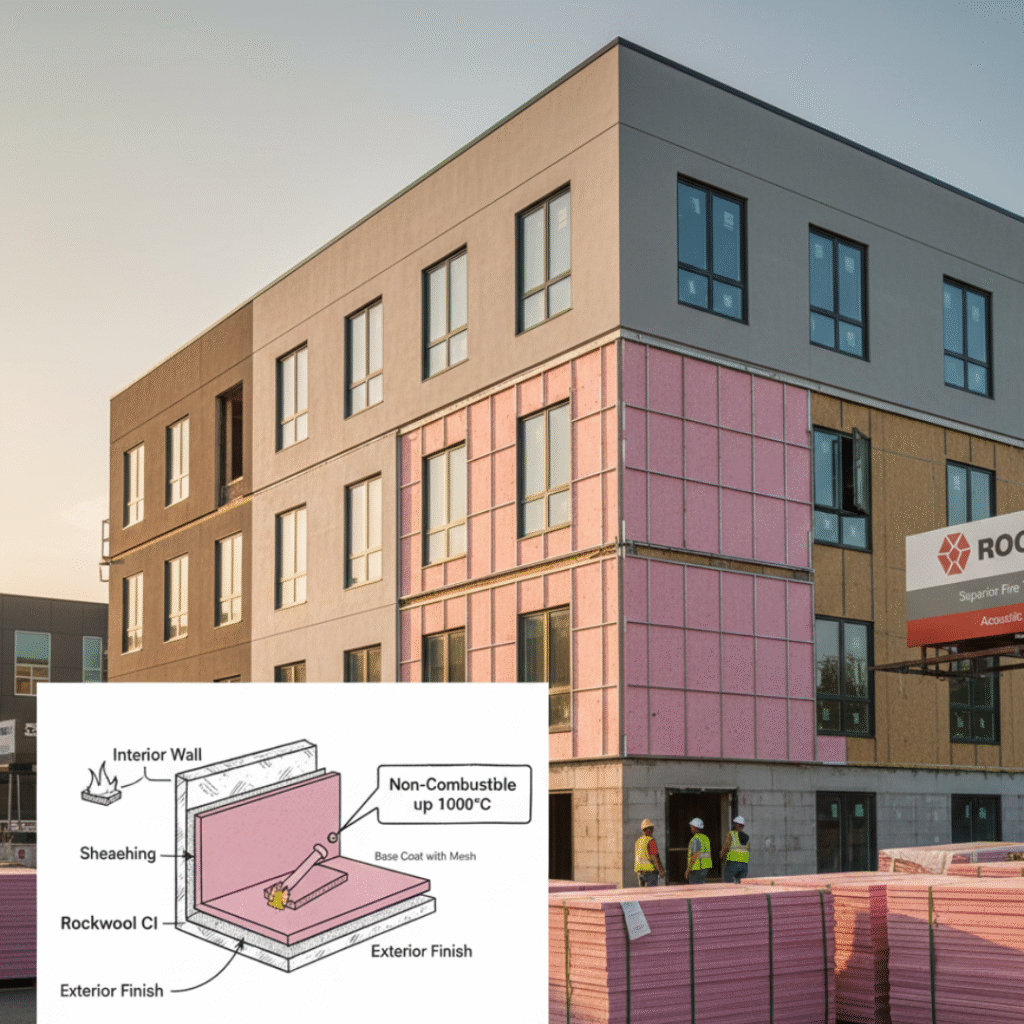

While Rockwool is often celebrated for its use in interior walls and ceilings, its unique properties—especially its density, moisture repellency, and non-combustibility—make it an exceptional insulation material for exterior systems, particularly in large commercial and high-rise buildings where safety codes are stringent.

Using a Rockwool insulation sheet on the exterior is a form of continuous insulation (CI), which wraps the building in a thermal blanket, drastically improving thermal performance by eliminating thermal bridging through wall studs.

1. Exterior Insulation and Finish Systems (EIFS)

EIFS refers to non-load bearing building cladding systems that provide exterior walls with an insulated, water-resistant, finished surface.

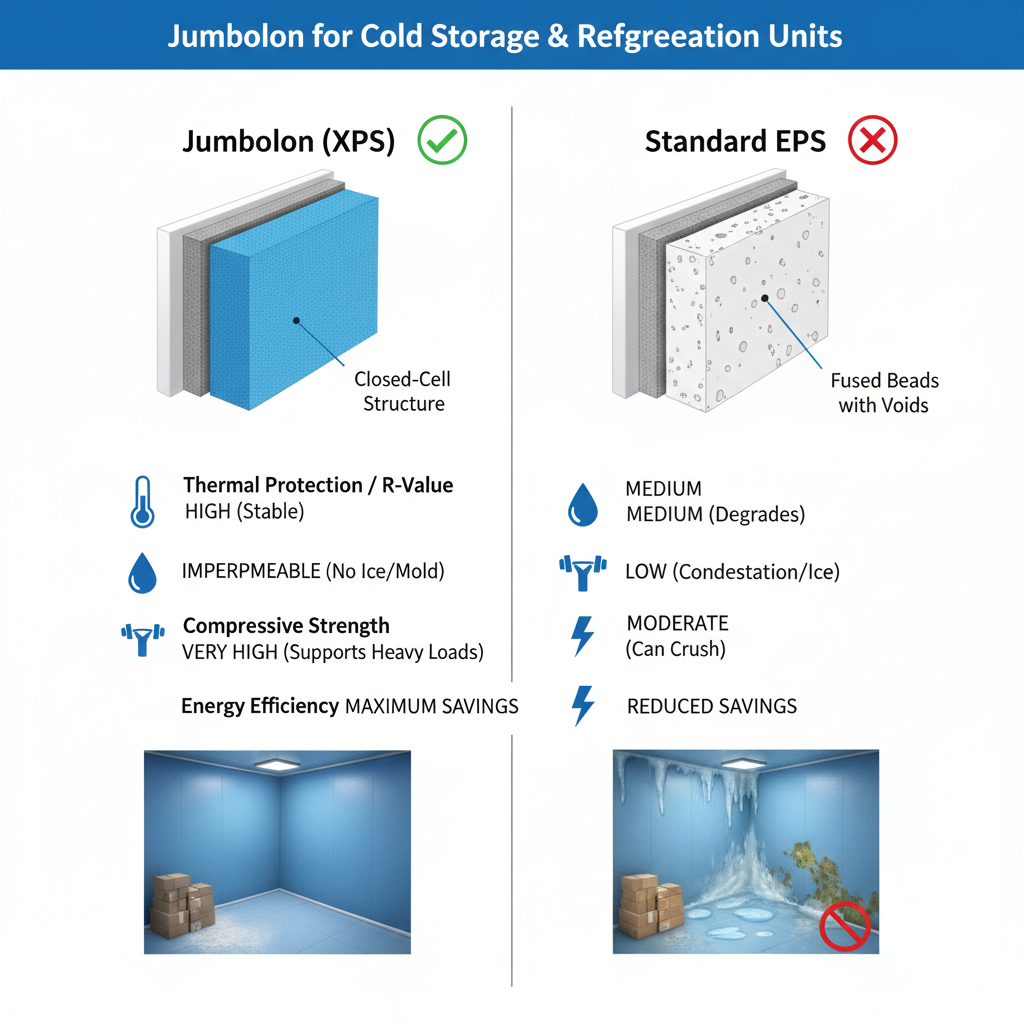

- Traditional EIFS: Historically, EIFS used foam plastics (like EPS or XPS). However, due to concerns over the combustibility of these materials, especially in mid-to-high-rise construction, Rockwool (mineral wool) has become the preferred choice for a non-combustible substrate.

- The Rockwool Advantage in EIFS: Rigid stone wool boards (e.g., specific high-density Rockwool products) are mechanically fastened or adhered to the exterior sheathing. This layer provides the superior fire resistance of rock while acting as a stable, dimensionally sound base for the subsequent layers (base coat, mesh, and decorative render/finish). This combination offers the highest possible fire rating (A1/Class A non-combustible).

2. Rainscreen and Cavity Wall Systems

Rainscreen and cavity wall systems are modern façade designs that create an intentional air gap (cavity) between the insulation and the exterior cladding (e.g., metal panels, brick, or siding). This gap manages moisture by allowing water that penetrates the cladding to drain away.

- Cavityrock Insulation: Rockwool manufactures specialized semi-rigid boards designed specifically for this application. These boards are installed in the cavity, right against the exterior wall sheathing.

- Superior Moisture Management: The stone wool boards are water repellent yet vapor permeable. This means they actively shed liquid water that might trickle down the cavity while allowing water vapor from inside the wall assembly to pass through and dry out. This breathability is crucial for preventing condensation, mold, and rot within the wall structure, ensuring the building’s long-term durability.

3. Continuous Insulation (CI) for Thermal Bridging

Thermal bridging occurs when a highly conductive material (like wood or steel studs) extends from the interior to the exterior, creating a path for heat to bypass the cavity insulation.

- The CI Solution: By installing a layer of rigid Rockwool board outside the wall framing, the entire structure is wrapped in continuous insulation. This creates an unbroken thermal envelope, significantly reducing overall heat loss (or gain) and contributing to massive long-term energy savings and overall thermal performance.

Key Benefits of Exterior Rockwool Installation

| Benefit | Description |

| Non-Combustible Fire Barrier | Offers an unparalleled level of fire resistance (up to $1000^{\circ}C$), acting as a literal fire block, essential for multi-story residential and commercial buildings. |

| Dimensional Stability | Rockwool does not shrink, sag, or shift with temperature changes, maintaining its R-value and a continuous seal for the life of the building. |

| Enhanced Acoustic Barrier | The exterior installation adds significant mass and density to the wall, providing superior acoustic insulation from outside traffic and urban noise. |

| Resilience to Elements | The material is water repellent and inhibits mold/mildew growth, ensuring its insulating properties are not compromised by weather exposure during construction or operation. |

Conclusion: A Smart Investment in Sustainability

The Rockwool insulation sheet represents a smart, long-term investment in your building’s comfort, safety, and energy efficiency. Its unique composition delivers outstanding thermal performance, crucial fire resistance, and excellent acoustic insulation, making it an ideal choice for both professional builders and DIY insulation enthusiasts. By choosing this durable insulation material, you are not only reducing your energy consumption but also enhancing the structural integrity and quietude of your space for years to come.

FAQ’S

Rockwool insulation sheet is made from natural volcanic rock (basalt) that is melted and spun into dense, fibrous wool. This structure provides excellent thermal insulation, fire resistance, and soundproofing for various applications.

Yes, Rockwool is naturally fire-resistant and can withstand extremely high temperatures. It does not burn, melt, or release toxic smoke, making it ideal for residential, commercial, and industrial fire-safety applications.

Absolutely. Rockwool’s dense fiber structure absorbs sound waves effectively, making it a popular choice for acoustic walls, studios, auditoriums, generator rooms, and HVAC systems.

The density depends on the application:

- 40–60 kg/m³ for ceiling and drywall partitions

- 80–100 kg/m³ for exterior walls and duct insulation

- 120–150 kg/m³ for industrial equipment, boilers, and fire-rated assemblies

Higher density provides better thermal and acoustic performance.