Industrial plants operate under extreme conditions involving high temperatures, heavy machinery, continuous operation, and strict safety requirements. Insulation materials used in such environments must deliver thermal stability, fire resistance, and long-term durability. Rockwool mattress insulation for industrial plants is widely used because it meets these demanding performance standards.

This guide explains how rockwool mattresses work, their specifications, density options, pricing considerations, and availability in Pakistan.

What Is Rockwool Mattress Insulation?

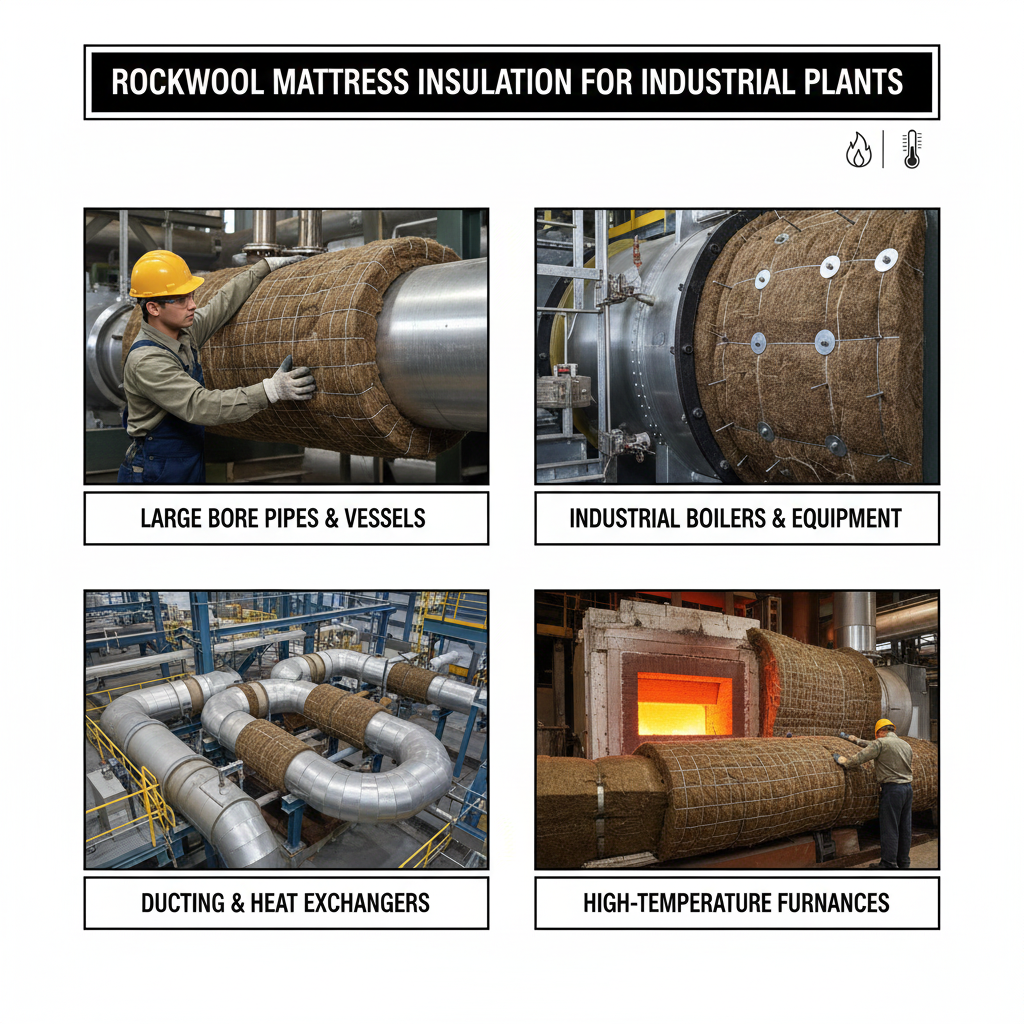

Rockwool mattress insulation is a flexible form of mineral insulation made from melted natural stone fibers. Unlike rigid boards, mattresses are designed to wrap around pipes, boilers, ducts, vessels, and industrial equipment.

Due to the inherent properties of rockwool material, these mattresses offer excellent resistance to heat, fire, and mechanical stress in industrial environments.

Why Industrial Plants Require Specialized Insulation

Industrial facilities face challenges such as:

- Continuous high-temperature exposure

- Fire risk around equipment and pipelines

- Energy loss from uninsulated surfaces

- Safety compliance requirements

Rockwool insulation addresses these issues while maintaining performance over long operational cycles.

Fire Safety in Industrial Environments

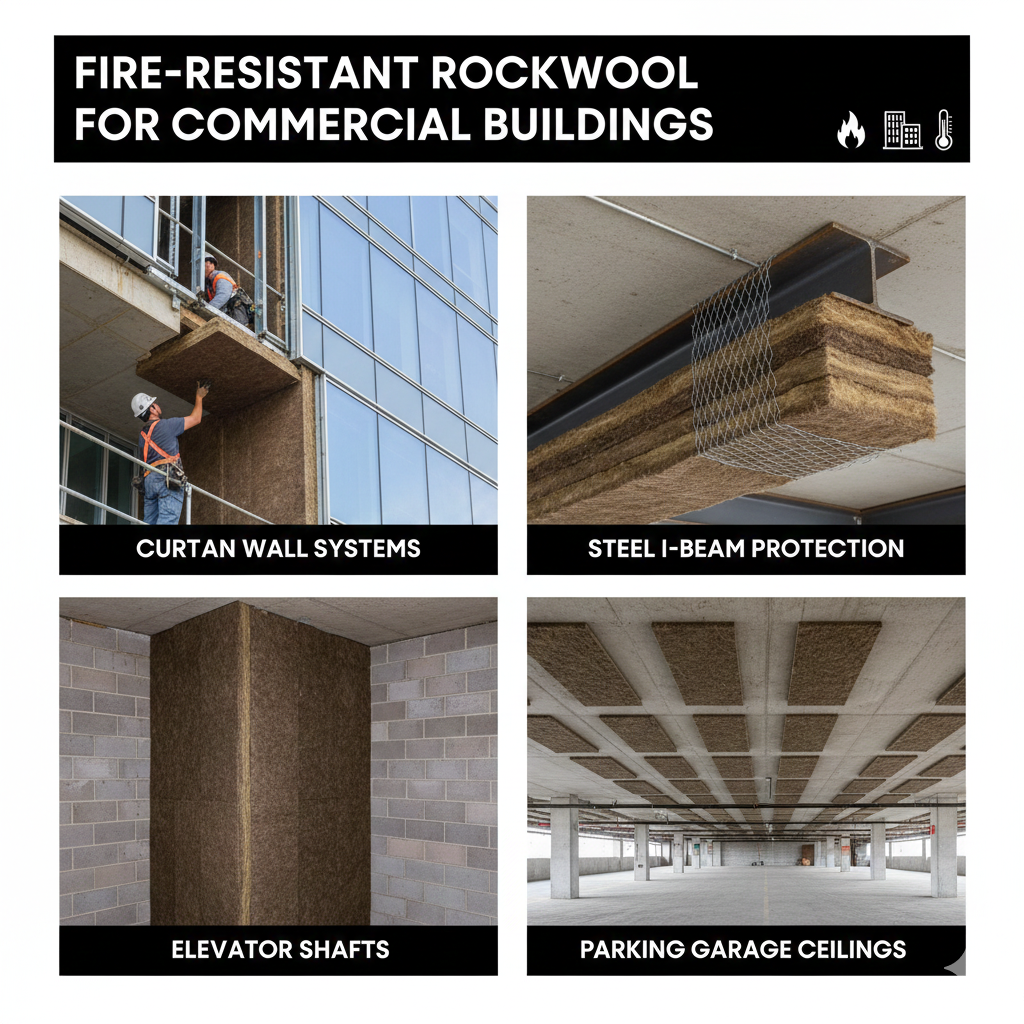

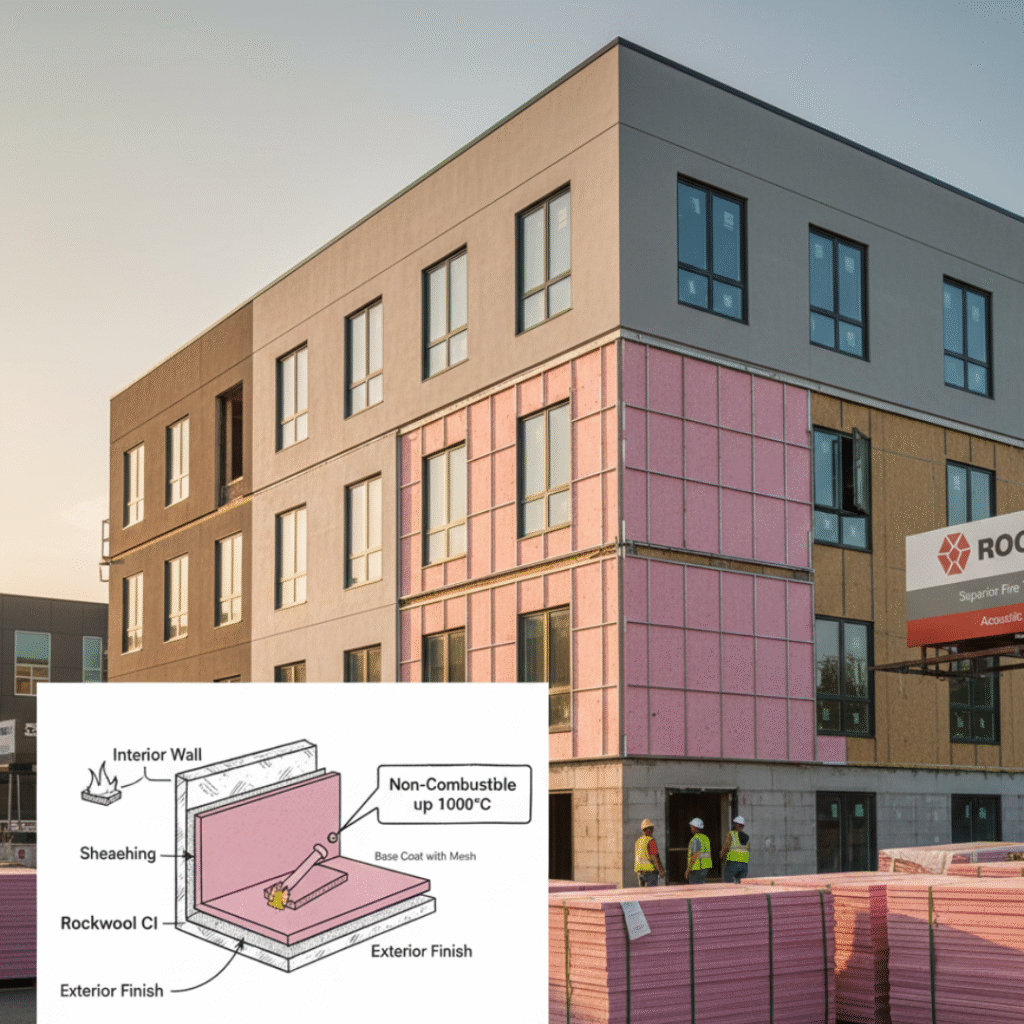

Although this guide focuses on industrial use, the same fire-resistant properties found in Fire Resistant Rockwool for Commercial Buildings apply to industrial plants. Rockwool does not burn, melt, or emit toxic fumes when exposed to fire, making it suitable for high-risk zones.

This characteristic significantly reduces fire spread in processing plants and energy facilities.

Rockwool Thermal Insulation Performance

Rockwool thermal insulation minimizes heat transfer by trapping air within its dense fiber network. In industrial plants, this helps:

- Maintain process temperatures

- Reduce heat loss from equipment

- Improve energy efficiency

- Protect workers from hot surfaces

Thermal performance remains stable even under fluctuating operating conditions.

Rockwool Insulation Specification for Industrial Use

A clear rockwool insulation specification is essential when selecting materials for industrial projects. Typical specifications include:

- Density range based on application

- Operating temperature tolerance

- Fire resistance classification

- Moisture resistance

- Mechanical strength

Correct specification ensures safety, efficiency, and compliance with engineering standards.

Understanding Rockwool Density Chart

A rockwool density chart helps engineers select the right product for specific industrial applications. Density affects insulation strength, thermal resistance, and durability.

Lower densities are used for general thermal insulation, while higher densities provide better mechanical stability for demanding conditions.

Rockwool Density 100kg/m³ – Industrial Standard

Rockwool density 100kg/m³ is commonly used in industrial plants where higher strength and heat resistance are required. This density provides:

- Excellent shape retention

- Strong thermal insulation

- Enhanced fire resistance

- Long service life

However, it is suitable for pipes, boilers, reactors, and high-temperature equipment.

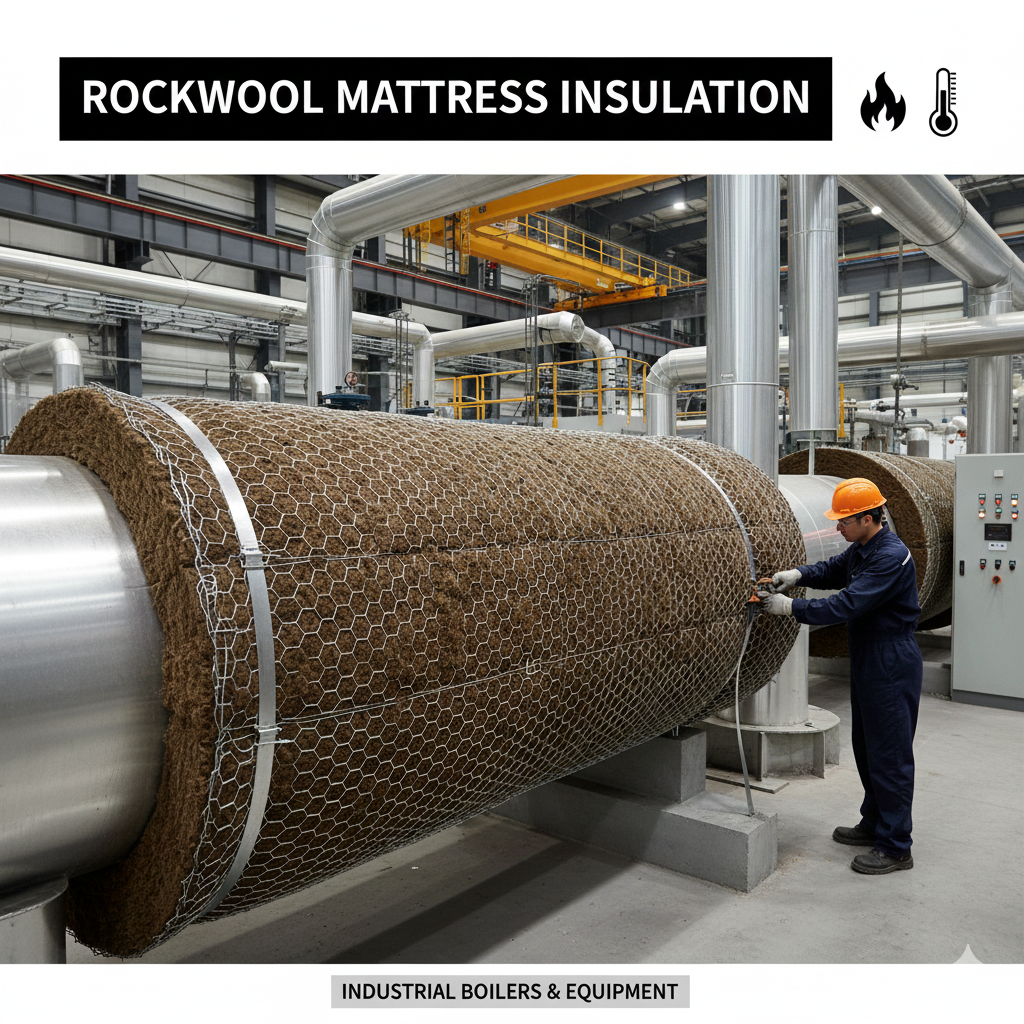

Rockwool Wired Mat for Industrial Equipment

A rockwool wired mat is a reinforced insulation mattress stitched with galvanized wire mesh. Moreover, this design improves strength and makes installation easier on curved or vibrating surfaces.

Wired mats are widely used for:

- Large diameter pipelines

- Industrial boilers

- Exhaust systems

- High-temperature vessels

Rockwool Board vs Mattress Insulation

While a rockwool board is ideal for flat surfaces like walls and ceilings, mattress insulation is preferred for industrial equipment due to its flexibility. Both forms are often used together in large industrial projects.

Rockwool Insulation Pakistan – Industrial Market Overview

The demand for rockwool insulation Pakistan has grown with the expansion of industrial zones, power plants, and manufacturing facilities. Rockwool is now a standard insulation choice in industries such as oil & gas, textile, chemical processing, and power generation.

Rockwool Manufacturers in Pakistan

Several suppliers operate as rockwool manufacturers in Pakistan, offering mattresses, boards, and wired mats. Reliable manufacturers ensure consistent density, accurate specifications, and quality control suitable for industrial use. However, selecting the right supplier is critical for long-term performance and safety compliance.

Rock Wool Insulation Price in Industrial Projects

The rock wool insulation price for industrial applications varies based on:

- Density and thickness

- Mattress or wired mat construction

- Temperature rating

- Quantity and project size

While the initial cost may be higher than basic insulation, rockwool delivers long-term savings through durability and energy efficiency.

Comparison with Thermal Insulation Sheet Price in Pakistan

When comparing industrial materials, the thermal insulation sheet price in Pakistan may seem lower for alternatives such as EPS or glasswool. However, these materials often lack the fire resistance and mechanical strength required in industrial plants.

Moreover, Rockwool remains the preferred choice where safety and performance are critical.

Use in Commercial-Industrial Hybrid Projects

In facilities that combine production and office spaces, rockwool is often specified for both industrial equipment and office areas. This overlaps with rockwool for commercial buildings in Pakistan, ensuring consistent fire safety and thermal control throughout the facility.

Final Thoughts on Rockwool Mattress Insulation for Industrial Plants

Rockwool mattress insulation is a reliable solution for industrial plants requiring fire safety, thermal efficiency, and mechanical durability. With proper specification, correct density selection, and quality installation, rockwool supports safe and efficient industrial operations for decades.

However, Its proven performance makes it one of the most trusted insulation materials in Pakistan’s industrial sector.

FAQ’S

Rockwool mattress insulation is flexible, fire-resistant, and thermally efficient, making it ideal for high-temperature pipes, boilers, and equipment in industrial plants. It ensures energy efficiency and safety compliance.

Rockwool density 100kg/m³ is commonly used in industrial plants because it provides excellent thermal insulation, mechanical strength, and fire resistance for equipment and pipelines.

A rockwool wired mat includes a galvanized wire mesh for added strength and easier installation on curved or vibrating surfaces. It is ideal for large pipes, boilers, and high-temperature industrial vessels.

You can source rockwool insulation Pakistan from certified distributors or rockwool manufacturers in Pakistan who supply boards, mattresses, and wired mats with verified specifications and quality control.