Fire safety has become one of the most critical considerations in modern construction. Among insulation materials, Rockwool stands out due to its exceptional fire-resistant properties. This blog provides a detailed breakdown of Rockwool Fire Resistance Test & Results, explaining how it performs under extreme heat, what ratings mean in real-world applications, and why it is widely trusted in fire-rated construction systems.

Why Fire Resistance Matters in Insulation Materials

During a fire, insulation can either slow down flame spread or accelerate it. Materials with poor fire performance contribute to structural failure and smoke development. Rockwool, made from mineral fibers, is designed to withstand extremely high temperatures while maintaining its structural integrity.

Understanding rockwool fire resistance helps builders, architects, and homeowners make safer material choices for walls, ceilings, and structural assemblies.

What Is Rockwool and Why Is It Fire Resistant?

Rockwool is a type of mineral wool insulation manufactured from natural volcanic rock. These fibers are inherently non-combustible, meaning they do not ignite, melt, or release toxic smoke when exposed to fire.

This composition directly influences rockwool fire performance, allowing it to act as a passive fire protection material rather than just thermal insulation.

Rockwool Fire Resistance Test: How It Is Evaluated

Fire resistance testing measures how long a material or system can withstand fire exposure while maintaining:

- Structural stability

- Integrity (no flame penetration)

- Insulation (limited heat transfer)

During standardized fire tests, Rockwool insulation is exposed to temperatures exceeding 1,000°C, simulating real fire conditions.

Rockwool 1 Hour Fire Barrier Explained

A common fire safety requirement in residential and commercial buildings is a rockwool 1 hour fire barrier. This means the insulation system can resist fire for at least 60 minutes without collapse or flame spread.

In wall and floor assemblies, Rockwool significantly delays heat transmission, providing valuable time for evacuation and emergency response.

Fire Test Results: How Rockwool Performs Under Heat

Based on controlled fire exposure, Rockwool demonstrates consistent and reliable behavior:

- Does not ignite or drip

- Maintains fiber structure at high temperatures

- Limits flame spread through cavities

These results clearly highlight strong rockwool fire performance, even in prolonged fire scenarios.

Rockwool Fire Rated Wall Panels

Rockwool fire rated wall panels are engineered systems that combine insulation with fire-rated boards or cladding. These panels are commonly used in:

- Stairwells

- Fire escape corridors

- Industrial buildings

- High-rise residential projects

Their ability to resist fire penetration makes them ideal for compartmentalization and fire zoning.

Mineral Wool Insulation Fire Rating

The mineral wool insulation fire rating is typically classified as non-combustible. Rockwool insulation does not contribute to fire load and helps meet strict building code requirements.

This rating makes mineral wool suitable for applications where fire compliance is mandatory, such as hospitals, schools, and commercial structures.

Rockwool vs Other Insulation Materials in Fire Conditions

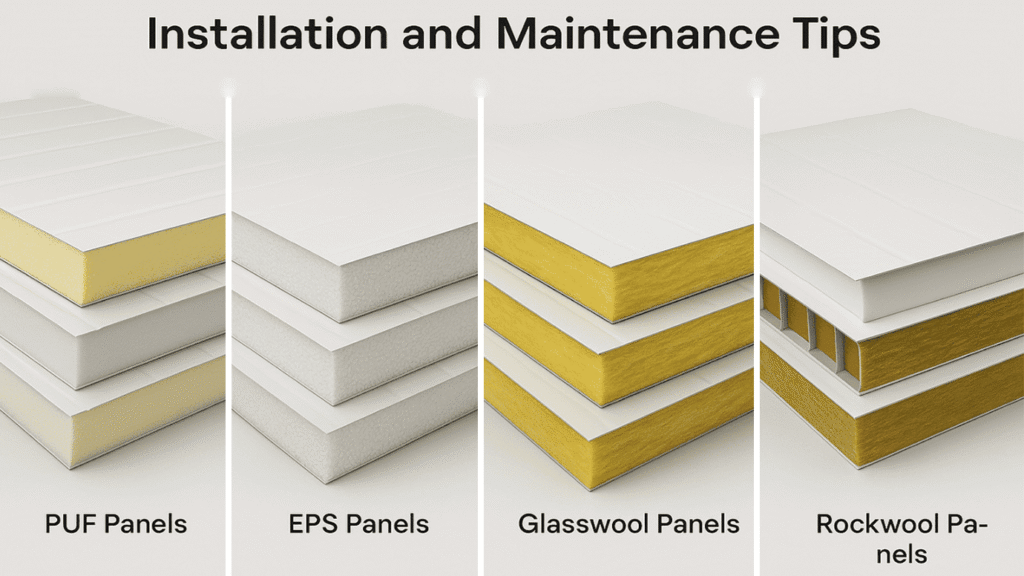

Compared to foam-based insulation or plastic-derived boards, Rockwool offers superior fire safety. While some materials may melt or release smoke, Rockwool remains stable and continues to act as a thermal barrier.

This comparison further reinforces the value of rockwool fire resistance in high-risk environments.

Where Rockwool Fire Resistance Is Most Effective

Rockwool insulation is commonly used in:

- Fire-rated walls and partitions

- Ceiling voids and shafts

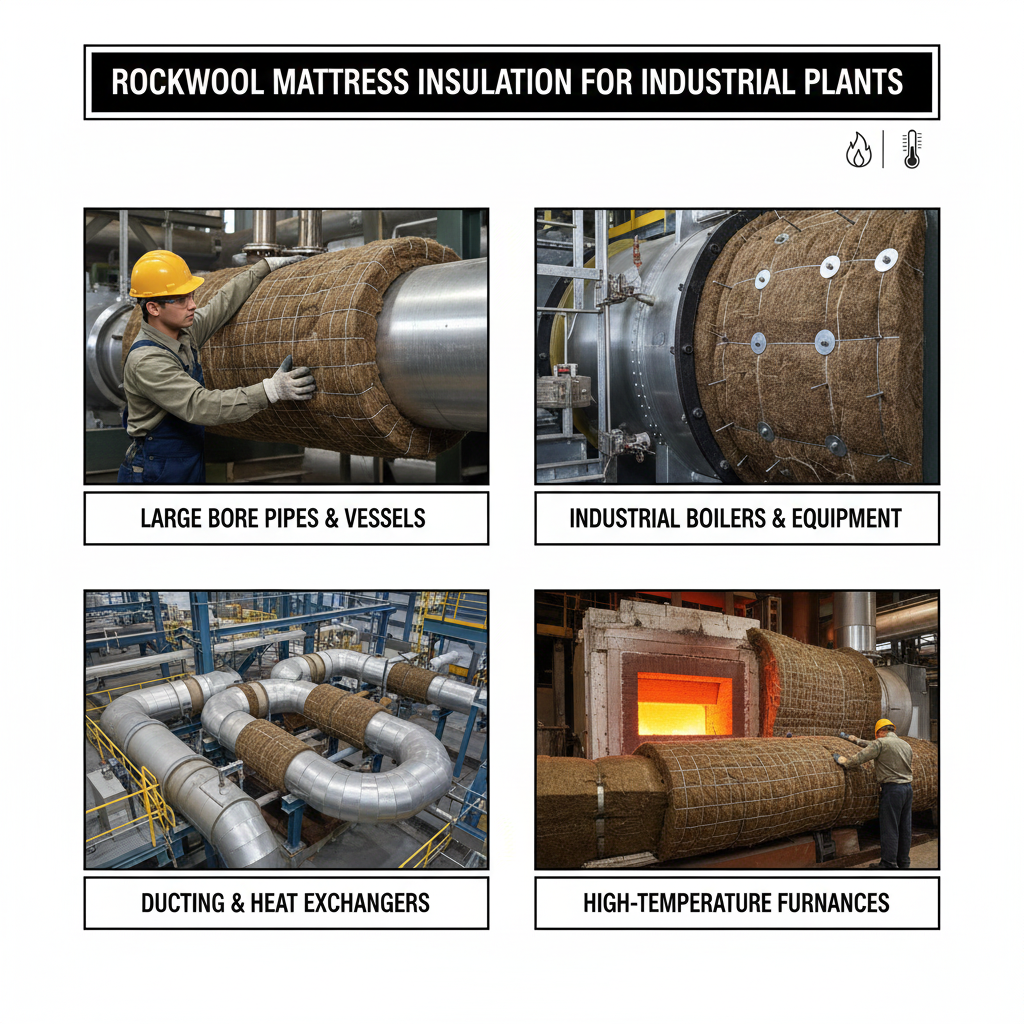

- Industrial plants

- Residential buildings requiring enhanced fire safety

Its versatility allows it to integrate seamlessly into various construction systems without compromising safety.

Limitations and Considerations

While Rockwool performs exceptionally in fire conditions, correct installation is essential. Gaps, compression, or improper fixing can reduce overall system performance.

Fire resistance ratings always apply to complete assemblies, not just the insulation material alone.

Conclusion

The Rockwool Fire Resistance Test & Results clearly demonstrate why Rockwool is one of the most reliable fire-resistant insulation materials available today. With its ability to form a rockwool 1 hour fire barrier, support fire rated wall panels, and meet stringent mineral wool insulation fire rating standards, Rockwool plays a vital role in modern fire-safe construction.

Choosing Rockwool is not just an insulation decision—it is a commitment to safety, durability, and compliance.

FAQ’S

Rockwool insulation is non-combustible and can withstand extremely high temperatures. Its fire resistance performance helps slow fire spread and reduce heat transfer during a fire.

A rockwool 1 hour fire barrier means the insulation system can resist fire exposure for at least 60 minutes without allowing flame penetration or structural failure.

Rockwool fire resistance is tested under controlled conditions where insulation systems are exposed to high temperatures to evaluate integrity, insulation, and stability over time.

Yes, rockwool fire rated wall panels are widely used in residential buildings, especially in staircases, corridors, and partition walls that require enhanced fire protection.

Rockwool fire performance is significantly better than foam insulation because it does not melt, drip, or release toxic smoke when exposed to fire.

The mineral wool insulation fire rating is typically classified as non-combustible, meaning it does not contribute to fire load or flame spread.

Yes, Rockwool insulation is commonly used to meet building fire safety codes due to its high fire resistance and compatibility with fire-rated construction systems.

Rockwool fire insulation is commonly used in fire-rated walls, ceilings, shafts, industrial facilities, and residential buildings where fire safety is a priority.