Sandwich panels have become a core building solution for industrial, commercial, and prefabricated structures due to their speed of installation, thermal performance, and structural efficiency. When combined with EPS or Rockwool insulation, these panels deliver reliable heat control, fire resistance, and long-term durability.

Moreover, this guide explains how EPS and Rockwool sandwich panels work, their applications, cost considerations, and how to choose the right panel type for your project.

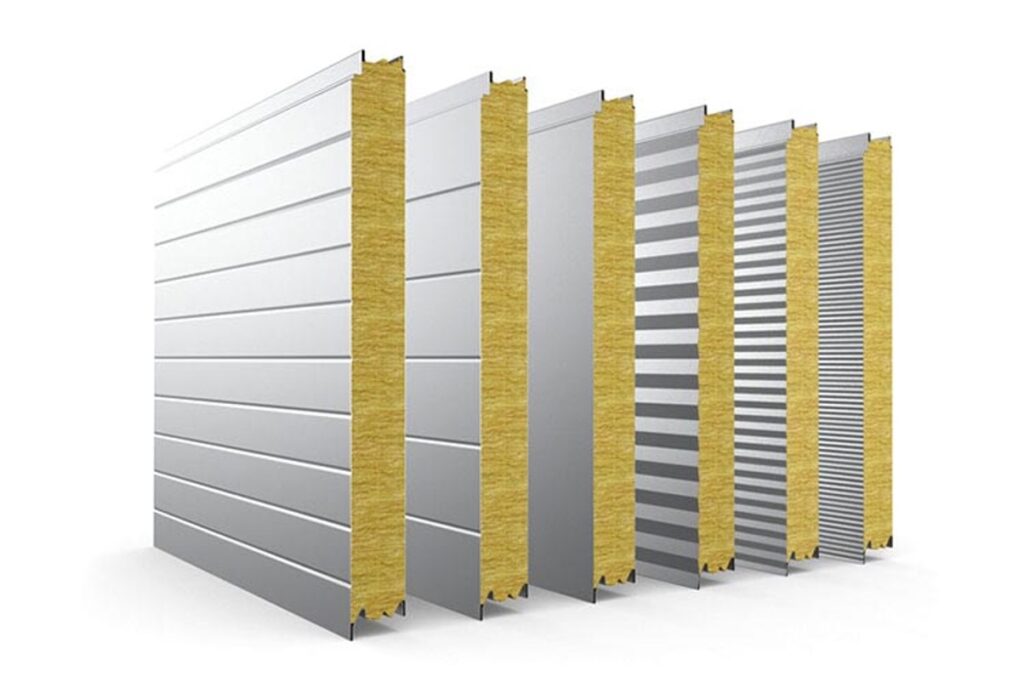

What Are Insulated Sandwich Panels?

Insulated sandwich panels are prefabricated building elements made of three layers:

- An outer metal sheet

- An insulation core (EPS or Rockwool)

- An inner metal sheet

Moreover, this layered design provides thermal insulation, sound reduction, and structural rigidity in a single product, making them ideal for fast-track construction projects.

EPS Sandwich Panels – Lightweight & Cost-Effective

EPS-based panels are widely used where thermal insulation and affordability are the primary requirements. Expanded polystyrene cores make panels light in weight while maintaining good insulation properties.

EPS sandwich panels are commonly selected for:

- Warehouses

- Cold storage units

- Prefabricated offices

- Temporary structures

Moreover, they are easy to handle and reduce overall construction load.

Rockwool Sandwich Panels – Fire & Sound Protection

Rockwool metal panels are designed for applications where fire safety and acoustic insulation are critical. It is a mineral-based insulation material that offers excellent resistance to high temperatures.

Moreover, they are ideal for:

- Industrial plants

- Power facilities

- Commercial kitchens

- Fire-rated buildings

However, their dense core improves sound absorption and enhances safety compliance.

EPS vs Rockwool Sandwich Panels – Key Differences

| Feature | EPS Panels | Rockwool Panels |

|---|---|---|

| Weight | Lightweight | Heavier |

| Fire Resistance | Moderate | Excellent |

| Thermal Insulation | Good | Very Good |

| Sound Insulation | Limited | High |

| Cost | Lower | Higher |

However, choosing the right insulation core depends on project requirements rather than price alone.

Bredco Sandwich Panels – What to Know

Bredco sandwich panels are known in the market for standardized panel systems used in modular and industrial construction. These panels typically offer consistent thickness, reliable bonding, and compatibility with EPS or Rockwool cores.

Builders often consider bredco panels when looking for prefabricated solutions that balance performance and installation speed.

BRD Insulation Panels for Sale – Market Overview

You may find brd insulation panels for sale through local suppliers and distributors offering EPS and Rockwool core options. Availability usually depends on panel thickness, metal gauge, and insulation density.

Furthermore, projects requiring bulk quantities often benefit from factory-direct sourcing to maintain consistency and reduce lead time.

PU Rockwool Panels – Hybrid Insulation Systems

PU rockwool panels combine polyurethane performance with mineral insulation benefits. These systems are typically used in high-spec commercial or industrial environments where thermal efficiency and fire resistance must coexist.

Such panels are more specialized and are selected based on engineering specifications rather than general construction needs.

EPS vs Rockwool Sandwich Panels – Price Comparison (Pakistan)

Prices vary by thickness, metal sheet gauge, fire rating, and order volume. The table below reflects typical market ranges.

| Panel Type | Insulation Core | Thickness | Approx. Price Range (PKR / sq.ft) | Best Use |

|---|---|---|---|---|

| Sandwich Panel | EPS | 50mm | 650 – 900 | Warehouses, prefab offices |

| Sandwich Panel | EPS | 75mm | 900 – 1,200 | Cold rooms, site offices |

| Sandwich Panel | Rockwool | 50mm | 1,300 – 1,700 | Fire-rated buildings |

| Sandwich Panel | Rockwool | 75mm | 1,700 – 2,200 | Industrial & commercial units |

| PU Rockwool Panel | Hybrid | 50mm | 2,200 – 2,800 | High-spec facilities |

Cost Insight:

EPS panels remain the most economical option, while Rockwool and PU Rockwool panels are selected for fire safety, acoustic control, and regulatory compliance.

BRD Insulation Panels Cost & Budget Planning

Understanding brd insulation panels cost helps developers plan efficiently. Moreover, pricing is influenced by:

- Insulation core type (EPS or Rockwool)

- Panel thickness

- Metal sheet gauge

- Fire rating requirements

Moreover, EPS panels are usually more economical, while Rockwool panels command higher prices due to material density and safety performance.

Sandwich Panels for Cost Optimization

When evaluating sandwich panels for cost, consider total lifecycle value instead of upfront pricing. Moreover, faster installation, reduced energy loss, and minimal maintenance can significantly lower long-term expenses.

However, cost-efficient planning includes selecting the right insulation core for the building’s actual functional needs

Where Are EPS & Rockwool Sandwich Panels Used?

These panels are widely used in:

- Factories and industrial sheds

- Cold storage and clean rooms

- Commercial buildings

- Prefabricated housing

- Controlled-environment facilities

However, their versatility makes them suitable for both temporary and permanent structures.

How to Choose the Right Sandwich Panel

Choose EPS sandwich panels if:

- Budget is a priority

- Fire rating is not critical

- Lightweight construction is required

Choose Rockwool sandwich panels if:

- Fire safety is mandatory

- Acoustic control is required

- The building is industrial or high-risk

Moreover, always consult structural and fire safety guidelines before final selection.

Final Thoughts

Sandwich panels using EPS and Rockwool offer modern construction solutions that combine speed, insulation performance, and structural integrity. Whether selecting EPS for economical builds or Rockwool for fire-rated applications, the right choice enhances efficiency and safety.

However, understanding material behavior, cost structure, and application ensures long-term value for any construction project.

FAQ’S

Insulated sandwich panels are used in industrial, commercial, and prefabricated buildings to provide thermal insulation, structural strength, and faster construction.

EPS panels are better for cost-effective thermal insulation, while Rockwool panels are preferred for fire resistance and sound insulation in commercial and industrial projects.

Yes, bredco sandwich panels are commonly used in industrial structures due to their standardized design, durability, and compatibility with EPS or Rockwool insulation cores.

Sandwich panels for cost are calculated based on insulation core type, thickness, metal sheet gauge, fire rating, and total order quantity.

Yes, brd insulation panels for sale are available through local manufacturers and distributors offering EPS, Rockwool, and hybrid insulation options.

Yes, rockwool metal panels offer excellent fire resistance and are widely used in fire-rated commercial and industrial buildings.