Noise pollution has become a serious concern in residential, commercial, and industrial spaces. From traffic sounds to machinery noise, unwanted sound can affect comfort, productivity, and health. Choosing the right soundproofing material plays a vital role in controlling noise effectively. Among the most widely used solutions, rockwool and glasswool stand out as reliable options.

In this guide, we provide a clear and practical comparison of Soundproofing Materials: Rockwool vs Glasswool, covering performance, safety, applications, and cost considerations to help you make an informed decision.

Understanding Soundproofing Materials

Soundproofing materials are designed to reduce sound transmission by absorbing, blocking, or dampening noise waves. The effectiveness of any sound insulation depends on density, fiber structure, installation method, and the environment where it is applied.

When comparing glass wool vs rockwool for soundproofing, both materials fall under fibrous insulation, which excels at absorbing airborne sound.

What Is Rockwool?

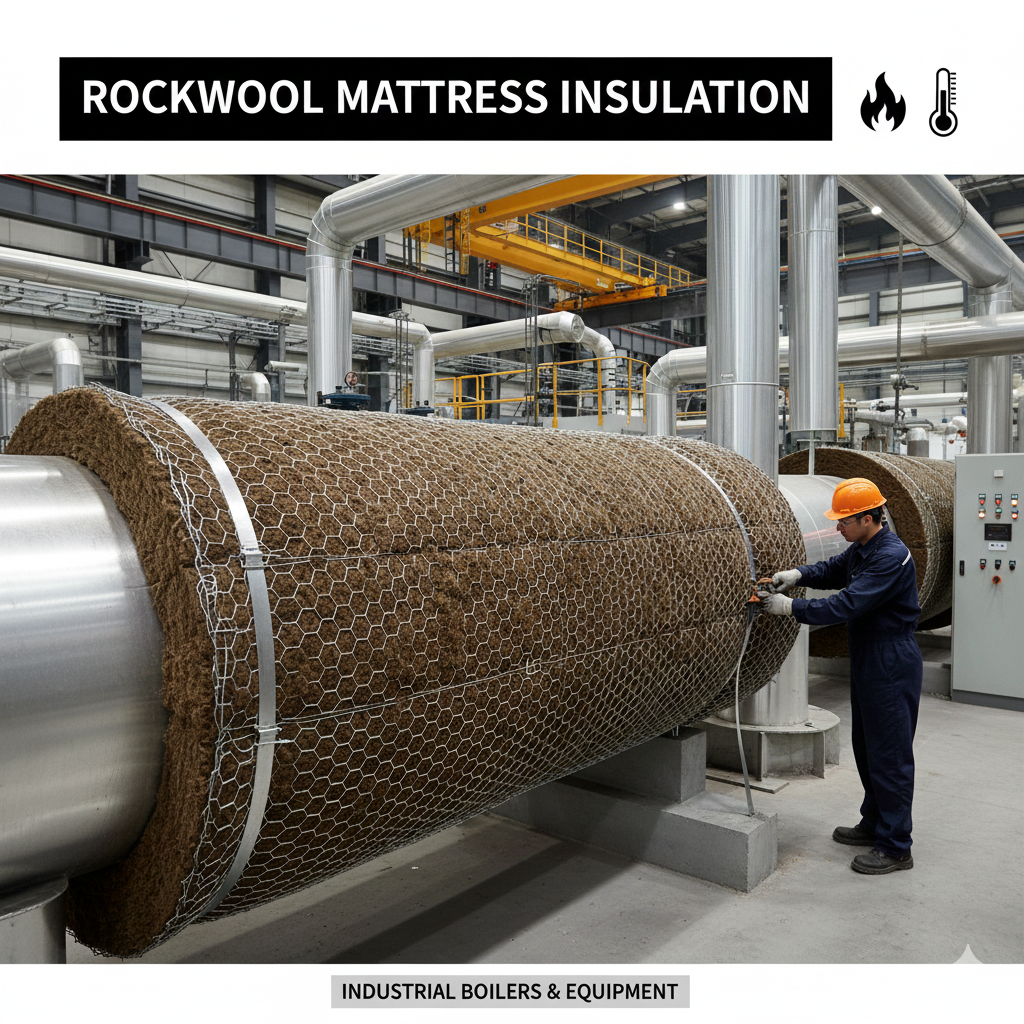

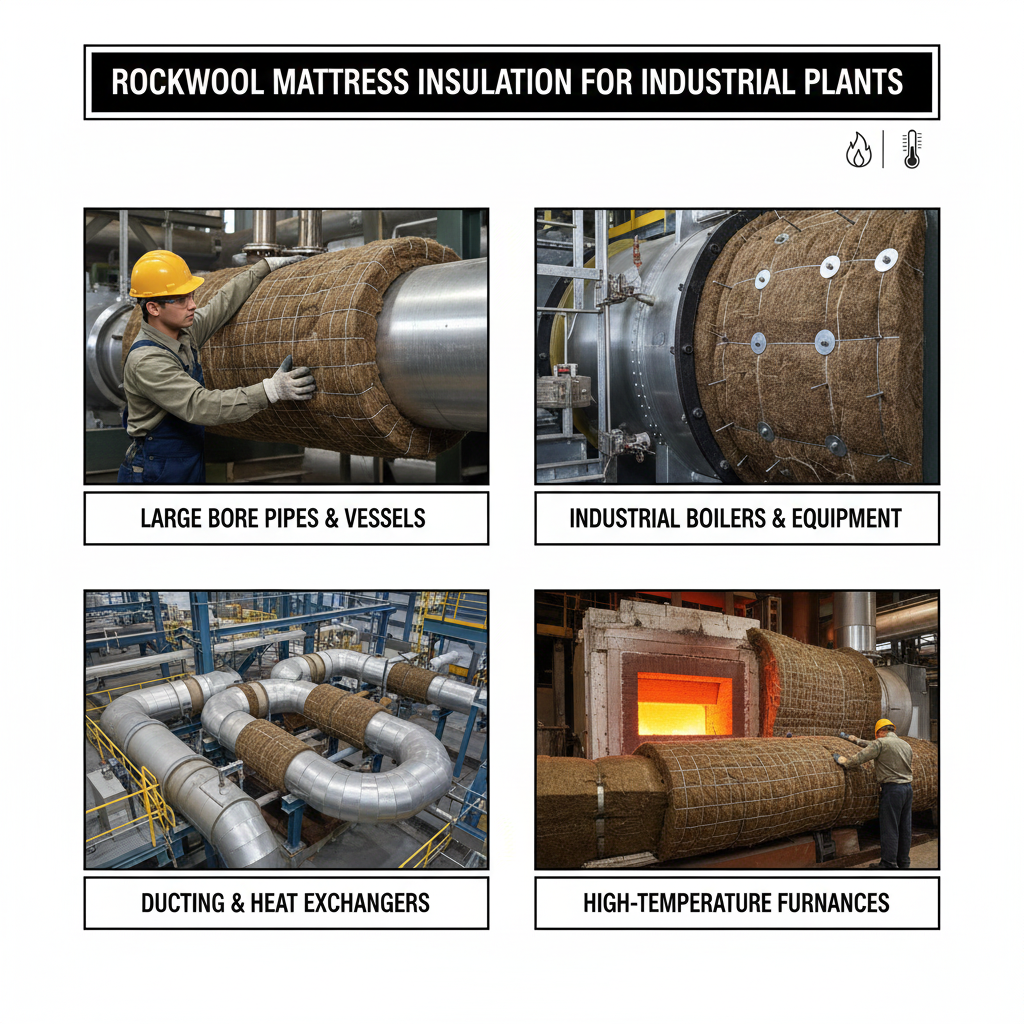

Rockwool is produced from volcanic rock and recycled slag, melted and spun into dense fibers. Its rigid structure and high mass make it a popular option in demanding sound control environments.

Key Characteristics of Rockwool

- High density and excellent sound absorption

- Strong resistance to fire and heat

- Durable structure for long-term installations

- Suitable for walls, ceilings, and industrial areas

Because of these features, many professionals consider it a best soundproofing material rockwool vs glasswool in high-noise applications.

What Is Glasswool?

Glasswool is manufactured from recycled glass and sand, processed into lightweight fibers. It is widely used in buildings for both thermal and acoustic insulation.

Key Characteristics of Glasswool

- Lightweight and flexible

- Easy to install in tight spaces

- Good acoustic absorption

- Commonly used as glasswool insulation in residential and commercial projects

Its softer fiber structure makes glass wool sound insulation particularly effective in controlling echo and background noise.

Sound Performance Comparison

When evaluating glass wool vs rockwool for soundproofing, performance depends on the type of noise and the installation area.

Rockwool performs better at blocking low-frequency sounds such as machinery or heavy traffic. Glasswool, on the other hand, is very effective at absorbing mid- to high-frequency sounds like voices and office noise.

In studios, offices, and homes, both materials deliver reliable acoustic comfort when installed correctly.

Health and Safety Considerations

A common concern among users is rockwool vs glasswool health impact. Both materials are safe when handled and installed properly.

Rockwool fibers are generally thicker, reducing airborne particles during installation. Glasswool fibers are finer and may cause mild skin or respiratory irritation if protective gear is not used. Proper safety measures, such as gloves and masks, eliminate these risks.

Cost and Pricing Factors

The Soundproofing Materials Rockwool vs Glasswool price varies based on thickness, density, and application area. Typically, rockwool is priced higher due to its density and durability.

From a budgeting perspective, Soundproofing Materials Rockwool vs Glasswool cost should be evaluated alongside long-term performance. While glasswool may have a lower upfront cost, rockwool often provides better durability in demanding environments.

Applications and Use Cases

Where Rockwool Works Best

- Industrial facilities

- Generator rooms

- Recording studios

- Commercial buildings

Where Glasswool Works Best

- Homes and apartments

- Offices and meeting rooms

- HVAC duct lining

- False ceilings

Both materials are effective solutions depending on project needs and sound control goals.

Which One Should You Choose?

If your priority is maximum noise reduction and durability, rockwool is often the better choice. If flexibility, ease of installation, and budget are more important, glasswool delivers excellent value.

In many modern projects, a combination of both materials is used to achieve optimal sound control across different areas.

Final Verdict

Choosing between Soundproofing Materials Rockwool vs Glasswool depends on sound type, environment, budget, and safety requirements. Both materials are proven performers in acoustic insulation and continue to be trusted worldwide.

By understanding their differences, you can confidently select the right solution for your soundproofing needs.

FAQ’S

Rockwool generally performs better for heavy noise control due to its higher density, making it ideal for studios and industrial areas. Glasswool is effective for reducing echo and airborne noise in homes and offices.

Yes, glasswool insulation is safe when installed properly. Using gloves, masks, and protective clothing during installation prevents irritation, making it suitable for residential and commercial use.

Rockwool absorbs low-frequency sounds more effectively, while glass wool sound insulation works well for mid and high frequencies. The choice depends on the type of noise you want to control.

Soundproofing materials rockwool vs glasswool cost varies by density and thickness. Rockwool is usually more expensive, but it offers higher durability and long-term performance.