When selecting insulation for buildings, one technical factor plays a decisive role in performance: thermal conductivity. Understanding how different materials perform helps engineers, architects, and homeowners choose the most efficient insulation system. This guide presents a clear thermal conductivity comparison EPS XPS Rockwool, explaining how each material works and where it performs best.

Understanding Thermal Conductivity in Insulation

Thermal conductivity measures how easily heat flows through a material. Lower thermal conductivity means better insulation performance. Materials with low conductivity slow down heat transfer, keeping interiors cooler in summer and warmer in winter.

This property directly affects:

- Energy efficiency

- Cooling and heating costs

- Indoor comfort

Overview of Common Insulation Materials

The most widely used insulation materials in construction include:

- EPS (Expanded Polystyrene)

- XPS (Extruded Polystyrene)

- Rockwool (Mineral Wool)

Each material differs in structure, density, and heat resistance.

EPS Foam – Structure and Thermal Performance

EPS foam is manufactured by expanding polystyrene beads and fusing them together. The trapped air inside the beads provides insulation.

Key Characteristics of EPS Foam

- Lightweight

- Cost-effective

- Moderate thermal resistance

- Higher water absorption than XPS

EPS is commonly used in walls, roofs, and packaging. Interestingly, EPS foam surfboard cores also use similar material properties due to lightweight strength and buoyancy, though construction-grade EPS differs in density.

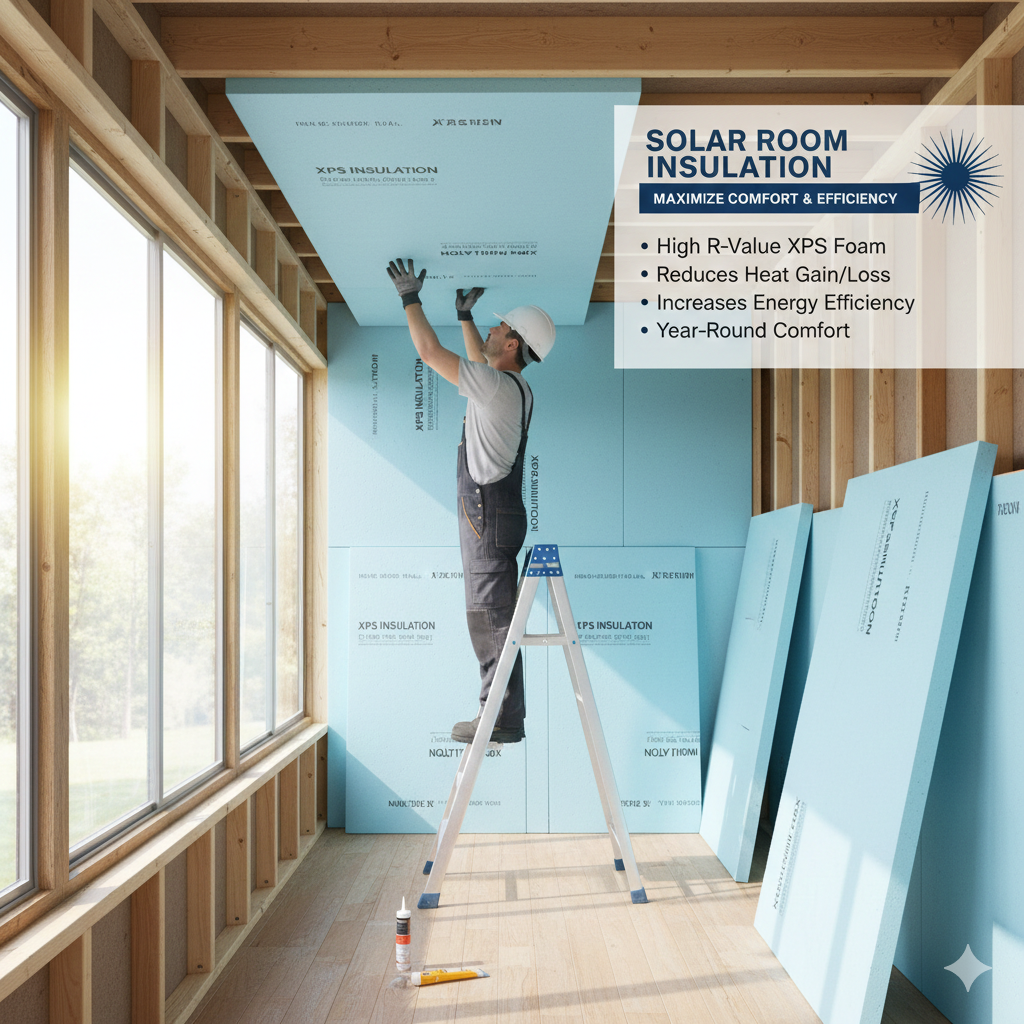

XPS Foam – High-Performance Insulation

XPS foam is produced using an extrusion process, creating a closed-cell structure that improves strength and moisture resistance.

Key Characteristics of XPS Foam

- Lower thermal conductivity than EPS

- High compressive strength

- Excellent moisture resistance

- Long service life

Because of these properties, XPS is preferred in demanding environments such as foundations, roofs, and exposed insulation areas.

Rockwool – Mineral-Based Thermal Control

Rockwool is made from molten volcanic rock spun into fibers. Unlike foam-based insulation, rockwool is inorganic and fire-resistant.

Key Characteristics of Rockwool

- Stable thermal performance

- Fire resistance

- Sound absorption

- Heavier than EPS and XPS

While rockwool has slightly higher thermal conductivity compared to XPS, it offers additional benefits like acoustic insulation.

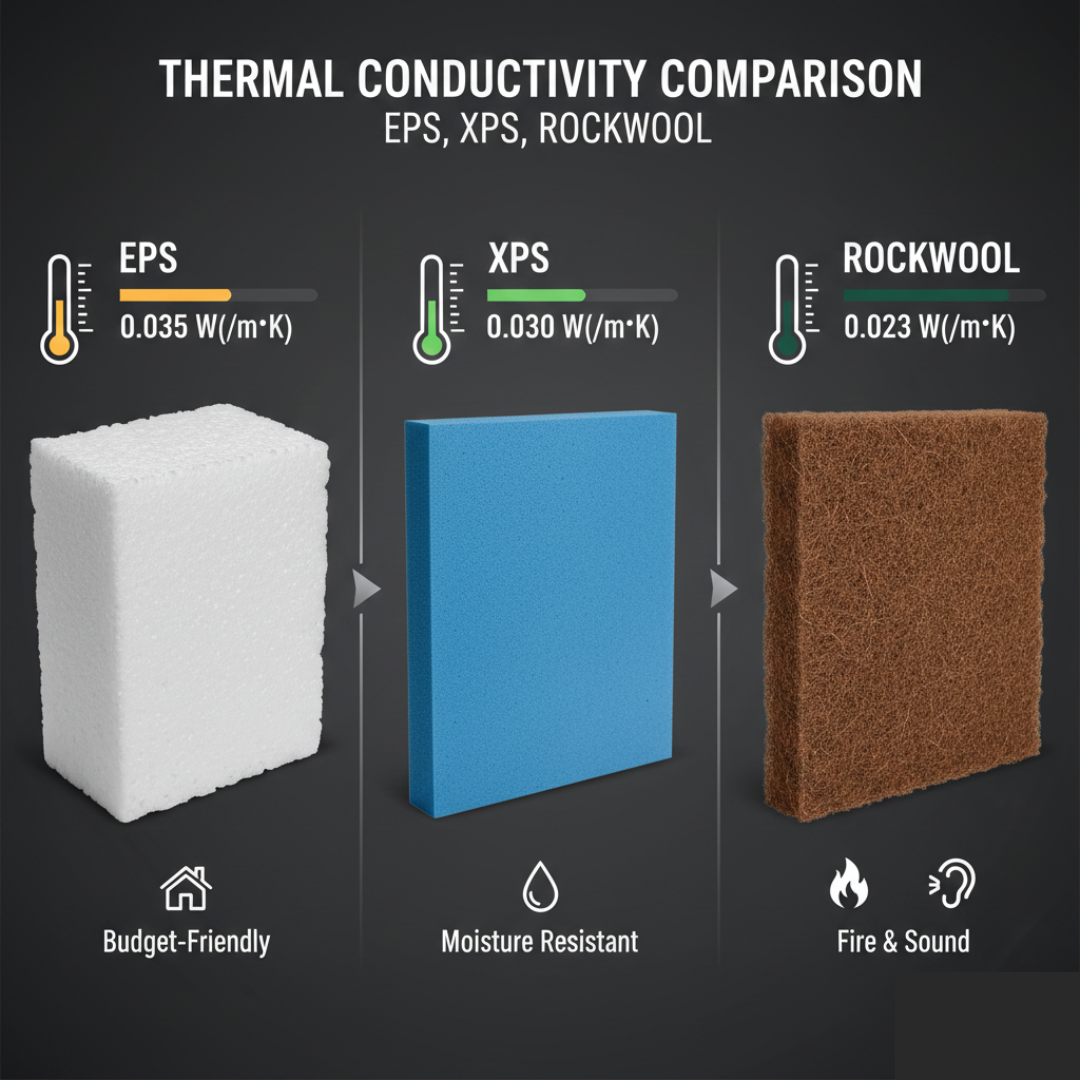

Thermal Conductivity Comparison: EPS, XPS, Rockwool

Below is a simplified comparison based on general performance ranges:

| Material | Thermal Conductivity (W/m·K) | Moisture Resistance | Structural Strength |

|---|---|---|---|

| EPS | Moderate | Medium | Low |

| XPS | Low | High | High |

| Rockwool | Moderate | High | Medium |

This thermal conductivity comparison EPS XPS Rockwool shows why XPS is often selected where maximum thermal efficiency is required.

EPS vs XPS R Value Explained

R-value measures resistance to heat flow. Higher R-value means better insulation.

When comparing EPS vs XPS R value:

- XPS generally provides higher R-value per inch

- EPS requires greater thickness to achieve similar performance

This difference makes XPS vs EPS an important comparison in space-limited designs.

How to Convert Thermal Conductivity to U Value

Engineers often need to convert thermal conductivity to U value to evaluate overall building performance.

- Thermal conductivity measures material performance

- U-value measures heat loss through an entire building element

Lower U-value indicates better insulation. Material thickness and layering directly affect the final U-value.

Choosing the Right Material Based on Application

EPS Foam Is Suitable

- Budget-focused projects

- Wall insulation

- Lightweight applications

XPS Foam Is Ideal

- Roofs and foundations

- High moisture areas

- Space-constrained insulation

Rockwool Is Preferred

- Fire-sensitive environments

- Acoustic insulation needs

- Industrial and commercial buildings

Final Thoughts

Understanding insulation performance requires more than price comparison. A clear thermal conductivity comparison EPS XPS Rockwool highlights how each material behaves under real-world conditions. While EPS foam offers affordability, XPS foam delivers superior thermal resistance, and rockwool adds fire and sound control benefits.

The right insulation choice depends on performance goals, environmental exposure, and building design.

FAQ’S

Among EPS, XPS, and rockwool, XPS foam generally has the lowest thermal conductivity. This means it offers better thermal resistance with less thickness compared to EPS foam and rockwool.

To convert thermal conductivity to U value, divide the material’s thermal conductivity by its thickness and include all layers of the building element. A lower U value indicates better insulation performance.

The main difference in XPS vs EPS lies in structure and performance. XPS has a closed-cell structure, higher compressive strength, better moisture resistance, and a higher R value than EPS.

Yes, EPS foam is suitable for many building applications, especially walls and roofs where budget-friendly insulation is needed. However, for moisture-prone areas, XPS foam performs better.