Sandwich panels have become one of the most demanded construction materials in Pakistan due to their insulation efficiency, fast installation, and cost control. From warehouses and factories to cold rooms and prefab buildings, understanding the Sandwich Panels Price Comparison in Pakistan helps buyers choose the right panel without overspending.

This guide breaks down prices, types, city-wise trends, and key factors affecting cost—so you can make a smart, future-proof decision.

What Are Sandwich Panels?

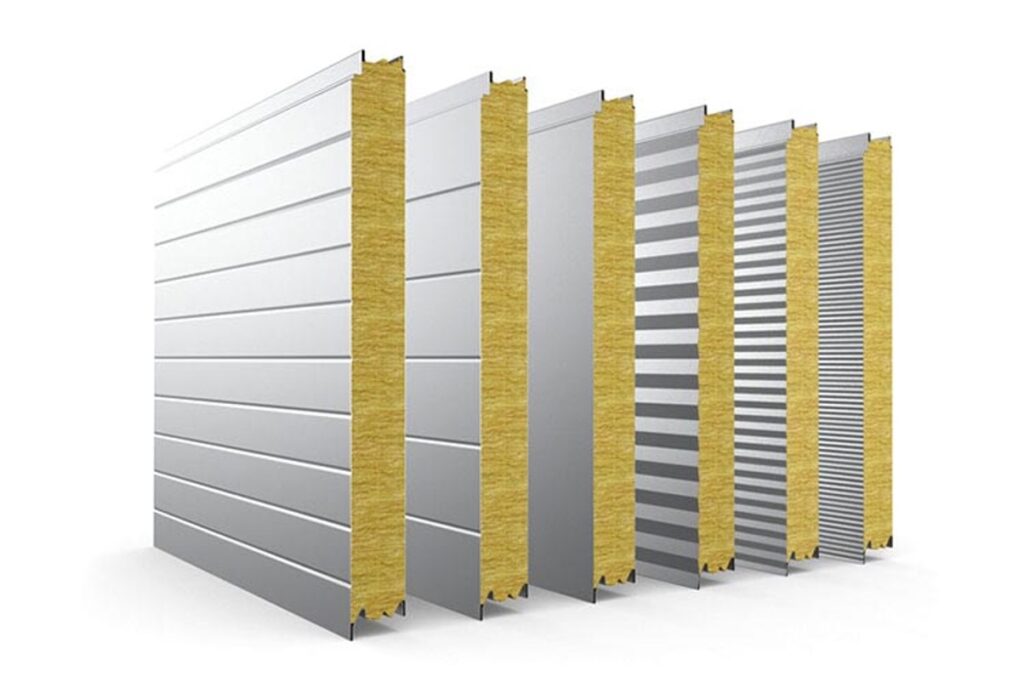

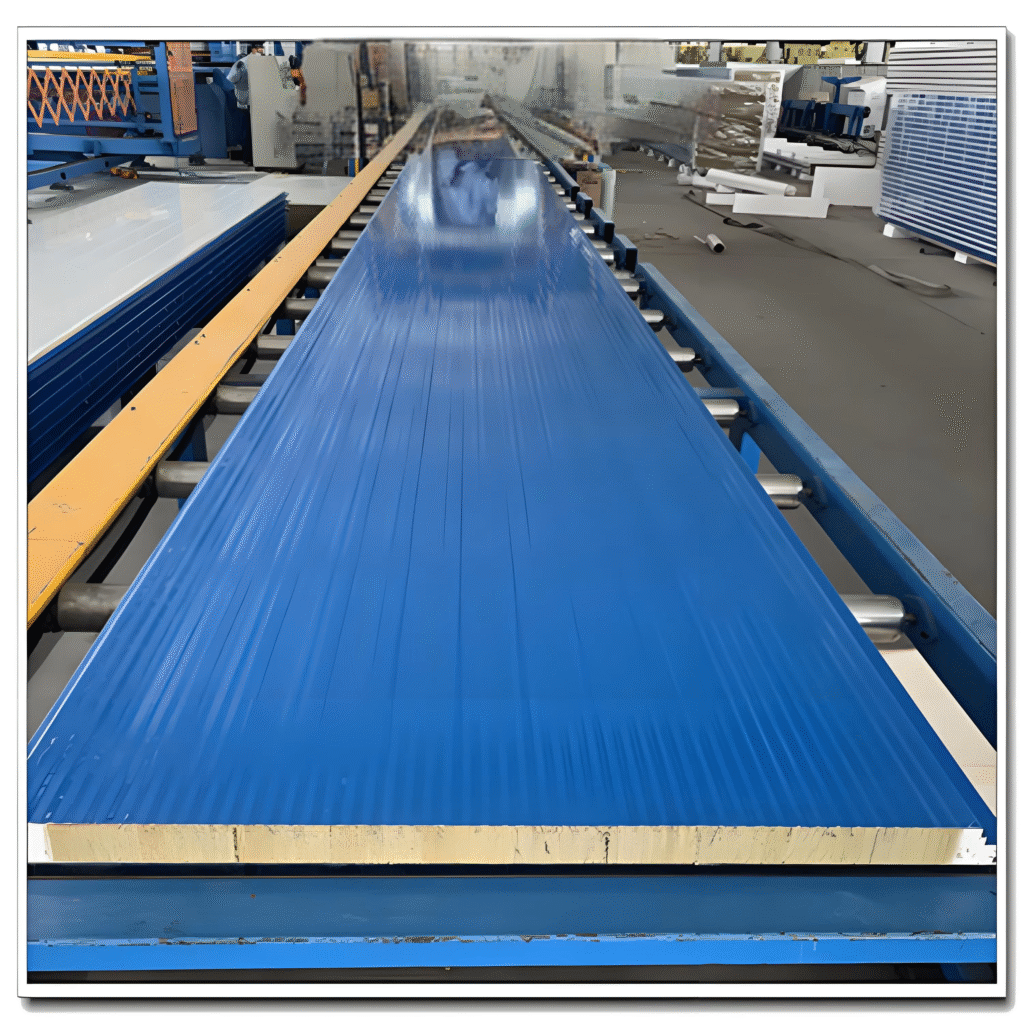

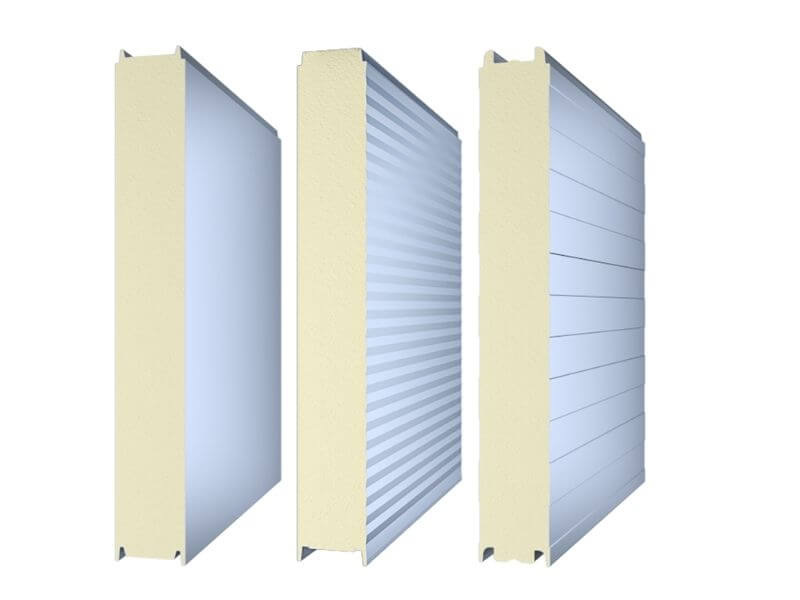

Sandwich panels are prefabricated building materials made of three layers:

- Two outer sheets (steel, PVC, or coated metal)

- One insulation core (EPS, PU, PIR, or mineral wool)

These panels offer thermal insulation, sound reduction, and structural stability in a single product, making them ideal for industrial and commercial projects.

Why Sandwich Panels Prices Vary in Pakistan

Sandwich panel prices are not fixed. Several variables influence the final cost:

- Type of insulation core

- Thickness of the panel

- Facing material (steel or PVC)

- City-based supply and logistics

- Project quantity and customization

Because of these variables, a proper sandwich panels price comparison is essential before purchasing.

Sandwich Panels Price Comparison in Pakistan

In general, sandwich panel prices in Pakistan fall into different brackets depending on application and material. Roof panels usually cost more than wall panels due to load-bearing requirements, while insulation core type significantly affects pricing.

This Sandwich Panels Price Comparison in Pakistan helps buyers understand why prices differ rather than focusing on the cheapest option.

Sandwich Panels Price Comparison Table (Pakistan)

Prices are indicative market ranges and may vary by thickness, coating, and city.

| Sandwich Panel Type | Common Thickness | Typical Use | Price Range (PKR / sq.ft) |

|---|---|---|---|

| EPS Sandwich Panels | 50–75 mm | Warehouses, site offices | 950 – 1,350 |

| EPS Roof Panels | 50–100 mm | Industrial roofing | 1,200 – 1,700 |

| Steel Sandwich Panels | 50–100 mm | Factories, sheds | 1,600 – 2,400 |

| PVC Sandwich Panels | 25–50 mm | Clean rooms, interiors | 1,300 – 1,900 |

| 4×8 Sandwich Panels | 50 mm | Prefab structures | 1,100 – 1,600 |

| Roof Sandwich Panels (Heavy Duty) | 75–100 mm | Temperature control | 1,800 – 2,800 |

EPS Sandwich Panel Price Comparison

EPS panels are the most widely used option due to affordability and decent insulation.

Key Features:

- Lightweight

- Cost-effective

- Suitable for warehouses and site offices

The EPS sandwich panel price comparison shows that EPS remains the best choice for budget-focused projects, especially where moderate temperature control is required.

Steel Sandwich Panels Price in Lahore

Lahore is a major industrial hub, so demand for heavy-duty panels is high.

The steel sandwich panels price in Lahore is influenced by steel sheet thickness and coating quality.

Steel panels are preferred for:

- Industrial sheds

- Manufacturing plants

- Long-span roofing systems

Prices in Lahore are often competitive due to higher supplier availability.

Roof Sandwich Panels Price in Pakistan

Roof panels are designed to handle heat, rain, and structural loads.

The roof sandwich panels price in Pakistan is generally higher than wall panels due to:

- Extra thickness

- Higher density insulation

- Stronger outer sheets

Roof sandwich panels are commonly used in temperature-sensitive warehouses and industrial units

PVC Sandwich Panels Price Comparison

PVC panels are mostly used for indoor applications and clean environments.

Advantages:

- Moisture resistance

- Easy maintenance

- Clean finish

The PVC sandwich panels price comparison places PVC panels slightly higher than EPS wall panels but lower than steel roof panels.

EPS vs Steel vs PVC – Cost Perspective

| Panel Type | Initial Cost | Durability | Best For |

|---|---|---|---|

| EPS | Low | Medium | Budget warehouses |

| Steel | High | Very High | Industrial buildings |

| PVC | Medium | Medium | Hygienic interiors |

This breakdown supports a more practical sandwich panels price comparison beyond just numbers.

4×8 Sandwich Panels Price Comparison

Standard sizing helps reduce installation waste.

The 4×8 sandwich panels price comparison is popular among small warehouse owners and prefab builders because it simplifies budgeting and transport.

Panels in this size are widely available and often more cost-efficient for medium-scale projects.

Sandwich Panel Price in Rawalpindi

Rawalpindi’s construction market caters heavily to warehouses and logistics units.

The sandwich panel price in Rawalpindi may vary slightly due to transportation costs and limited local manufacturing compared to Lahore.

However, Rawalpindi remains a strong market for EPS and roof panels.

Sandwich Panel Price in Islamabad

The sandwich panel price in Islamabad tends to be higher due to:

- Premium construction standards

- Customized project requirements

- Higher labor and logistics costs

Insulated panels in Islamabad are commonly used for commercial buildings and controlled environments.

Which Sandwich Panel Offers the Best Value?

Value does not always mean the lowest price. The right panel depends on usage:

- EPS panels → budget warehouses

- Steel sandwich panels → industrial strength

- Roof panels → temperature and weather control

- PVC panels → clean interiors

A proper sandwich panels price comparison ensures long-term savings instead of short-term cost cutting.

Common Mistakes Buyers Should Avoid

- Choosing panels only based on price

- Ignoring insulation thickness

- Not considering city-based cost variation

- Skipping installation quality

These mistakes often increase maintenance and energy costs over time.

Future Trend of Sandwich Panels in Pakistan

With rising energy costs and stricter building standards, insulated sandwich panels are expected to dominate industrial construction. Demand for EPS, steel, and roof panels will continue to rise across major cities.

Final Thoughts

Understanding Sandwich Panels Price Comparison in Pakistan helps buyers balance performance, durability, and budget. Whether you are comparing EPS options, roof systems, or city-wise prices, informed decisions always lead to better project outcomes.

If price clarity and insulation performance matter to your project, sandwich panels remain one of the smartest construction investments in Pakistan.

FAQ’S

Sandwich panel prices depend on insulation core type (EPS, PU, PVC), panel thickness, outer sheet material, quantity ordered, and city-wise transportation costs.

EPS panels are generally the most budget-friendly option. They provide decent thermal insulation and are widely used for warehouses and prefab buildings.

Yes, roof sandwich panels usually cost more because they require higher strength, thicker insulation, and better weather resistance compared to wall panels.

Prices in Lahore are often lower due to local manufacturing. Rawalpindi and Islamabad may have slightly higher rates because of logistics and premium construction requirements

Yes, standard sizes like 4×8 panels are usually more cost-effective as they reduce manufacturing waste and installation time.

Steel sandwich panels and EPS roof panels are commonly used for industrial warehouses due to their strength, durability, and thermal performance.

Yes, insulated sandwich panels reduce heat transfer, helping maintain indoor temperatures and lowering electricity consumption for cooling or heating.

With proper installation, sandwich panels can last 20–30 years, making them a long-term and cost-effective construction solution.