Fire safety is no longer optional for commercial buildings—it is a core requirement. From factories and warehouses to commercial kitchens and office complexes, choosing the right fireproof insulation plays a critical role in protecting lives, assets, and business continuity. This guide explains how to select the best fireproof insulation sheets for commercial use, with a practical focus on performance, fire ratings, and real-world applications in Pakistan.

Why Fireproof Insulation Is Essential for Commercial Buildings

Commercial environments face higher fire risks due to:

- Electrical loads

- Machinery heat

- Cooking operations

- Storage of flammable materials

Fireproof insulation slows the spread of flames, limits structural damage, and provides valuable evacuation time. In many cases, using fire-rated insulation is also required to meet building safety standards and insurance conditions.

Understanding Fire Ratings in Insulation Materials

Fire ratings measure how long an insulation system can resist fire exposure without failure.

🔥 1 Hour Fire Rated Insulation

- Provides short-term fire resistance

- Common in internal partitions and service areas

- Helps delay fire spread between rooms

🔥 2 Hour Fire Rated Insulation

- Designed for high-risk commercial zones

- Maintains structural integrity longer

- Often required in industrial and large-scale facilities

Selecting 1 hour fire rated insulation or 2 – hour fire rated insulation depends on building usage, occupancy level, and fire load.

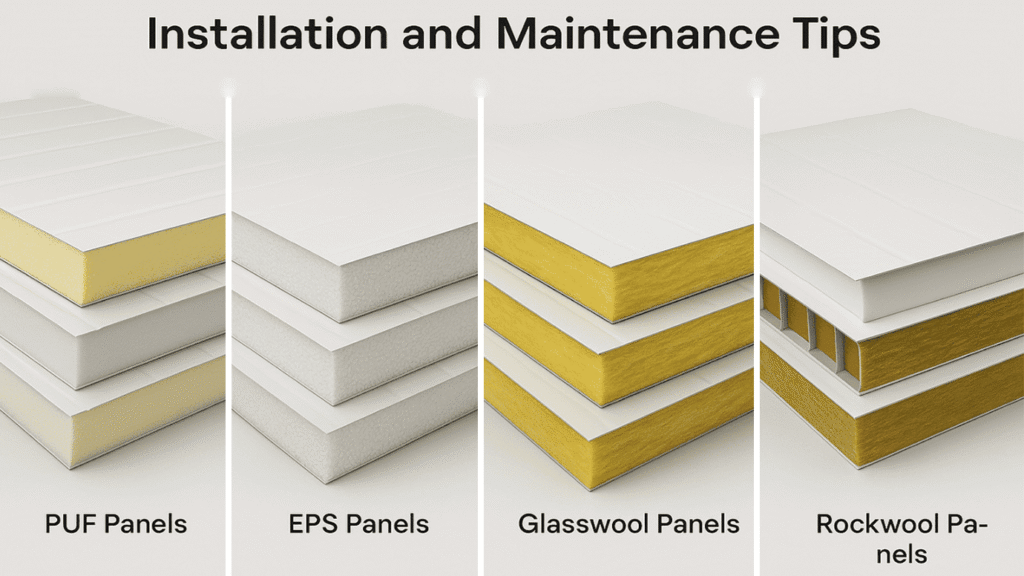

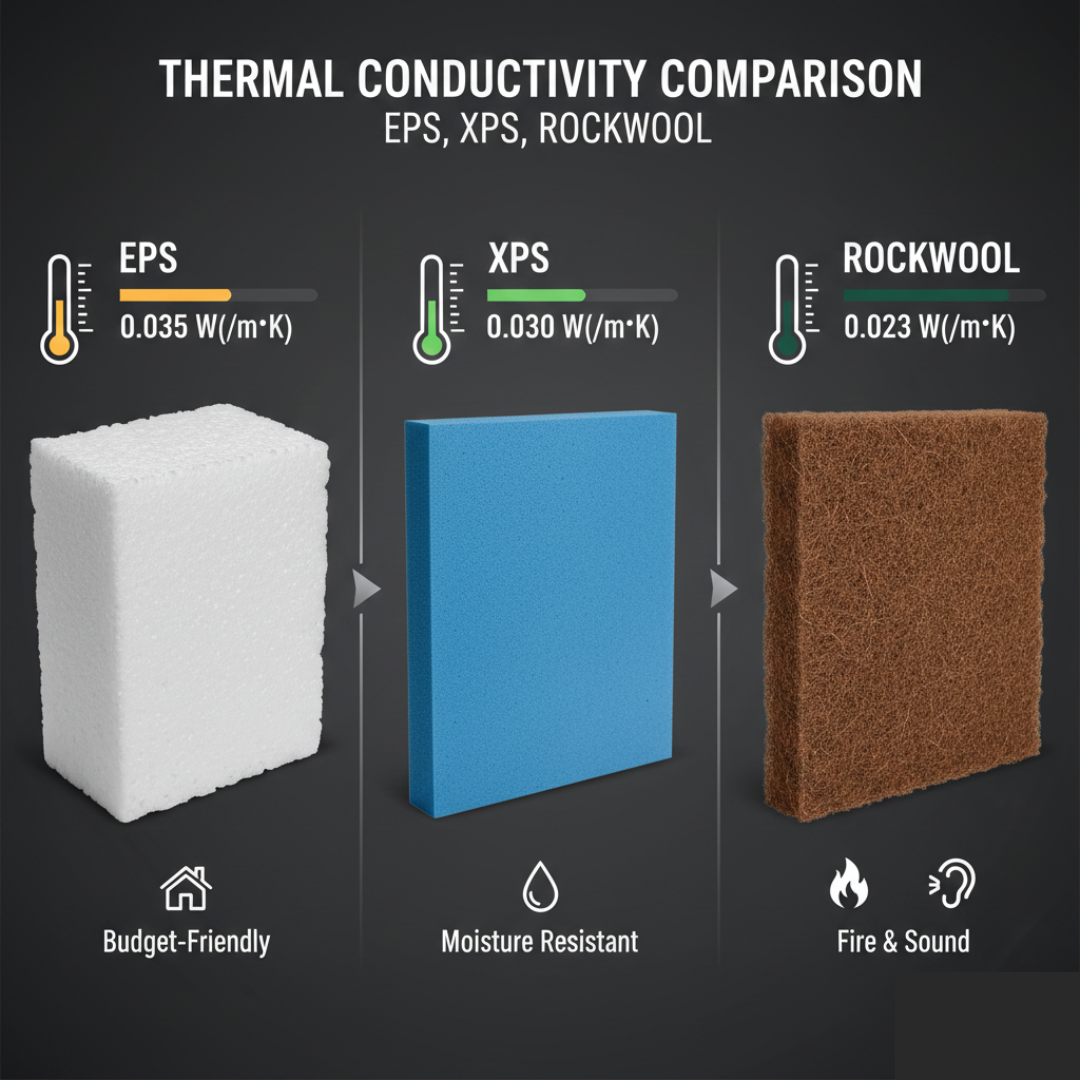

Technical Comparison Table – Fireproof Insulation Materials

| Insulation Type | Fire Rating | Thermal Performance | Common Applications | Moisture Resistance |

|---|---|---|---|---|

| Rockwool Insulation | Up to 2 Hours | High | Walls, ceilings, industrial areas | High |

| Fireproof Insulation Board | 1–2 Hours | Medium | Partitions, shafts, stairwells | Medium |

| Fireproof Sheets (Kitchen) | 1 Hour | Medium | Commercial kitchens, ducts | Medium |

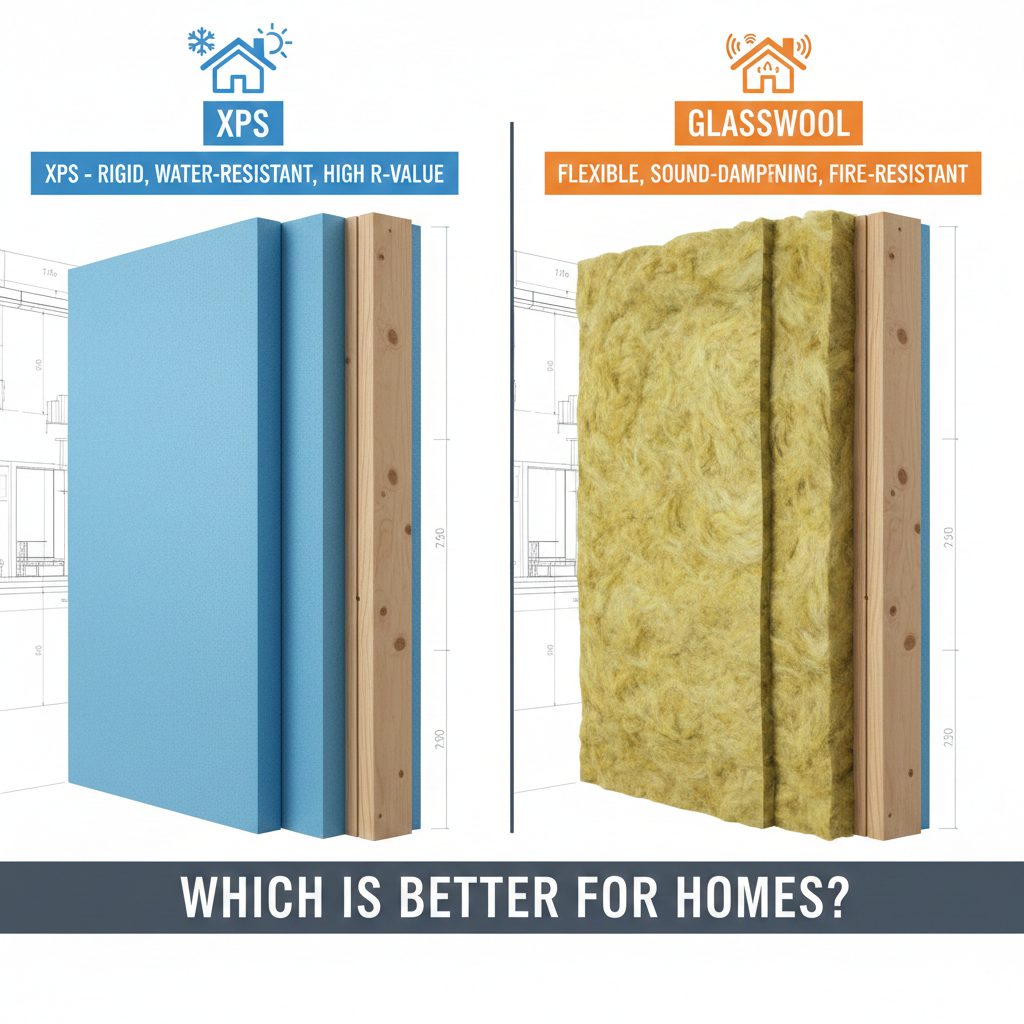

| EPS Sheets | Low | Medium | Non-fire-rated areas | Low |

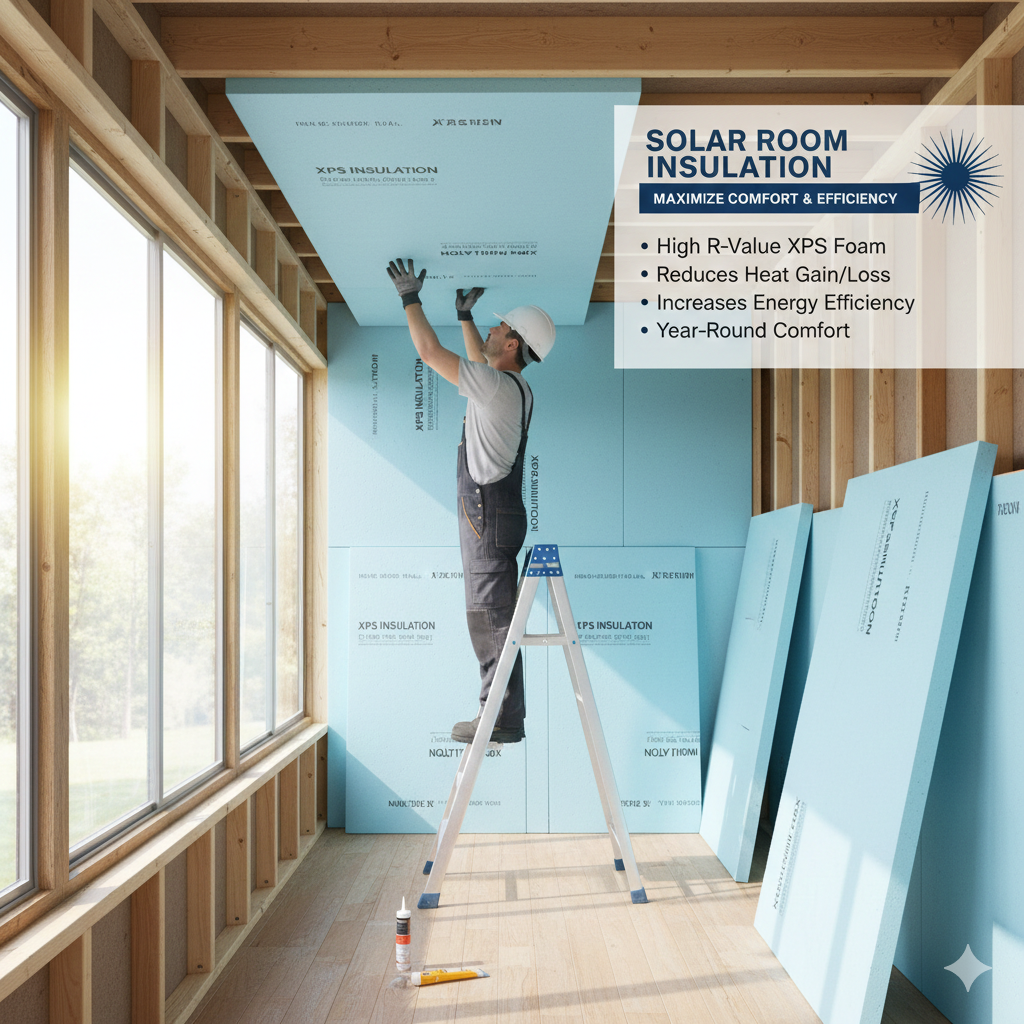

| XPS Boards | Low | High | Thermal-only insulation | High |

Note: Only mineral-based insulation materials are recommended where fire safety is a priority.

Best Fireproof Insulation Sheets for Commercial Use in Pakistan

Below are the most effective options used across commercial projects.

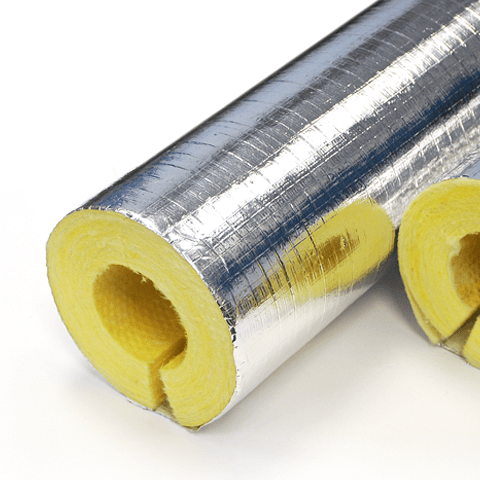

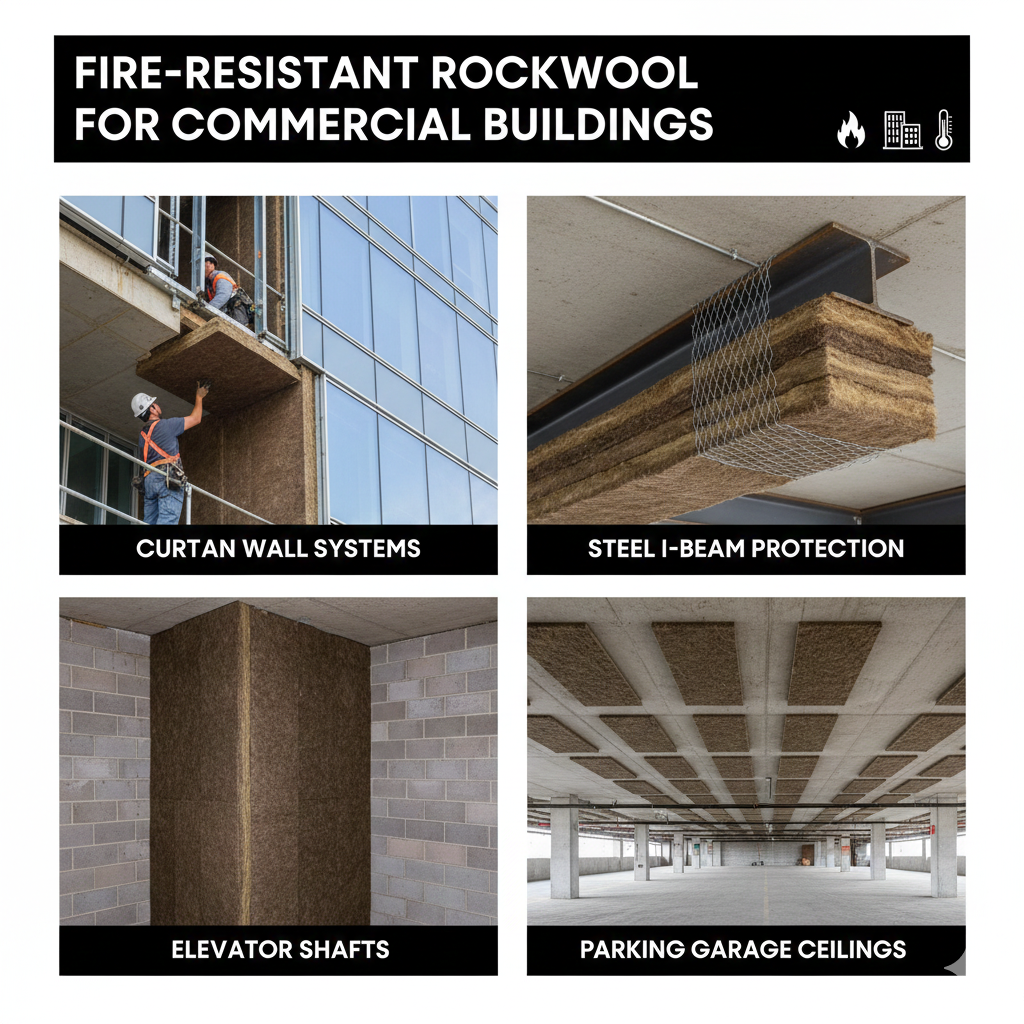

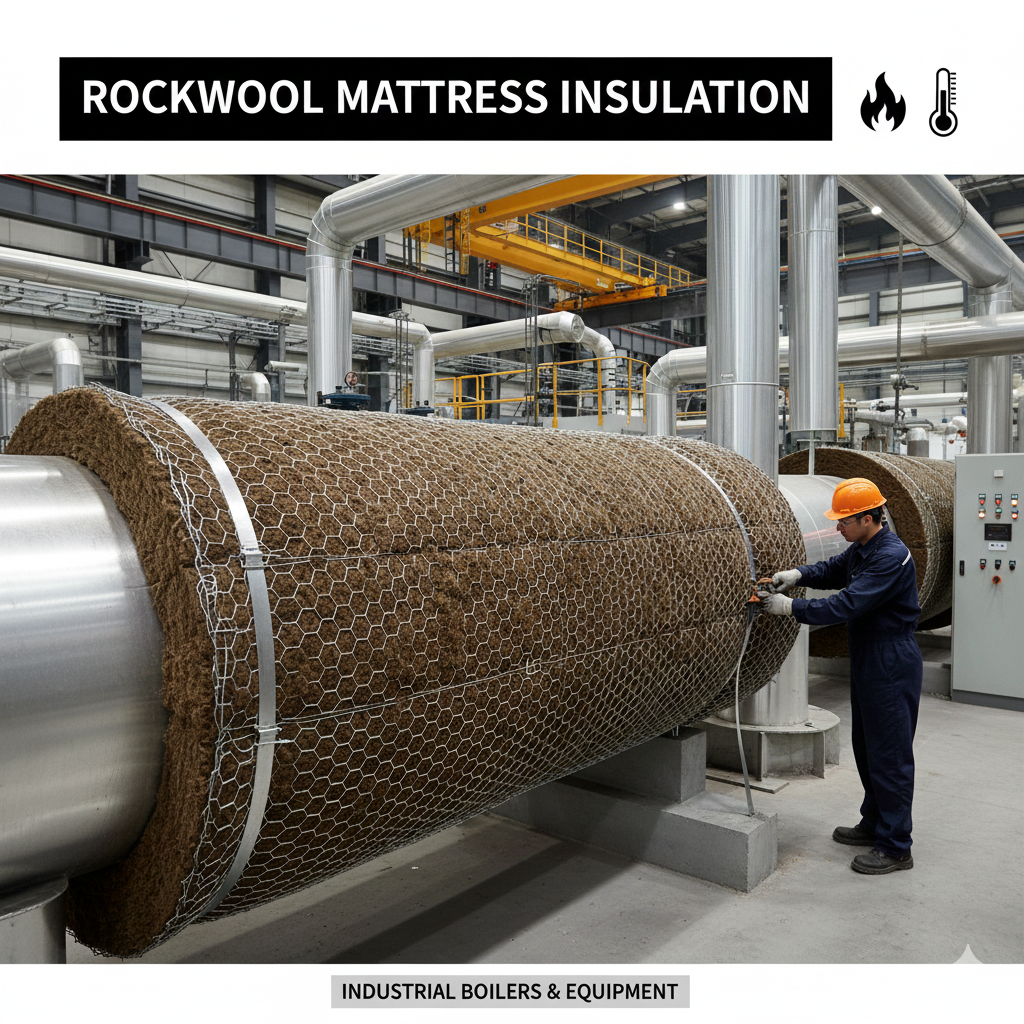

Fireproof Insulation Rockwool – Industry Standard

Rockwool is one of the most trusted fire-resistant insulation materials worldwide.

Key Advantages

- Non-combustible mineral fibers

- Maintains stability at extremely high temperatures

- Excellent for fireproof insulation for walls

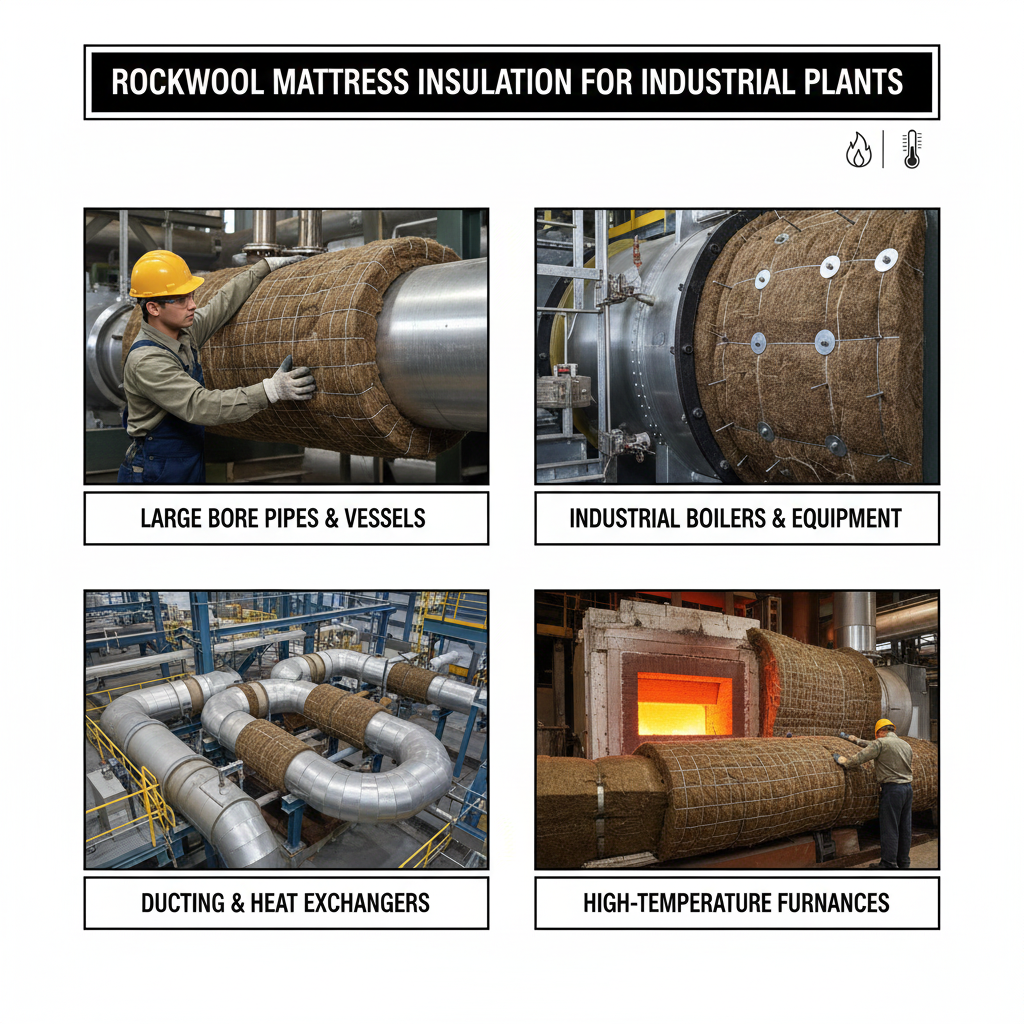

Rockwool is widely used in:

- Power plants

- Industrial sheds

- High-rise commercial buildings

Because of its performance, fireproof insulation rockwool is often chosen where fire safety is the top priority.

Fireproof Insulation Boards for Structural Protection

Fireproof insulation boards are rigid panels designed to protect walls, ceilings, and partitions.

Why Use Fireproof Insulation Board?

- Provides uniform fire resistance

- Easy to install in commercial interiors

- Ideal for shafts, stairwells, and service ducts

These boards are frequently combined with steel framing to create fire-resistant assemblies in offices and malls.

Fireproof Sheets for Kitchen & High-Heat Areas

Commercial kitchens are among the highest fire-risk zones.

Where Fireproof Sheets Are Used

- Behind cooking ranges

- Exhaust duct enclosures

- Utility walls

Using fireproof sheets for kitchen areas helps contain flames, reduce surface ignition, and improve overall fire safety compliance.

Thermal Performance & Fire Safety Together

Modern commercial insulation must balance heat control and fire resistance.

While evaluating options, many buyers also compare thermal insulation sheet price in Pakistan to understand cost vs. performance. Fireproof materials may have a higher upfront cost, but they offer long-term safety and compliance benefits.

How to Choose the Right Fireproof Insulation

When selecting insulation for commercial use, consider:

- Required fire rating (1 hour or 2 hour)

- Area of application (walls, kitchens, ceilings)

- Exposure to moisture or chemicals

- Installation method and durability

Not all insulation boards are equal—always prioritize certified fire-resistant systems.

Applications Across Commercial Sectors

Fireproof insulation is widely used in:

- Factories and warehouses

- Hospitals and laboratories

- Hotels and shopping malls

- Data centers and electrical rooms

Each environment has unique fire safety needs, making correct material selection essential.

Final Thoughts

Choosing the best fireproof insulation sheets for commercial use in Pakistan is a strategic investment in safety, compliance, and durability. Whether using rockwool, fireproof insulation boards, or specialized kitchen fireproof sheets, the right solution minimizes risk and enhances building performance.

Fire safety is not just about meeting codes—it’s about protecting people and property.

FAQ’S

Rockwool insulation is widely considered the best option for commercial buildings because it is non-combustible, offers high fire resistance, and performs well in walls, ceilings, and partitions.

1 hour fire rated insulation delays fire spread for a shorter duration and is suitable for internal partitions, while 2 hour fire rated insulation provides extended protection for high-risk commercial areas such as factories and stairwells.

Yes, most fireproof insulation materials also offer thermal control. Rockwool and fireproof insulation boards help reduce heat transfer while maintaining fire resistance.

Fireproof sheets for kitchen use are specifically designed to withstand high temperatures and are commonly installed behind cooking equipment and exhaust systems.

While requirements vary by building type, fireproof insulation is often mandatory to meet safety regulations, insurance standards, and fire protection guidelines.