Thermal insulation plays a vital role in modern construction by improving indoor comfort, reducing energy consumption, and protecting structures from extreme temperatures in Pakistan. Whether it is used in homes, offices, factories, or warehouses, the right insulation system can significantly enhance building performance and long-term cost efficiency.

This guide explains thermal insulation in detail, its applications, materials, and why it is essential for residential, commercial, and industrial environments.

Importance of Thermal Insulation in Modern Construction

Thermal insulation is no longer optional in modern construction. It is a key component of energy-efficient design and sustainable building practices.

Key Benefits:

- Improved indoor temperature control

- Lower electricity and fuel consumption

- Reduced operational costs

- Enhanced building durability

- Better acoustic performance

Thermal insulation also helps buildings comply with modern energy efficiency standards and environmental regulations.

Thermal Insulation For Houses

It improves comfort by maintaining consistent indoor temperatures throughout the year. Insulated homes experience less heat penetration in summer and reduced heat loss in winter.

Common residential insulation areas include:

- Roofs and ceilings

- External and internal walls

- Floors and basements

Using the correct insulation material in houses helps homeowners reduce energy bills while improving living conditions.

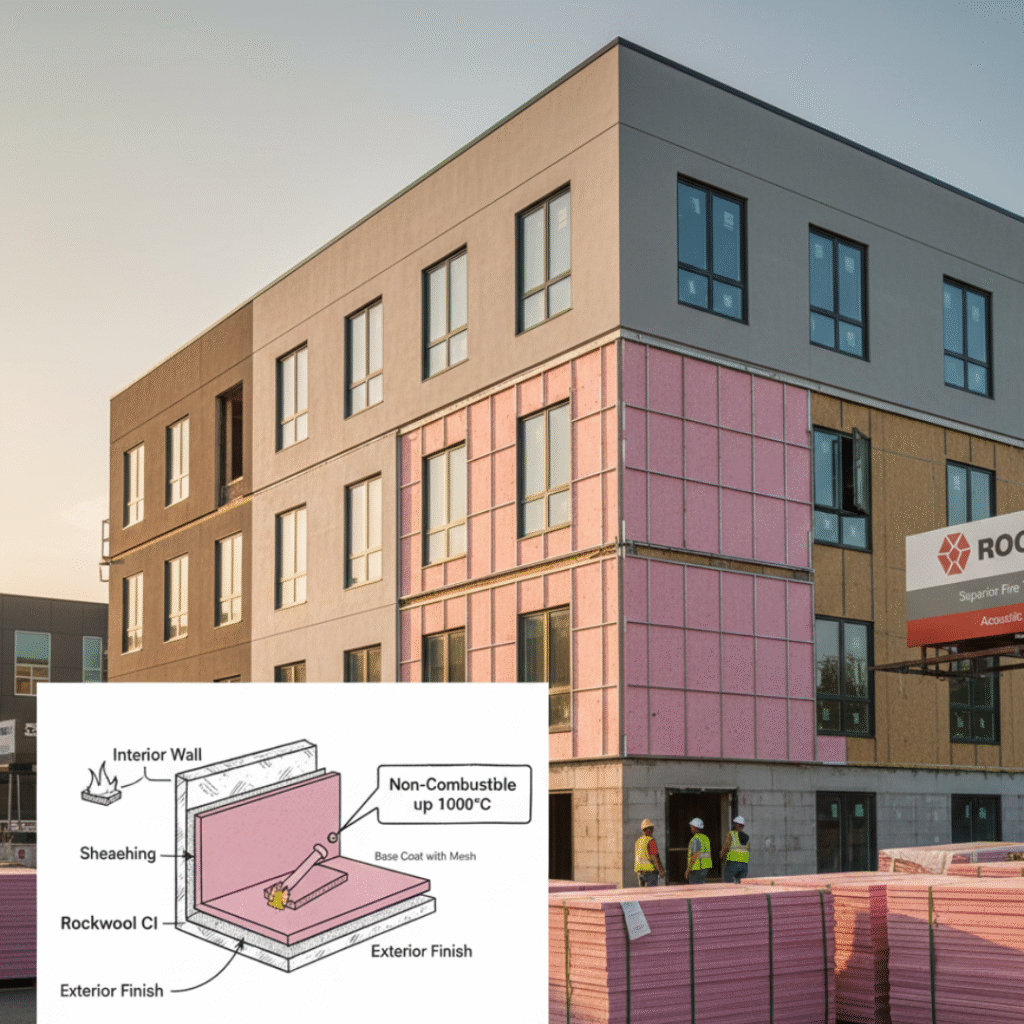

Thermal Insulation For Buildings in Pakistan

Thermal insulation in buildings is widely used in residential apartments, commercial plazas, and mixed-use developments. Large structures require insulation systems that perform consistently across wide surface areas.

Insulation in buildings helps:

- Maintain uniform temperature across floors

- Protect structural elements from thermal stress

- Reduce HVAC system load

Thermal insulation sheets and foam-based solutions are commonly applied in walls, roofs, and façades of multi-story buildings.

Thermal Insulation For Offices

It contributes directly to employee comfort and productivity. Stable indoor temperatures reduce fatigue and improve work efficiency.

Office insulation solutions are designed to:

- Minimize heat gain through glass and walls

- Reduce noise from external environments

- Maintain consistent cooling across workspaces

Well-insulated offices also experience lower long-term maintenance and energy costs.

Thermal Insulation For Factories

Thermal insulation in factories is essential for controlling heat generated by machinery and industrial processes. Insulation helps maintain safe working conditions and protects sensitive equipment.

Factory insulation is commonly used for:

- Roofs and metal sheds

- Machinery enclosures

- Production halls

Industrial-grade insulation materials are selected based on temperature resistance, durability, and fire safety.

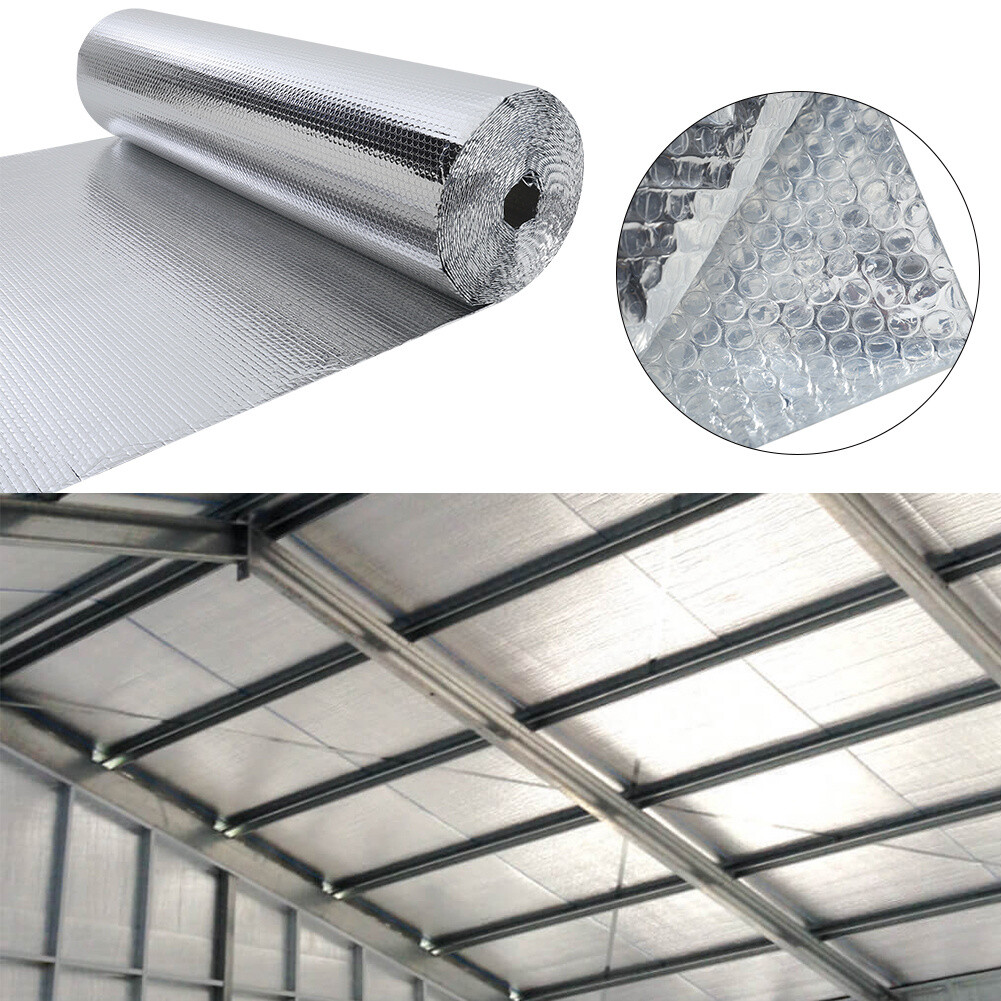

Thermal Insulation For Warehouses

Thermal insulation in warehouses is critical for temperature control, especially where goods are stored for long durations. Insulation protects products from heat damage and moisture-related issues.

Warehouses benefit from insulation by:

- Reducing temperature fluctuations

- Improving storage safety

- Lowering cooling and ventilation costs

Thermal insulation foam and sheets are widely used for warehouse roofs and walls due to their lightweight and efficient performance.

Thermal Insulation Foam Explained

It is a popular solution due to its high insulation efficiency and ease of installation. Foam insulation expands to fill gaps, reducing air leakage and thermal bridging.

Common foam applications include:

- Roof insulation

- Wall cavity filling

- Cold storage facilities

Foam-based insulation provides excellent thermal resistance while keeping overall structure weight low.

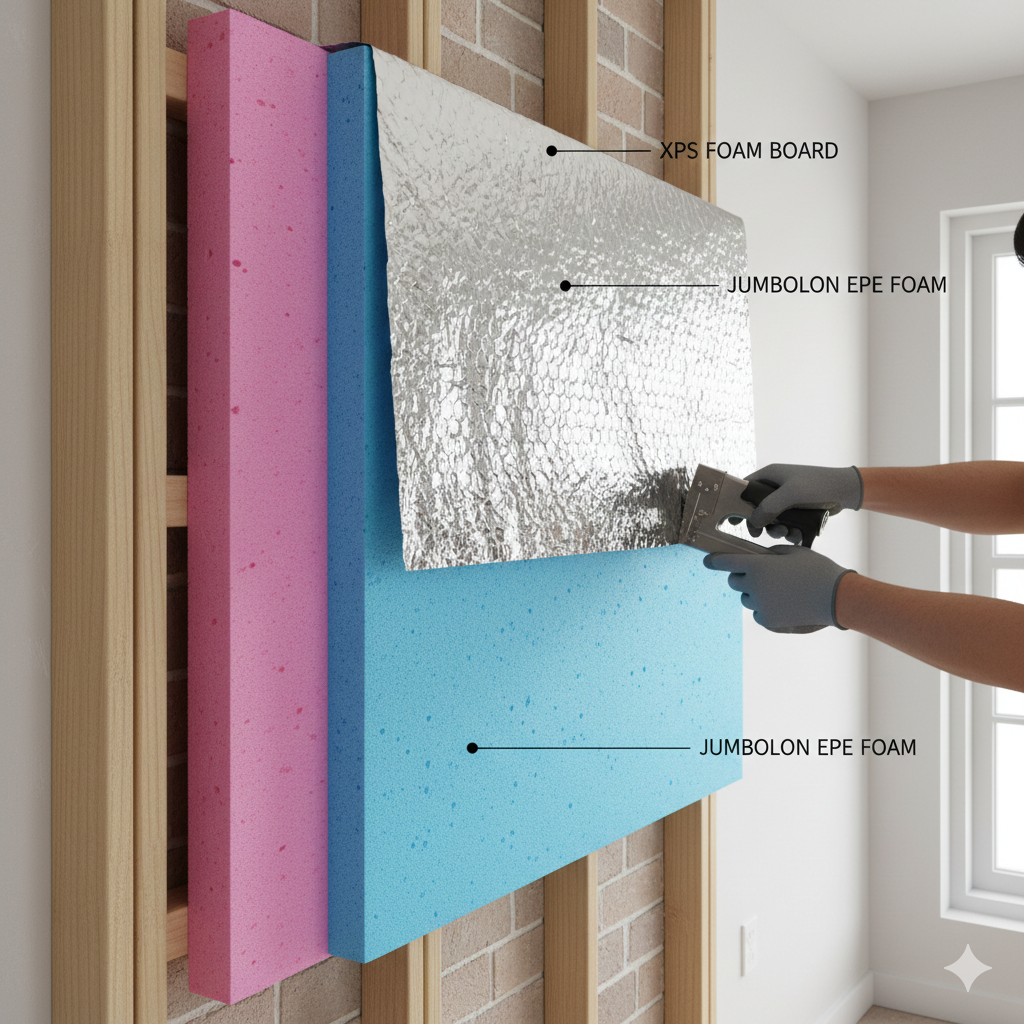

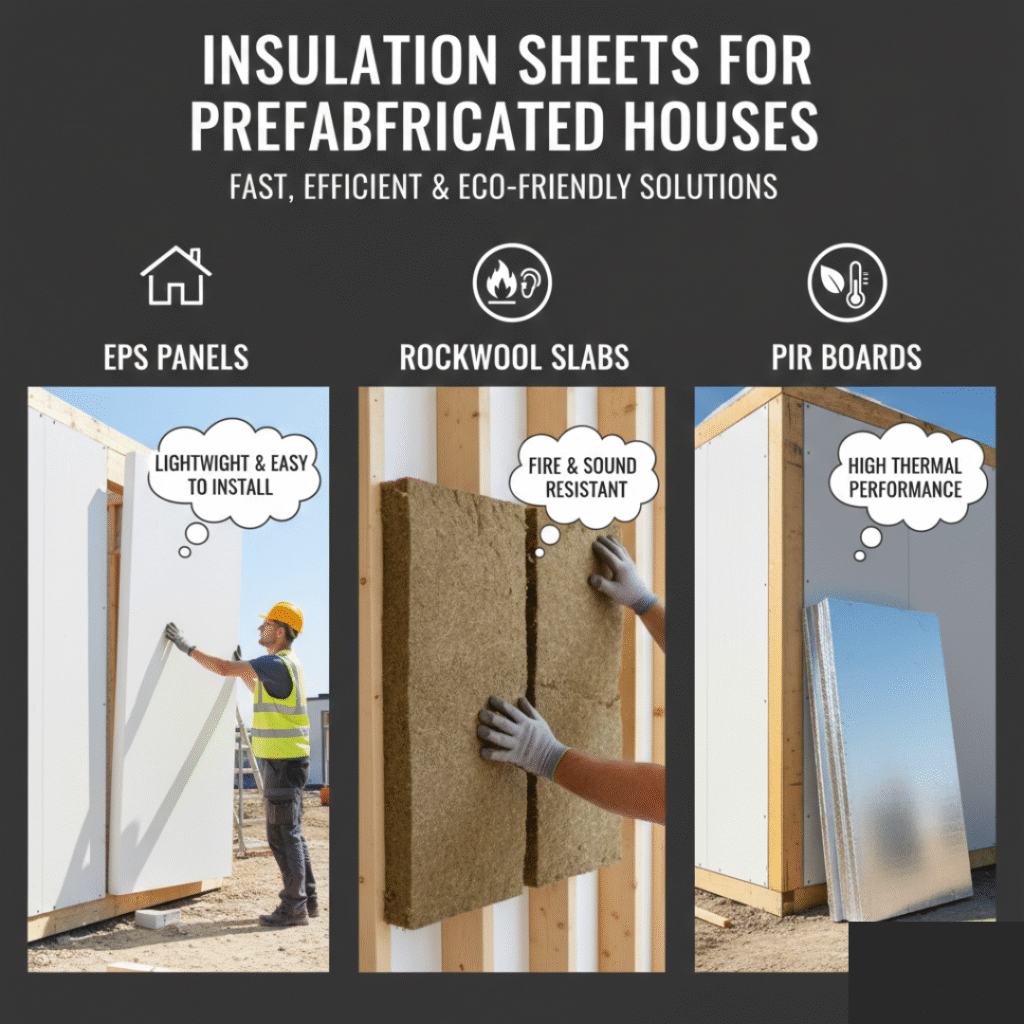

Thermal Insulation Materials List

Choosing the right material is crucial for effective insulation. Below is a commonly used thermal insulation materials list in construction:

- Expanded Polystyrene (EPS)

- Extruded Polystyrene (XPS)

- Polyurethane Foam (PU)

- Glass Wool

- Rock Wool

- Reflective insulation sheets

Each material varies in thermal resistance, density, cost, and suitability depending on the project type.

How to Choose the Right Thermal Insulation Solution

Selecting the correct insulation depends on:

- Building type (residential, commercial, industrial)

- Climate conditions

- Budget constraints

- Installation location

A professional assessment ensures optimal insulation performance and long-term savings.

Long-Term Value of Thermal Insulation

Investing in thermal insulation is a long-term decision that delivers continuous returns through reduced energy costs and enhanced property value. Proper insulation also supports environmentally responsible construction practices by lowering carbon emissions.

Conclusion

Thermal insulation is a critical element in modern construction, offering comfort, efficiency, and protection across homes, buildings, offices, factories, and warehouses in Pakistan. With various insulation sheets, foam systems, and material options available, selecting the right solution ensures better performance and lasting benefits.

A well-planned insulation system is not just a construction feature—it is a smart investment for the future.

FAQ’S

Thermal insulation is used to reduce heat transfer between indoor and outdoor environments. It helps maintain comfortable indoor temperatures, reduces electricity consumption, and protects buildings from extreme weather conditions.

Roofs, external walls, ceilings, and industrial sheds benefit the most from thermal insulation. Proper insulation in these areas improves energy efficiency in houses, offices, factories, and warehouses.

Common thermal insulation materials include EPS and XPS sheets, polyurethane foam, glass wool, rock wool, and reflective insulation sheets. The right choice depends on building type, budget, and insulation requirements.

Yes, thermal insulation is highly suitable for factories, offices, warehouses, and commercial buildings. It helps control indoor temperatures, protects equipment, and lowers long-term operational costs.