Fire safety has become a critical requirement for residential, commercial, and industrial buildings in Pakistan. One of the most trusted solutions for passive fire protection is rockwool insulation, also known as mineral wool. Selecting the best density rockwool for fireproofing plays a major role in achieving fire resistance, thermal stability, and long-term building safety.

This detailed guide explains rockwool densities, fire ratings, applications, pricing considerations, and comparisons to help you choose the right solution for your project.

What Is Rockwool Insulation?

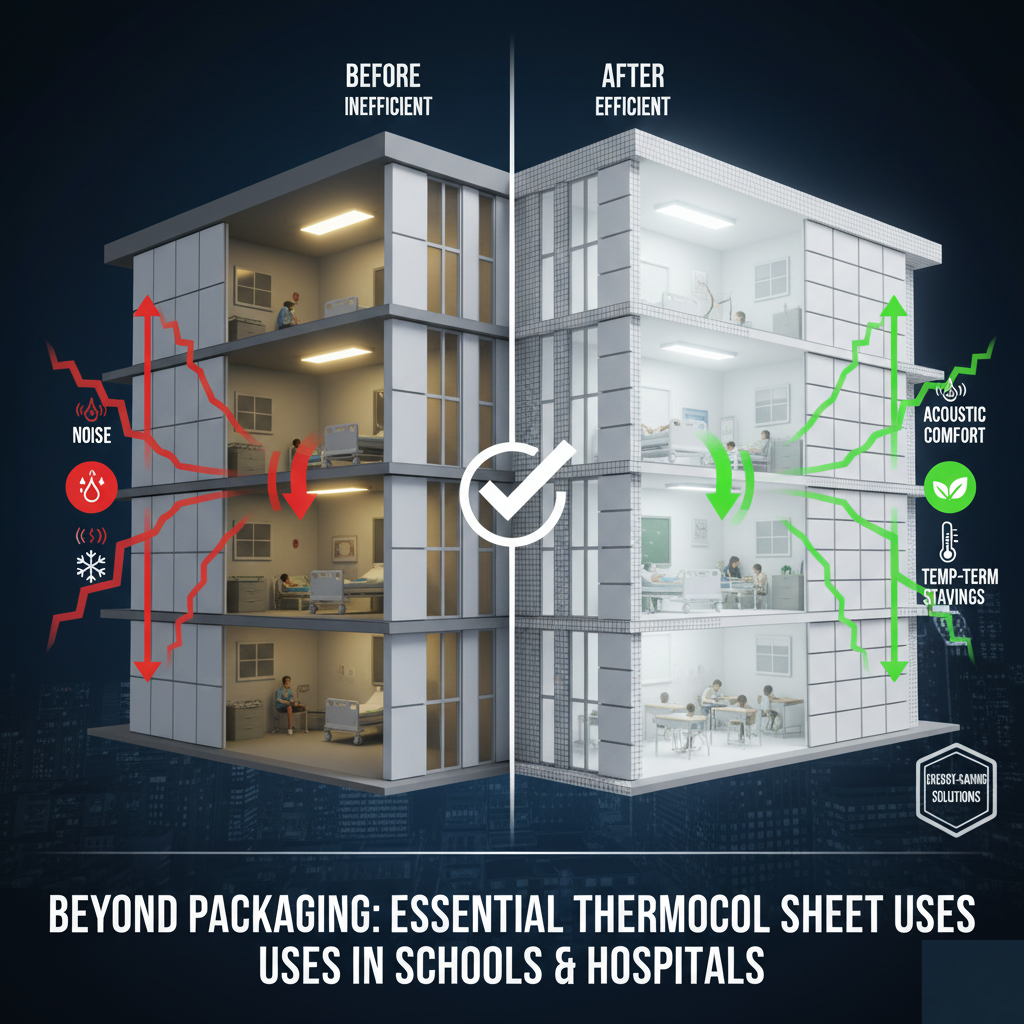

Rockwool insulation is manufactured from natural volcanic rock and minerals that are melted and spun into dense, fibrous insulation. Because of its non-combustible nature, rockwool insulation Pakistan is widely used in buildings that require high fire resistance along with thermal and acoustic performance.

Unlike many synthetic materials, rockwool does not melt or emit toxic smoke at high temperatures, making it ideal for fireproofing applications.

Why Density Matters in Fireproofing

Density directly affects how rockwool performs under fire exposure. Higher-density boards offer better structural integrity, slower heat transfer, and longer fire resistance times.

For fireproofing applications:

- Low density is suitable for basic thermal or acoustic insulation

- Medium density balances insulation and cost

- High density is preferred for certified fire-rated systems

Choosing the correct density ensures compliance with safety standards without unnecessary overspending.

Best Density Rockwool for Fireproofing Applications

1. Medium Density Rockwool (40–60 kg/m³)

This range is commonly used for:

- Internal partition walls

- Ceiling fire barriers

- HVAC and service shafts

It provides reliable thermal insulation and basic fire protection in non-critical areas.

2. High Density Rockwool (80–120 kg/m³)

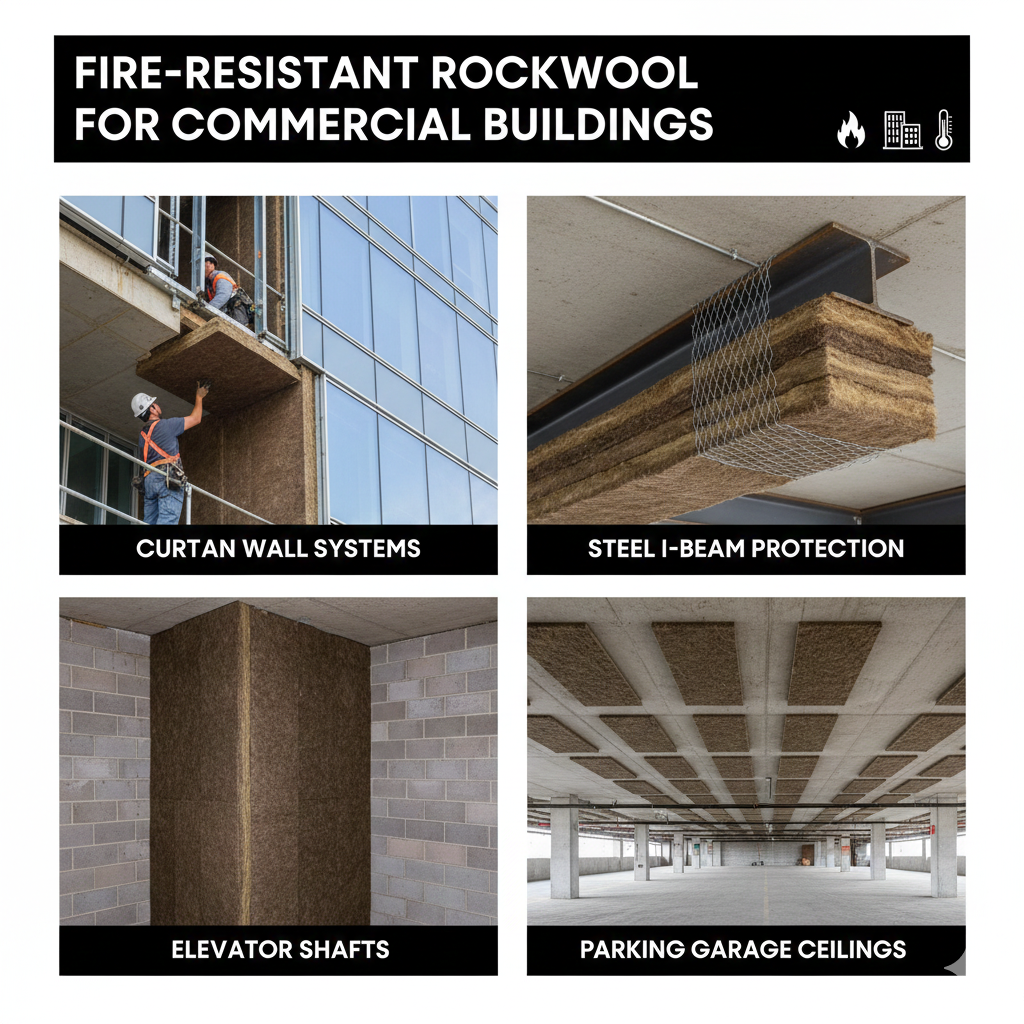

High-density rockwool is considered the best density rockwool for fireproofing in demanding environments, such as:

- Fire-rated walls and floors

- Industrial plants and warehouses

- High-rise buildings

These densities are often used in systems achieving mineral wool 2 hour fire rating when installed correctly.

Mineral Wool 2 Hour Fire Rating – How It Works

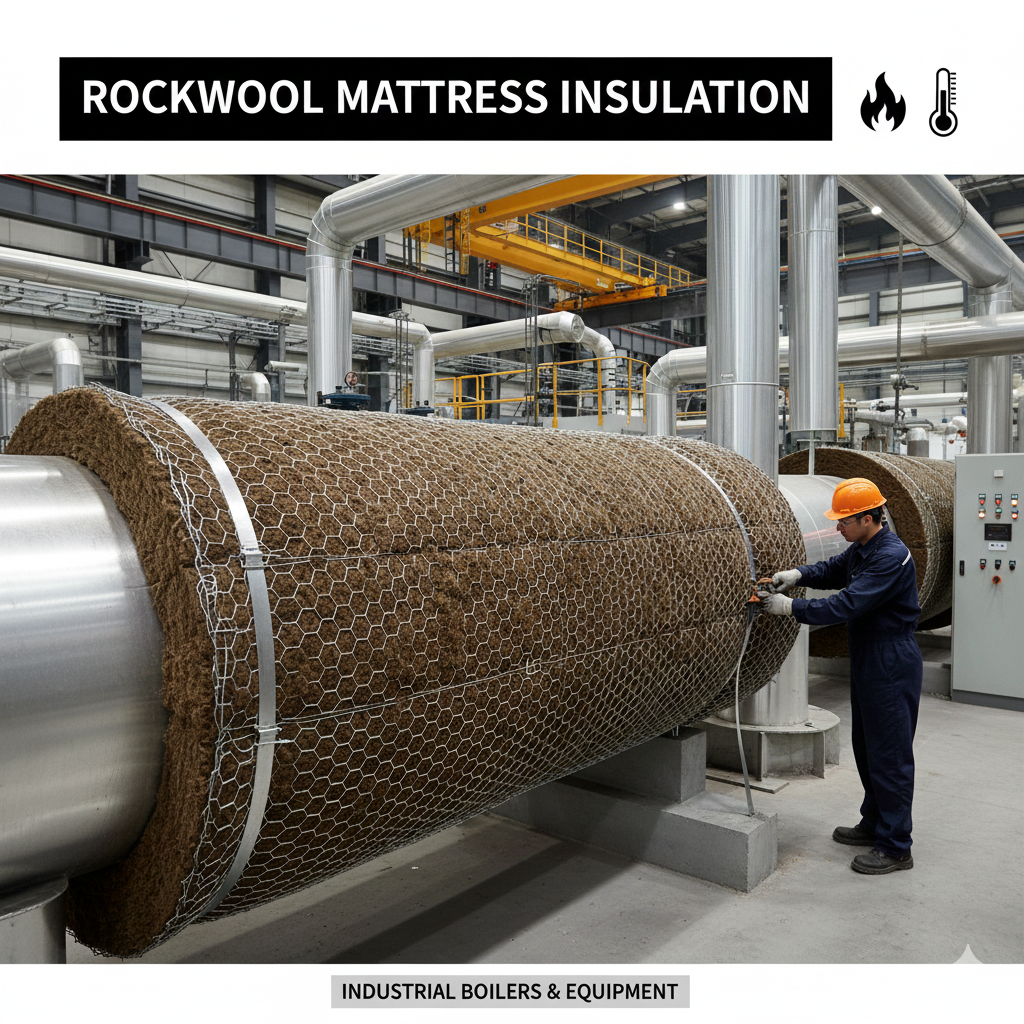

Rockwool fibers can withstand temperatures above 1000°C. When installed in tested assemblies, high-density rockwool can help achieve a mineral wool 2 hour fire rating, meaning it can resist fire spread for up to two hours.

This makes it suitable for:

- Fire escape routes

- Electrical rooms

- Structural steel fire protection

Fire ratings depend on system design, thickness, and installation quality.

Faced Rockwool Insulation for Fireproofing

Faced rockwool insulation includes an additional facing layer such as aluminium foil, black tissue, or fiberglass mesh. These facings:

- Improve handling and durability

- Reduce fiber release

- Enhance moisture resistance

Faced boards are commonly used in duct fireproofing, ceilings, and industrial applications where surface protection is required.

Is Rockwool Insulation Waterproof?

A common question is whether rockwool insulation waterproof performance is reliable. Rockwool fibers are water-repellent but breathable, meaning:

- They do not absorb water easily

- They retain shape and fire performance after drying

However, proper vapor barriers and external protection are recommended for exposed installations.

Rockwool Insulation Small Pack – When Is It Useful?

For minor projects or repairs, rockwool insulation small pack options are available. These are suitable for:

- Small rooms or partitions

- Generator enclosures

- Home studios and fire-rated cabinets

Small packs reduce waste and are cost-effective for limited applications.

Rockwool vs Fibreglass for Fireproofing

The comparison of rockwool vs fibreglass is important when fire safety is a priority:

- Rockwool is non-combustible and offers higher fire resistance

- Fibreglass provides thermal insulation but lower fire performance

- Rockwool maintains structure at extreme temperatures

For fireproofing, rockwool is generally the safer and more durable option.

Density Comparison Table for Fireproofing Rockwool

| Density (kg/m³) | Fire Resistance Level | Common Applications | Recommended Use |

|---|---|---|---|

| 40–60 | Low | Thermal insulation | Not suitable for fireproofing |

| 60–80 | Medium | Acoustic panels | Limited fire protection |

| 80–100 | High | Fire-rated walls, ceilings | Ideal for commercial fireproofing |

| 100–120 | Very High | Steel structures, shafts | Best density rockwool for fireproofing |

Rockwool Insulation Price in Pakistan – What Affects Cost?

The rockwool insulation price depends on:

- Density and thickness

- Faced or unfaced boards

- Brand and quality standards

- Quantity and location

In the local market, rockwool insulation Pakistan pricing varies by city and application, but higher-density boards naturally cost more due to improved fire performance.

Common Fireproofing Applications of Rockwool

Rockwool is widely used for:

- Fire-rated walls and partitions

- Steel structure fire protection

- Generator and boiler rooms

- Industrial sheds and factories

- Commercial buildings and hospitals

Its versatility makes it a preferred fireproofing solution across Pakistan.

Conclusion

Selecting the best density rockwool for fireproofing is essential for building safety, compliance, and long-term performance. Medium-density rockwool works well for standard applications, while high-density boards are ideal for achieving advanced fire ratings such as mineral wool 2 hour fire rating. With added benefits like moisture resistance, acoustic insulation, and durability, rockwool remains one of the most reliable fireproofing materials available.

FAQ’S

The ideal density ranges from 80 to 120 kg/m³, depending on the level of fire resistance required and the application area.

Yes, rockwool insulation Pakistan is widely used in commercial, industrial, and residential projects due to its excellent fire and thermal properties.

When installed as part of a certified system, high-density mineral wool can achieve a mineral wool 2 hour fire rating.

Rockwool is water-repellent and maintains its insulation and fire resistance even in humid or damp conditions.

In a rockwool vs fibreglass comparison, rockwool offers significantly higher fire resistance and does not melt under extreme heat.