As construction activity grows across Rawalpindi, demand for thermal and acoustic insulation materials has increased rapidly. From residential homes to commercial and industrial buildings, buyers are actively comparing insulation types and prices before making decisions. This guide explores Rawalpindi insulation market prices, material trends, and factors that influence costs—helping buyers make informed choices.

Overview of Insulation Demand in Rawalpindi

Rawalpindi experiences extreme summer heat and cooler winters, making insulation a practical necessity rather than a luxury. Builders and homeowners now prioritize materials that reduce energy consumption, improve indoor comfort, and enhance fire safety.

Among the most commonly traded insulation products in the local market are glass wool, rockwool, and mineral wool, each offering different performance levels and price points.

Glass Wool Market Pricing Trends

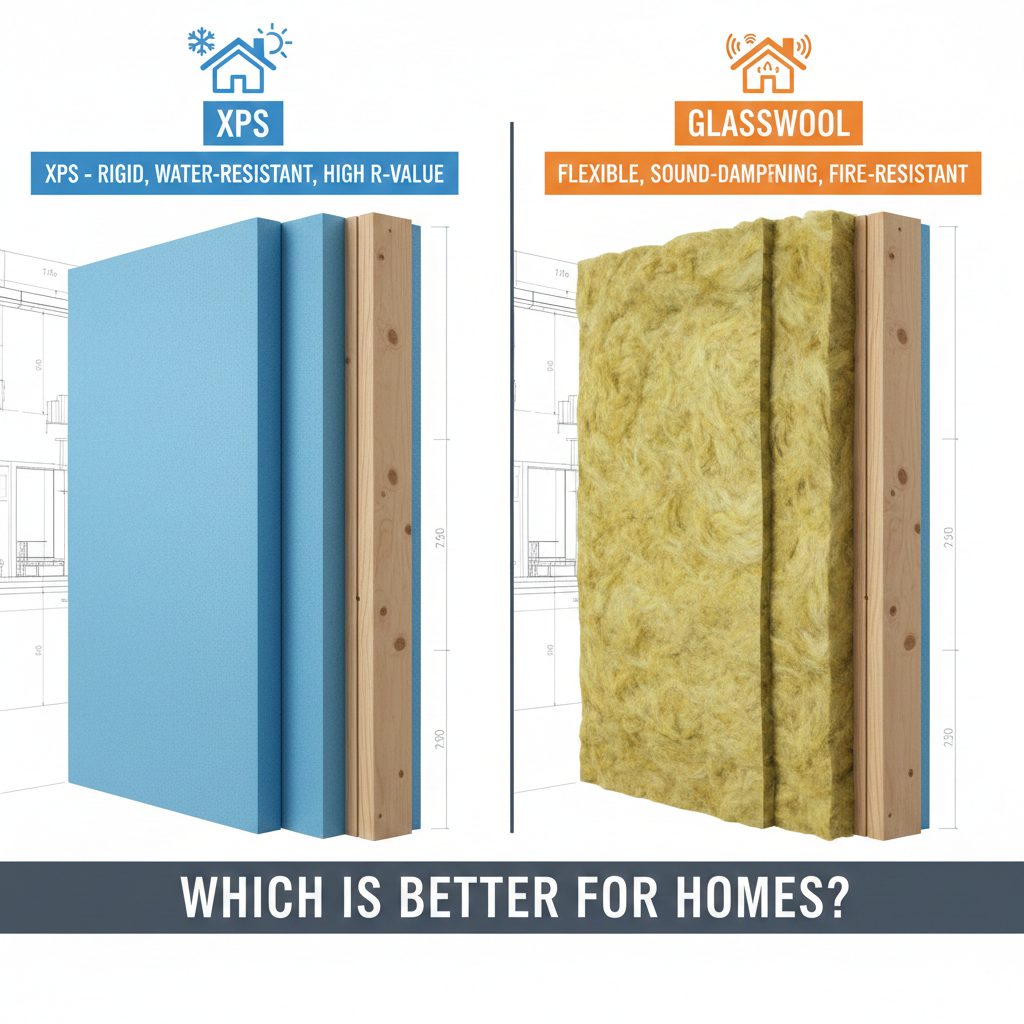

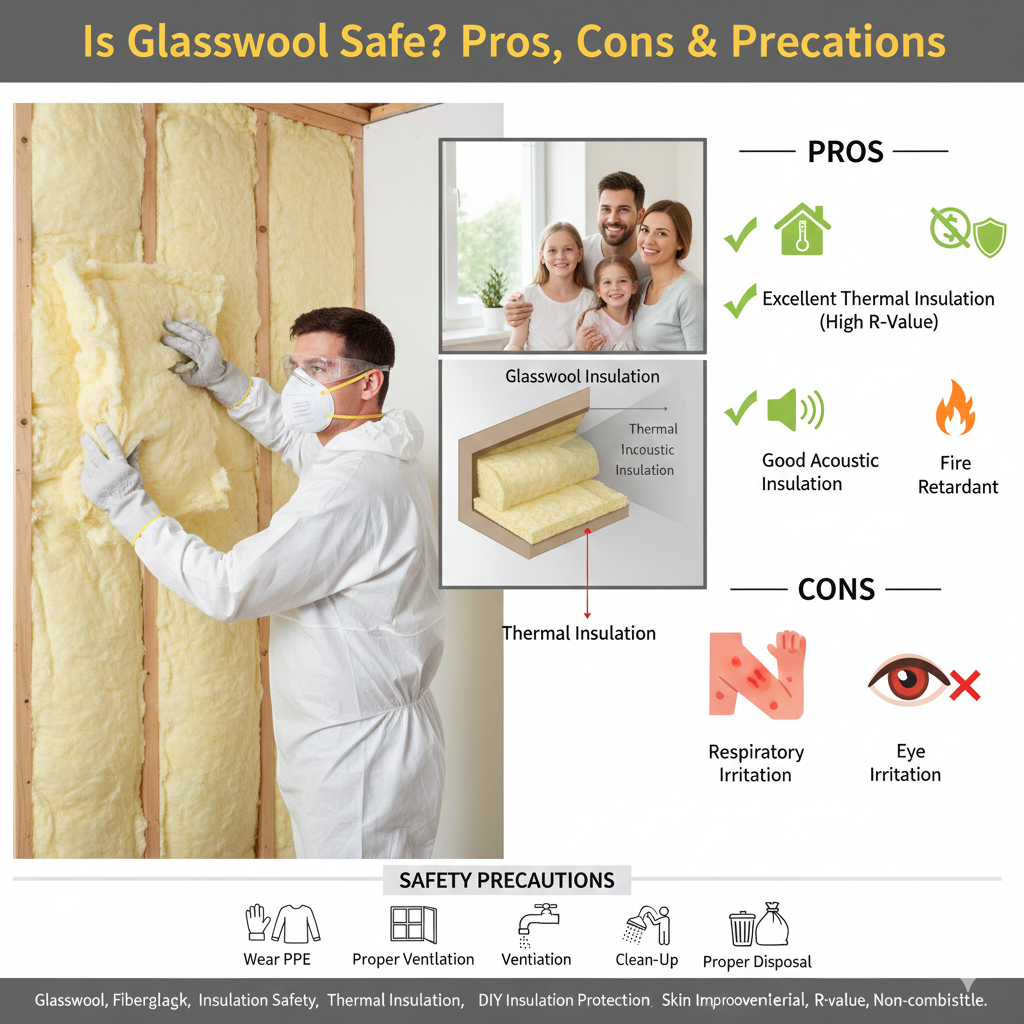

Glass wool remains one of the most widely used insulation materials due to its affordability and ease of installation. The glass wool price in Rawalpindi depends on density, thickness, and facing type (plain or foil-faced).

While Rawalpindi has its own pricing structure, many suppliers also benchmark rates against major cities. As a result, glass wool price in Lahore often influences wholesale trends, especially for bulk purchases. Contractors sourcing glass wool insulation in Lahore sometimes supply Rawalpindi projects when availability fluctuates.

Across Pakistan, the glass wool price in Pakistan varies based on imported raw materials, energy costs, and demand cycles.

Rockwool Insulation Prices in the Local Market

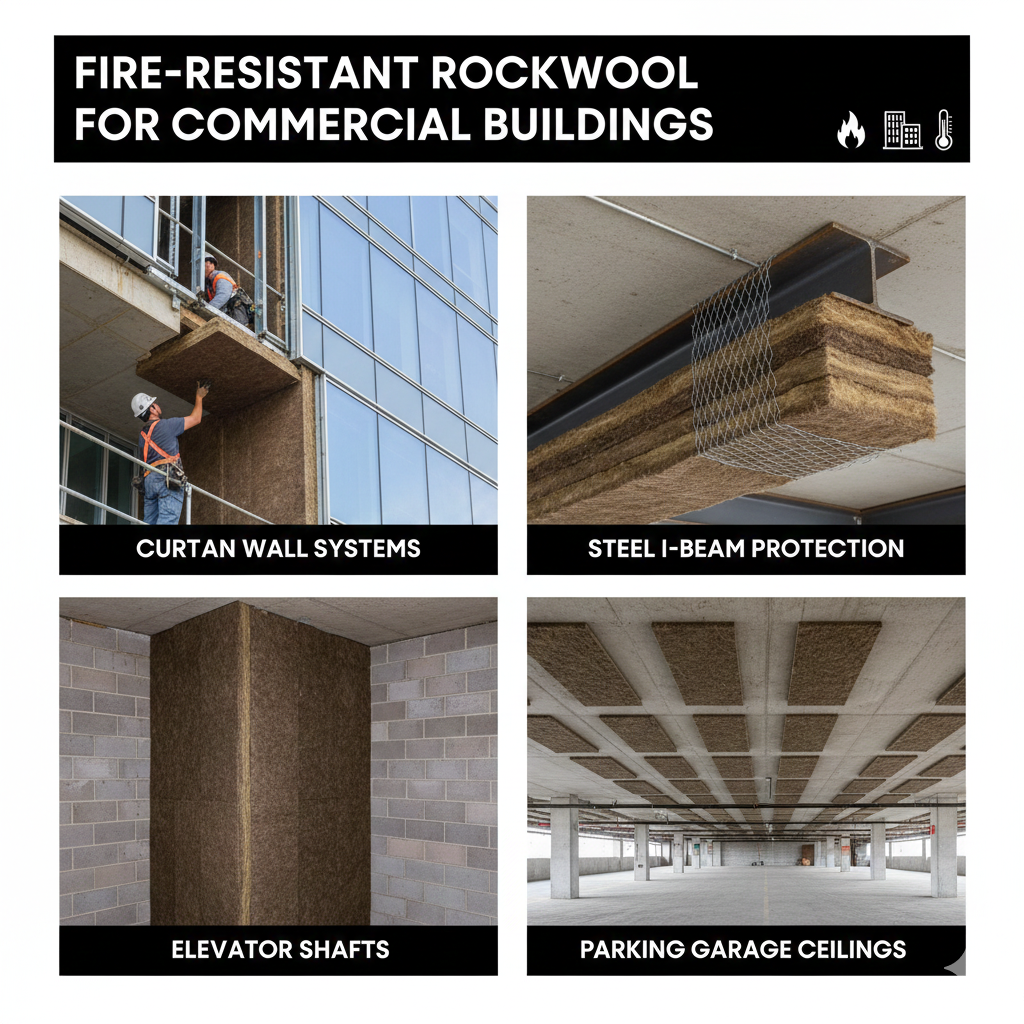

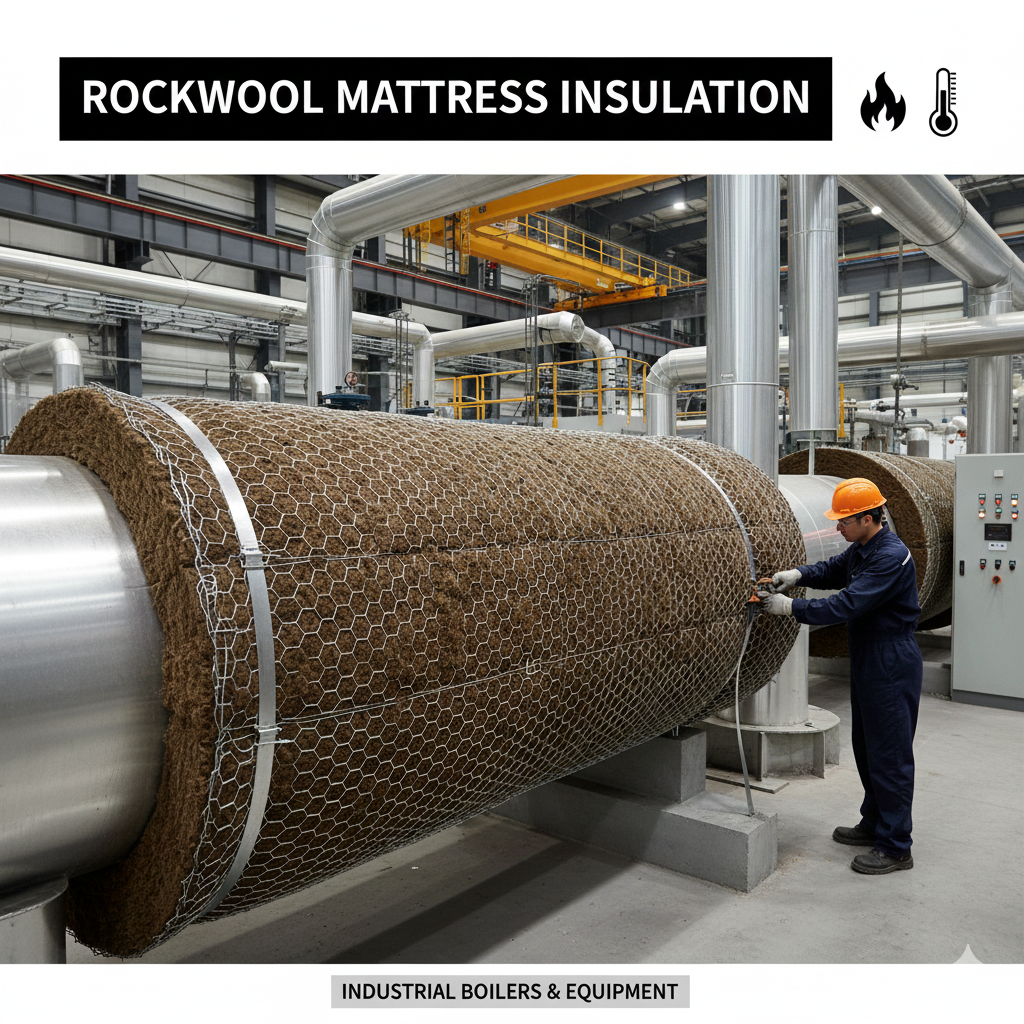

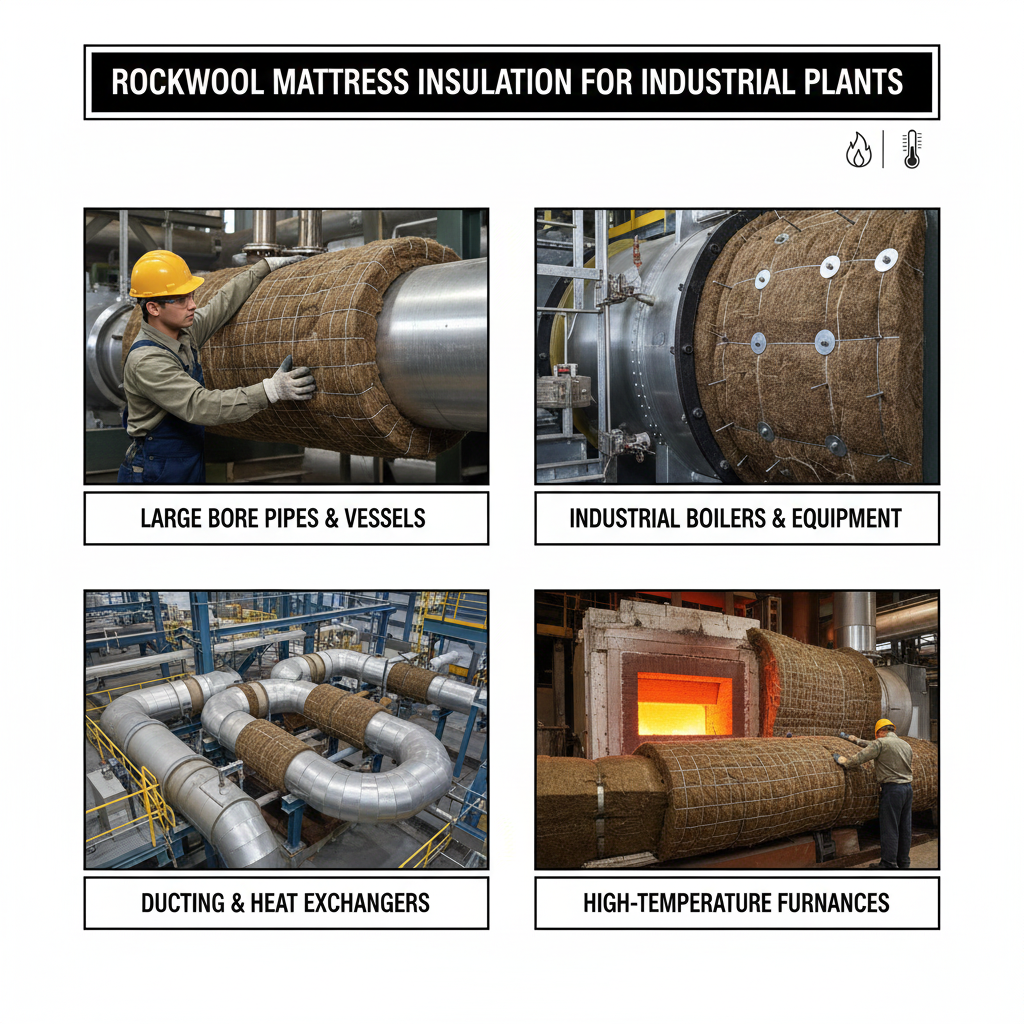

Rockwool is increasingly preferred for applications requiring fire resistance and higher acoustic performance. In Rawalpindi, demand for this material has grown in commercial buildings and industrial facilities.

The rockwool insulation price in Pakistan is generally higher than glass wool due to its superior fire rating and density. Buyers comparing suppliers often evaluate the rock wool insulation price based on slab thickness and compressive strength.

Local distributors offering rockwool insulation Pakistan products usually maintain stock for large-scale construction projects, where durability and fire safety are critical.

Rawalpindi Insulation Price Comparison Table

| Insulation Material | Typical Density (kg/m³) | Common Use | Relative Price Level |

|---|---|---|---|

| Glass Wool | 12 – 24 | Roofs, ceilings, ducts | Low |

| Mineral Wool | 30 – 60 | Walls, partitions | Medium |

| Rockwool | 40 – 120 | Fire-rated walls, industrial use | High |

| Glass Wool (Foil Faced) | 16 – 32 | Thermal + radiant control | Medium |

| High-Density Rockwool | 80 – 120 | Acoustic & fire insulation | High |

Note: Prices vary by supplier, thickness, and market demand.

Mineral Wool Pricing and Applications

Mineral wool, which includes both glass wool and rockwool variants, is also traded separately in the Rawalpindi market. The mineral wool price in Pakistan depends on whether the product is intended for thermal insulation, soundproofing, or fire-rated systems.

Mineral wool is commonly used in:

- Partition walls

- Industrial sheds

- HVAC duct insulation

- Fire-rated ceiling systems

Its versatility keeps demand stable throughout the year.

Factors Affecting Insulation Prices in Rawalpindi

Several elements influence insulation pricing in the Rawalpindi market:

- Material Density & Thickness

Higher density products provide better insulation but cost more. - Imported vs Local Supply

Imported insulation products tend to raise overall pricing trends. - Seasonal Demand

Prices often rise before peak summer due to increased demand. - Transportation Costs

Rates from Lahore or Karachi impact local pricing structures. - Bulk Purchase Volume

Wholesale buyers usually secure better pricing.

Choosing the Right Insulation Material

Selecting insulation should not be based on price alone. Buyers must consider application type, building design, and long-term energy savings. Glass wool works well for budget-focused residential projects, while rockwool is better suited for fire-sensitive areas. Mineral wool offers a balance between thermal and acoustic performance.

Understanding local price trends allows buyers to plan procurement efficiently without compromising quality.

Rawalpindi Insulation Market Outlook

With growing awareness around energy efficiency, the Rawalpindi insulation market is expected to expand steadily. Demand for higher-performance insulation materials will continue to influence pricing, while competition among suppliers may stabilize costs over time.

Staying updated on market trends helps contractors, builders, and homeowners secure the best value.

FAQ’S

The glass wool price in Rawalpindi depends on density, thickness, and facing type. Prices generally follow the national trend of the glass wool price in Pakistan, with slight variation based on local availability.

Yes, glass wool is usually more economical. Rockwool insulation price in Pakistan is higher due to its superior fire resistance, durability, and sound insulation properties.

Many distributors source insulation materials from Lahore. As a result, fluctuations in glass wool price in Lahore often impact Rawalpindi’s insulation market.

Mineral wool price in Pakistan varies depending on whether it is glass-based or stone-based. Rockwool generally costs more due to higher density and fire performance.

Yes, rockwool insulation Pakistan products are suitable for residential use, especially where fire safety and sound insulation are priorities.

Rockwool offers long-term value through durability and fire resistance, while glass wool is ideal for cost-effective thermal insulation in standard applications.