Why Insulating Your Water Tank is Non-Negotiable

A water tank—whether on your rooftop, in your loft, or part of a hot water system—is one of the most vital, yet often neglected, components of a residential or commercial property. Most people think of plumbing or heating elements, but rarely do they consider the material that surrounds the tank itself. In an era where energy costs are a major concern and sustainable living is a priority, leaving a water tank uninsulated is akin to leaving money on the table. This is where a simple, cost-effective, and highly efficient solution comes into play: Thermocol insulation for water tanks. Known scientifically as Expanded Polystyrene (EPS), this material offers a powerful thermal barrier that addresses one of the biggest sources of energy waste in a building.

The True Cost of an Uninsulated Tank

Without a proper thermal barrier, your tank is in constant thermal warfare with the surrounding environment.

- In Cold Climates: A cold water tank in an unheated loft can freeze, causing catastrophic pipe bursts. A hot water cylinder loses heat rapidly, forcing the water heater to cycle on more frequently and significantly increasing your utility bills. This constant heat loss is known as thermal bridging.

- In Hot Climates: A rooftop water storage tank absorbs relentless solar radiation, heating the water inside to uncomfortable temperatures that can even encourage bacterial growth. The water becomes too hot for a refreshing shower and requires energy-intensive cooling before use.

The solution is not just an expense; it is a long-term investment in energy efficiency and the longevity of your water system.

Thermocol (EPS): The Ideal Material for Water Tank Insulation

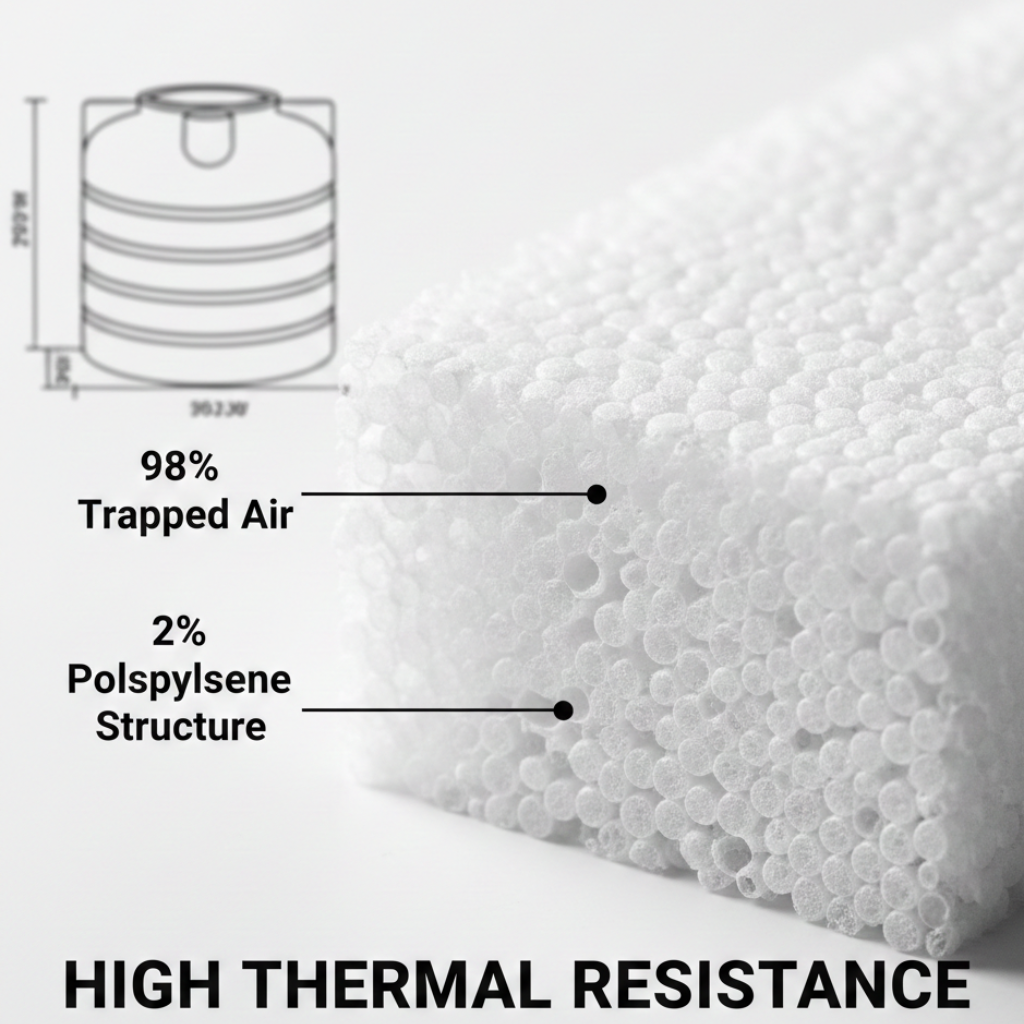

Thermocol, or Expanded Polystyrene (EPS), is a remarkably effective material for creating a robust thermal envelope around a water tank. Its unique structure is the key to its superior performance.

Understanding Expanded Polystyrene (EPS)

EPS is a lightweight, rigid foam plastic material composed of millions of tiny, closed cells. Amazingly, it is made up of about 98% trapped air and only 2% polystyrene material. It is these trapped air pockets that give it its extraordinary thermal resistance, acting as an excellent barrier against heat transfer.

Key Benefits of Using Thermocol Sheets

The properties of EPS make it an ideal choice when considering water tank insulation materials:

- High R-Value (Thermal Resistance): The R-value is the measure of an insulation material’s ability to resist heat flow. EPS foam boards offer a consistently good R-value per inch of thickness, ensuring your water temperature is maintained efficiently.

- Cost-Effectiveness: Compared to alternatives like Polyisocyanurate (PIR) or high-density spray foam, Thermocol insulation is generally more affordable insulation material upfront, providing a high return on investment quickly through energy savings.

- Lightweight and Easy to Handle: The low density of EPS makes the insulation sheets easy to cut, shape, and transport. This is a significant advantage for both professional installers and the DIY water tank insulation enthusiast.

- Moisture and Water Resistance: Unlike fibrous materials like fiberglass blankets, EPS is highly resistant to water absorption. This property prevents the material from becoming saturated, which would severely compromise its insulating properties and lead to mold or mildew growth. This is crucial for tanks where condensation or external moisture is a risk.

- Durability and Longevity: When properly installed and protected from direct UV light, EPS foam is robust and maintains its thermal performance for decades, offering a long-term insulation solution.

- Non-Toxic and Safe: Thermocol is non-toxic and does not emit harmful gases, making it safe for use in residential environments, even when placed near domestic water storage tanks.

Step-by-Step Guide to DIY Thermocol Insulation For Water Tanks

Insulating a water tank with Thermocol foam boards is a feasible DIY project that can be completed in a few hours. This method is particularly effective for rectangular or square cold water storage tanks typically found in lofts, or for standard hot water cylinders where a ready-made insulation jacket may not be sufficient.

Preparation and Measurement

- Safety First: If insulating a hot water cylinder, turn off the water supply and the power to the heating element (boiler or immersion heater). Allow the tank to cool slightly to ensure a safe working environment.

- Clean the Surface: The tank surface must be clean, dry, and free of dust, dirt, or grease. A clean surface ensures a better fit and better adhesion if using an adhesive.

- Accurate Measurement: Use a tape measure to get the precise dimensions of the tank: height, width, and depth (or diameter for a cylindrical tank). Crucially, measure the lid or top of the tank separately.

- Gather Materials: You will need Expanded Polystyrene (EPS) foam boards (look for sheets with a high density for better insulation), a utility knife, a straight edge or measuring tool, insulation adhesive (polystyrene-safe), duct tape or foil tape, and a weatherproof coating (for outdoor tanks).

Cutting and Fitting the EPS Boards

- Cut the Side Panels: Based on your measurements, carefully cut the EPS boards using the utility knife. Pro Tip: Score the board deeply with the knife, then snap it cleanly along the score line.

- Ensure a Snug Fit: The goal is to create a complete thermal envelope with as few gaps as possible. Fit the cut pieces flush against the tank’s sides. For a cylindrical tank, you will need to cut smaller, curved sections that fit together or use thicker boards that naturally curve slightly with the tank.

- Account for Obstructions: Carefully measure and cut out holes for any protruding pipes, valves, or temperature/pressure relief devices. Use the smallest possible cutout to minimize thermal bridges.

- Insulate the Lid/Top: Cut a separate piece of Thermocol to fit perfectly over the tank’s lid. The top is a major source of heat loss or gain and must be covered. For outdoor tanks, ensure the lid panel is protected from water ingress.

Sealing and Protection

- Secure the Boards: Use a polystyrene-safe adhesive to secure the EPS boards to the tank surface. For an easier, less permanent solution, a secure wrap of strong, broad duct tape can hold the sheets in place.

- Seal All Seams and Gaps: This is the most critical step for optimal performance. Use the strong foil or duct tape to thoroughly seal every seam where two foam boards meet. Pay extra attention to the corners and the cutouts around pipes. Sealing gaps prevents air movement and dramatically boosts the insulation’s thermal performance.

- Weatherproof Coating (for Outdoor Tanks): If your tank is outside (e.g., a rooftop tank), the EPS must be protected from UV rays and weather. Apply a protective outer layer, such as a waterproof coating, a reflective aluminum foil cladding, or a durable exterior paint designed for insulation. UV exposure degrades polystyrene over time.

Thermocol vs. Other Water Tank Insulation Materials

While Thermocol (EPS) is a fantastic, budget-friendly option, homeowners often consider other materials. Comparing the pros and cons helps make an informed decision based on climate and budget.

| Insulation Material | Key Advantages | Typical R-Value (per inch) | Best For | Considerations |

| Thermocol (EPS) | Low cost, lightweight, moisture resistant, DIY-friendly. | $3.6 – 4.2$ | Residential, cold water storage, budget projects. | Must be protected from UV light and fire. |

| Fiberglass Jacket/Blanket | Very easy DIY installation, widely available, flexible. | $3.0 – 3.7$ | Standard hot water cylinders, indoor use. | Becomes less effective if it gets wet or compressed, often needs a protective wrap. |

| Polyurethane (PUF) Spray Foam | Seamless application (no gaps), high R-value, adheres perfectly to irregular shapes. | $5.5 – 6.5$ | Commercial/industrial tanks, irregular shapes, premium performance. | Requires professional installation; higher initial cost. |

| Extruded Polystyrene (XPS) | Higher compressive strength than EPS, better moisture resistance. | $5.0$ | Underground tanks, high-moisture areas. | More expensive than EPS, less environmentally friendly due to blowing agents. |

Thermocol strikes the best balance between cost-effectiveness and thermal efficiency for the average residential or small commercial water storage solution.

The Long-Term Return on Investment (ROI)

The initial cost of materials for insulating your water tank with EPS is quickly recouped through tangible savings.

Reduced Energy Consumption

For hot water cylinders, insulation drastically reduces heat loss, meaning the element or boiler doesn’t have to work as hard or as often. This directly translates to lower utility bills. Studies show that insulating an uninsulated or poorly insulated tank can save a significant percentage of the energy used for water heating. The thermal envelope created by the EPS maintains the stored heat, offering reliable hot water when you need it.

Extended Water Heater Lifespan

When a heater cycles on less frequently due to reduced heat loss, there is less wear and tear on its components. A well-insulated tank reduces the stress on the heating element and the tank itself, contributing to a longer, more reliable service life for your entire water heating system.

Climate Comfort and Safety

- Preventing Water Freezing: For tanks in cold areas like lofts, the insulation provides a crucial barrier against freezing temperatures, preventing costly plumbing repairs caused by frozen and burst pipes.

- Comfort in Summer: For rooftop tanks, the reflective coating applied over the Thermocol sheets in combination with the insulation layer minimizes heat gain from the sun, keeping the water refreshingly cooler. This is an essential consideration for homeowners in hot climatic regions.

Best Practices and Pro Tips for Maximum Performance

To ensure your Thermocol insulation for water tanks delivers its absolute best, follow these crucial tips:

Routine Inspection: Periodically check the tank for signs of moisture, damage to the protective layer, or gaps that have opened up due to settling. Maintaining the seal is key to sustained energy efficiency.

Choose the Right Thickness: Always opt for the thickest EPS board your space and budget allow. Thickness directly correlates with the R-value and overall thermal performance. Never compress the insulation, as this reduces its effectiveness.

Prioritize the Top and Bottom: Heat rises, so ensuring the lid is heavily and seamlessly insulated is paramount to reducing heat loss. The bottom of the tank (if accessible and not sitting directly on a heated floor) also needs attention to prevent heat escaping into the floor or ground.

Address Thermal Bridges: A thermal bridge is any area where the insulation layer is interrupted, allowing heat to flow freely. Pipes, mounting brackets, and access panels are common culprits. Use foam tape or sealant to fill every tiny gap around pipes after cutting the holes for the EPS board. This detail separates a good job from an excellent one.

Protect from the Elements: For outdoor tanks, UV protection is mandatory. A weatherproof coating or metal cladding shields the EPS from degradation, ensurinhttps://thermocolsheet.com/eps-foam/g its long-lasting insulation performance.

Conclusion: Securing Your Water Future with Thermocol

Thermocol insulation for water tanks is a proven, economical, and highly effective method for controlling water temperature, dramatically reducing utility bills, and protecting your property from the risks of extreme heat or cold. By choosing Expanded Polystyrene (EPS) foam boards, you invest in a solution that offers excellent thermal resistance, is simple to install, and provides long-term energy savings.

From the initial DIY water tank insulation project to enjoying decades of consistent water temperature and lower heating costs, the choice to insulate your water storage tank with Thermocol is a wise step towards a more sustainable and comfortable home or business. Embrace this smart material and turn your tank into an energy-saving asset.

FAQ’S

For most residential hot water tanks (cylinders), Google SEO guidelines often recommend aiming for a minimum R-value of R-12 to R-24 for the insulation jacket, especially in colder climates. Since Thermocol (EPS) typically has an R-value of around $4.0$ per inch, you should use an insulation sheet that is at least 3 inches thick to meet the R-12 minimum. For better energy efficiency and long-term heat loss prevention, especially in unheated spaces like lofts, aim for 4 to 6 inches of high-density EPS.

Yes, Thermocol insulation for water tanks installed outdoors, such as on a rooftop, absolutely requires protection. Expanded Polystyrene (EPS) is susceptible to degradation from UV rays (sunlight) and moisture ingress. To maintain its thermal performance and structural integrity, you must apply a weatherproof coating—preferably a thick, reflective exterior paint or a layer of aluminum foil cladding—over the EPS foam boards. This shields the material, prevents thermal bridging through gaps, and helps minimize solar radiation heat gain.

The payback period for DIY water tank insulation using affordable Thermocol sheets is usually very short, often between 6 to 18 months, depending on your existing insulation level and energy tariffs. Insulating a poorly covered hot water heater tank can reduce heat loss by up to $25\%-45\%$. The material’s low initial cost and its immediate impact on reducing the frequency of the water heater cycling on ensures a quick return on investment (ROI), leading to years of pure energy savings afterward.