Rising temperatures, increasing electricity bills, and growing awareness of energy efficiency have made wall insulation sheets an essential part of modern construction in Pakistan. Whether for new buildings or renovation projects, wall insulation plays a key role in maintaining indoor comfort and reducing heat transfer.

This guide explains everything you need to know about wall insulation sheet Pakistan, including pricing, material options, types of wall insulation, and how to choose the best solution for your needs.

What Is a Wall Insulation Sheet?

A wall insulation sheet is a thermal barrier installed inside or on external walls to reduce heat movement between outdoor and indoor environments. In Pakistan’s hot climate, walls absorb significant heat during the day, which then transfers indoors.

Proper wall insulation slows this heat flow and helps keep interiors cooler without relying heavily on air conditioning.

Importance of Wall Insulation in Pakistan

Wall insulation is becoming increasingly popular as part of thermal insulation in Pakistan due to several benefits:

- Reduced indoor heat gain

- Improved thermal comfort

- Lower electricity consumption

- Protection of interior finishes

- Better building energy performance

Unlike roof insulation, wall insulation works continuously throughout the day, especially on sun-exposed sides of buildings.

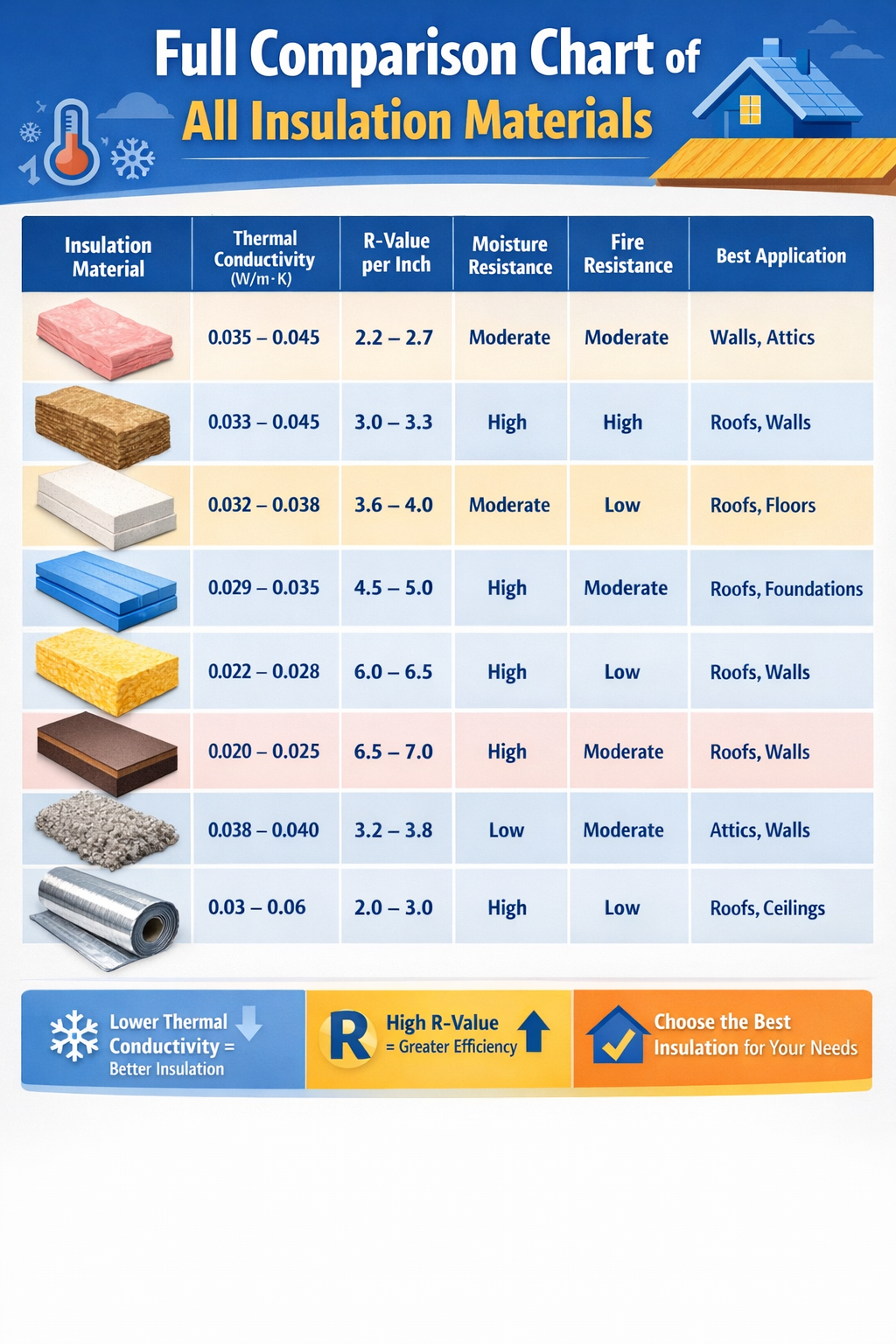

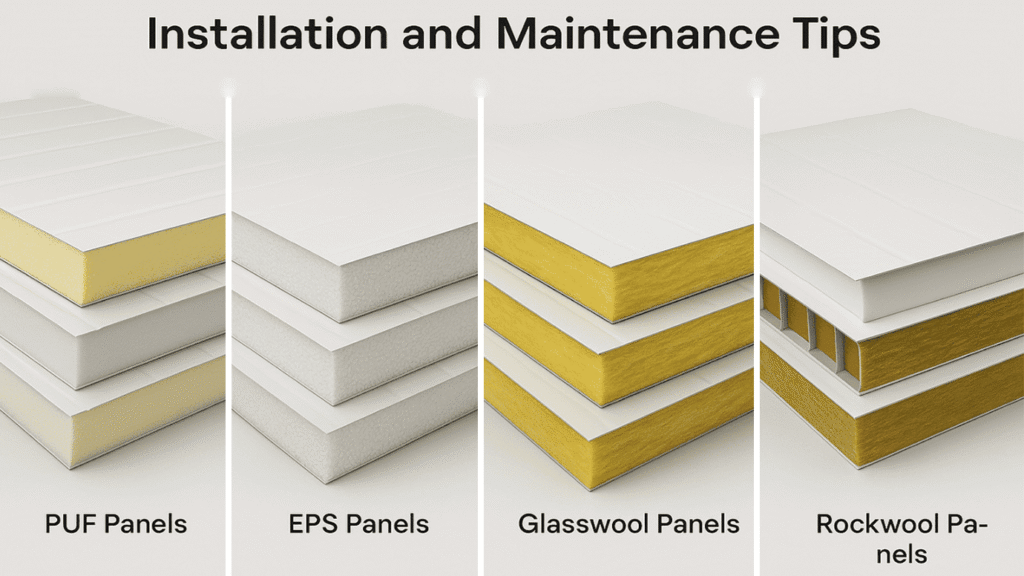

Types of Wall Insulation in Pakistan

Understanding the types of wall insulation in Pakistan helps in selecting the right solution based on budget, building type, and performance needs.

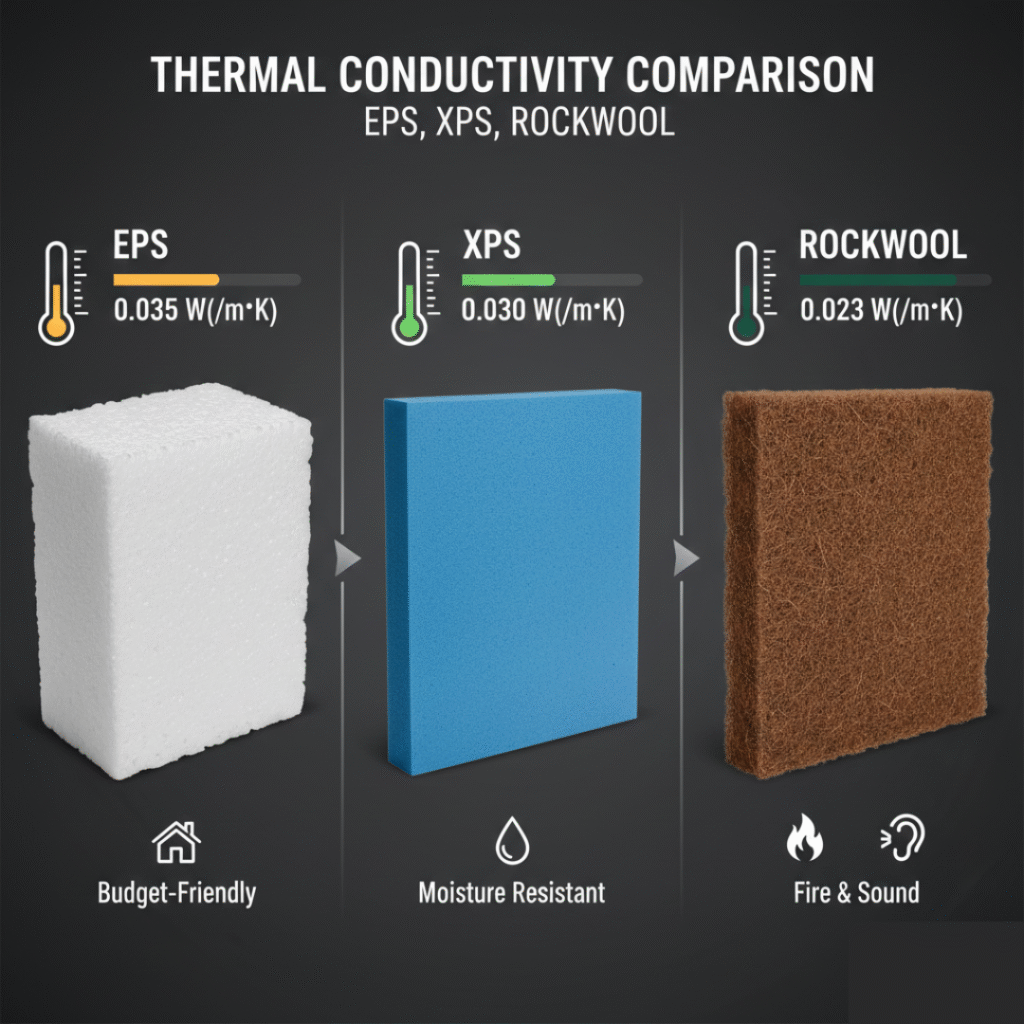

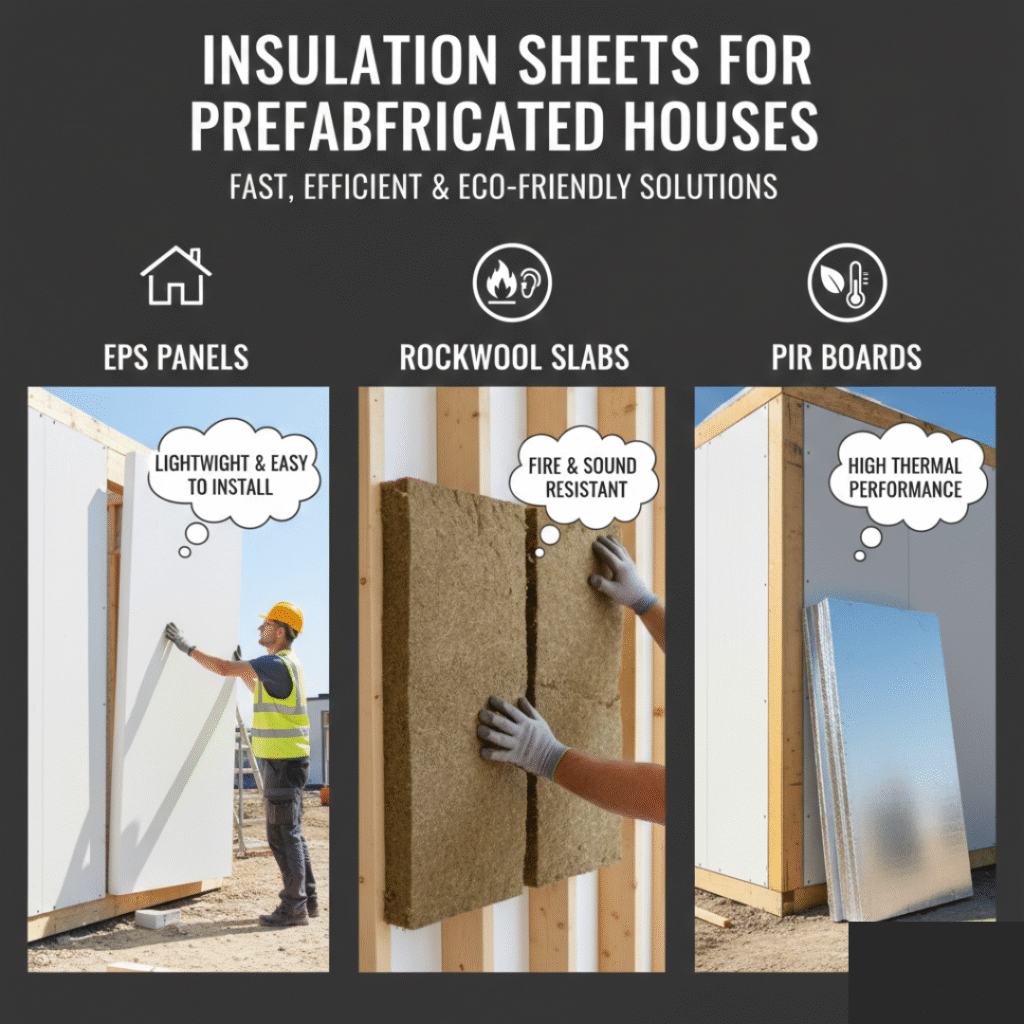

1. EPS (Thermocol) Wall Insulation Sheets

EPS sheets are widely used due to affordability and availability. They are lightweight and easy to install, making them a popular choice for residential projects.

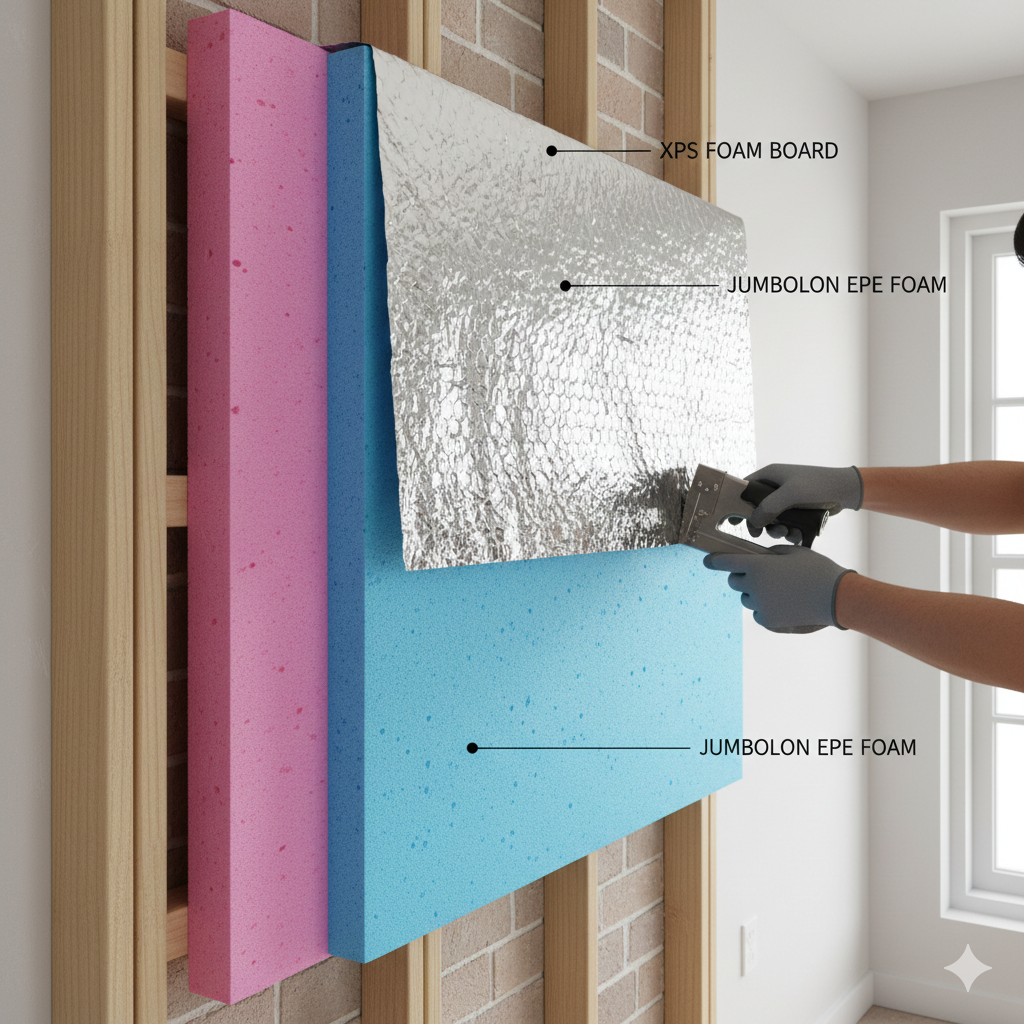

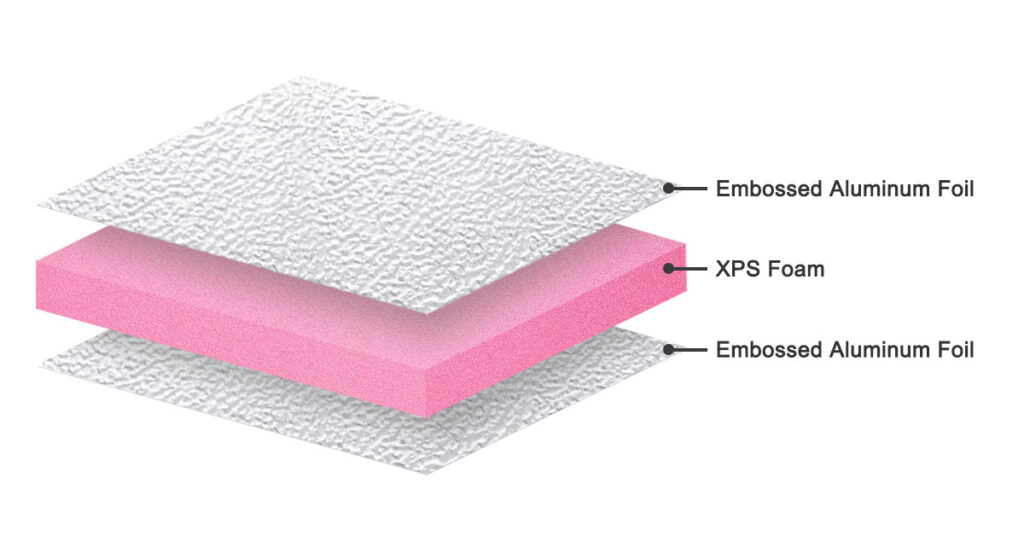

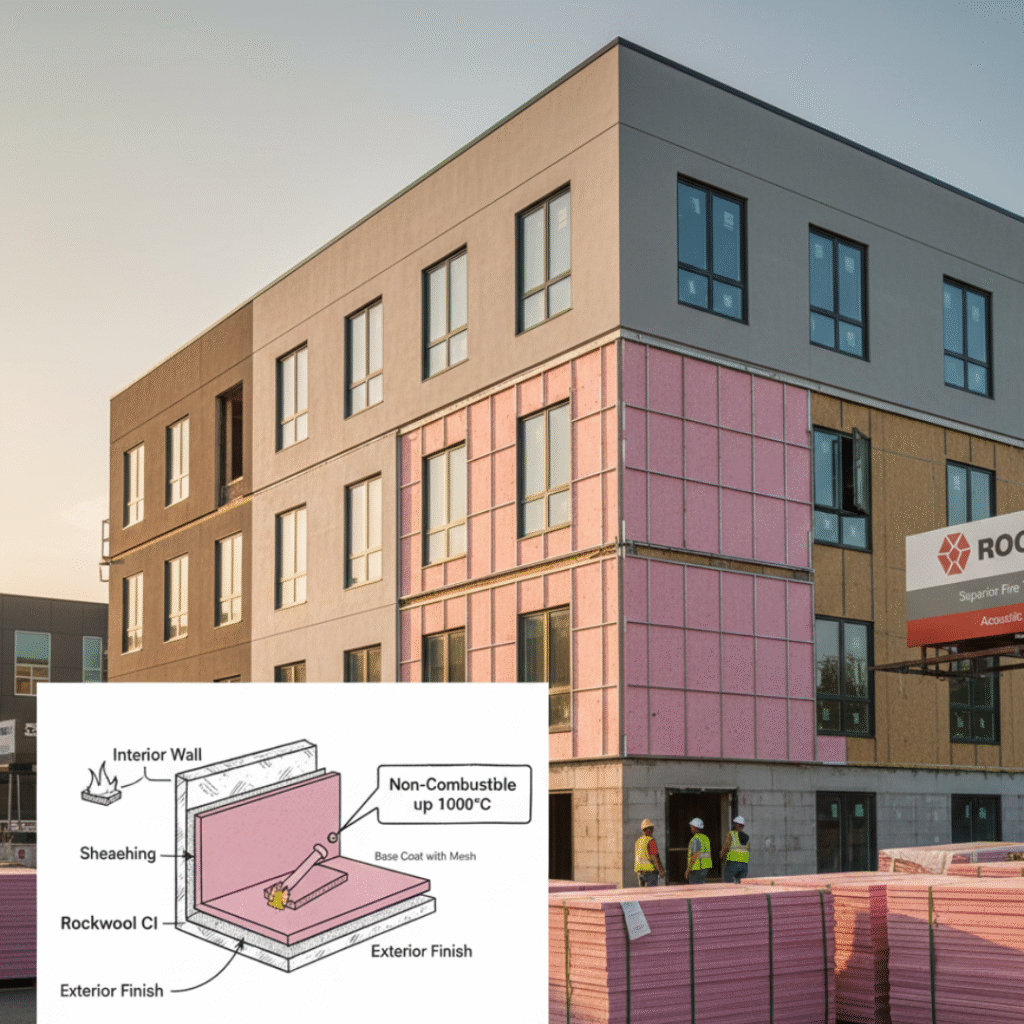

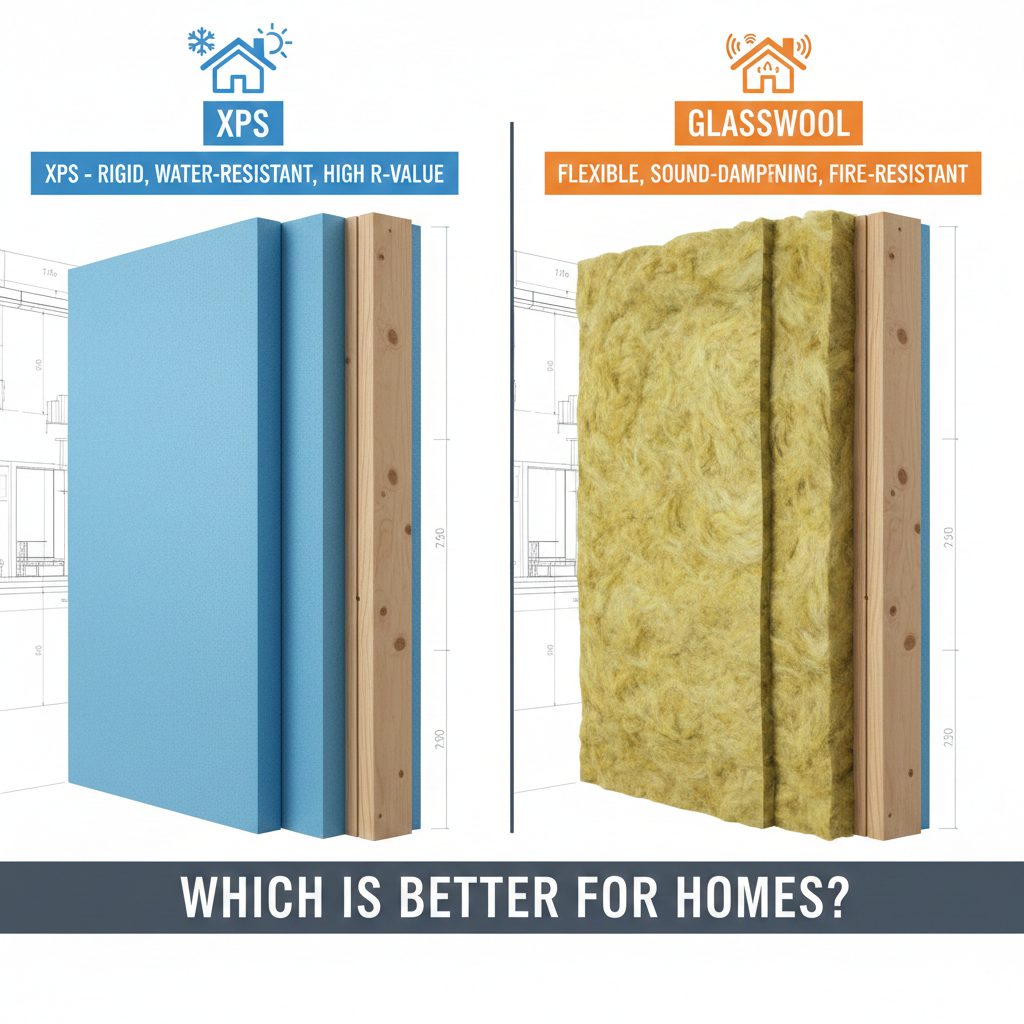

2. XPS Insulation Sheets

XPS sheets offer higher density and better moisture resistance compared to EPS. They are commonly used in commercial and industrial buildings where durability is required.

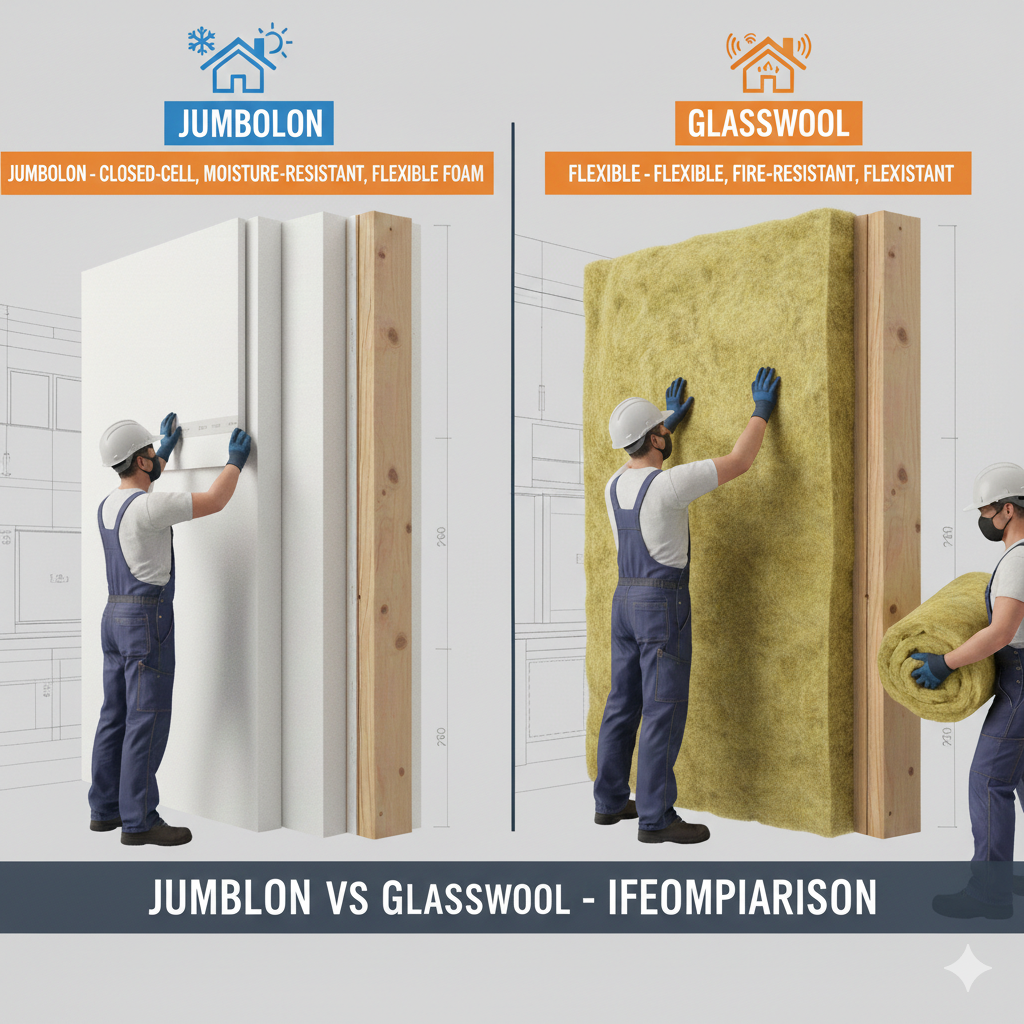

3. Foam-Based Wall Insulation

Foam insulation sheets provide strong thermal resistance and seamless coverage. They are ideal for buildings that require higher insulation performance.

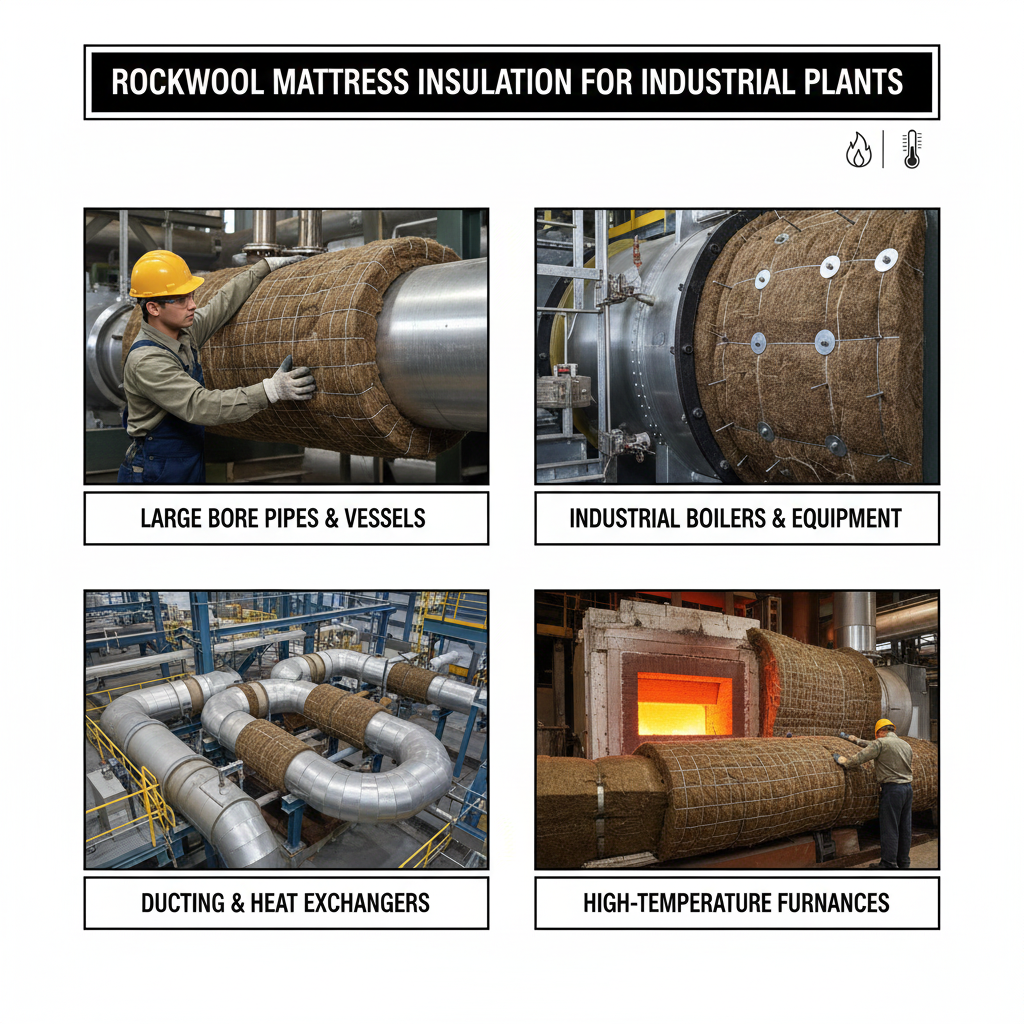

4. Fibrous Insulation Materials

Glass wool and similar fibrous materials are sometimes used inside wall cavities to improve insulation and sound absorption.

Wall Insulation Sheet Pakistan Price – What Affects Cost?

The wall insulation sheet Pakistan price varies depending on several factors:

- Material type (EPS, XPS, foam, fibrous)

- Sheet thickness

- Installation method

- Project size

- City-wise labor costs

Buyers often compare overall costs using thermal insulation sheet price in Pakistan, which includes both material and installation expenses.

Cheap Wall Insulation in Pakistan – Is It Worth It?

Many property owners look for cheap wall insulation in Pakistan to reduce initial costs. Budget-friendly options like EPS sheets can offer acceptable performance when installed correctly.

However, cheaper insulation may have:

- Lower durability

- Reduced thermal resistance

- Shorter lifespan

Choosing the lowest price should always be balanced with long-term energy savings and performance expectations.

Best Wall Insulation in Pakistan – How to Choose

The best wall insulation in Pakistan is not a single product but the one that suits your specific needs. When selecting insulation, consider:

- Building orientation

- Exposure to direct sunlight

- Climate conditions

- Budget and long-term cost savings

Homes often benefit from EPS or foam insulation, while offices and commercial buildings may require higher-density solutions.

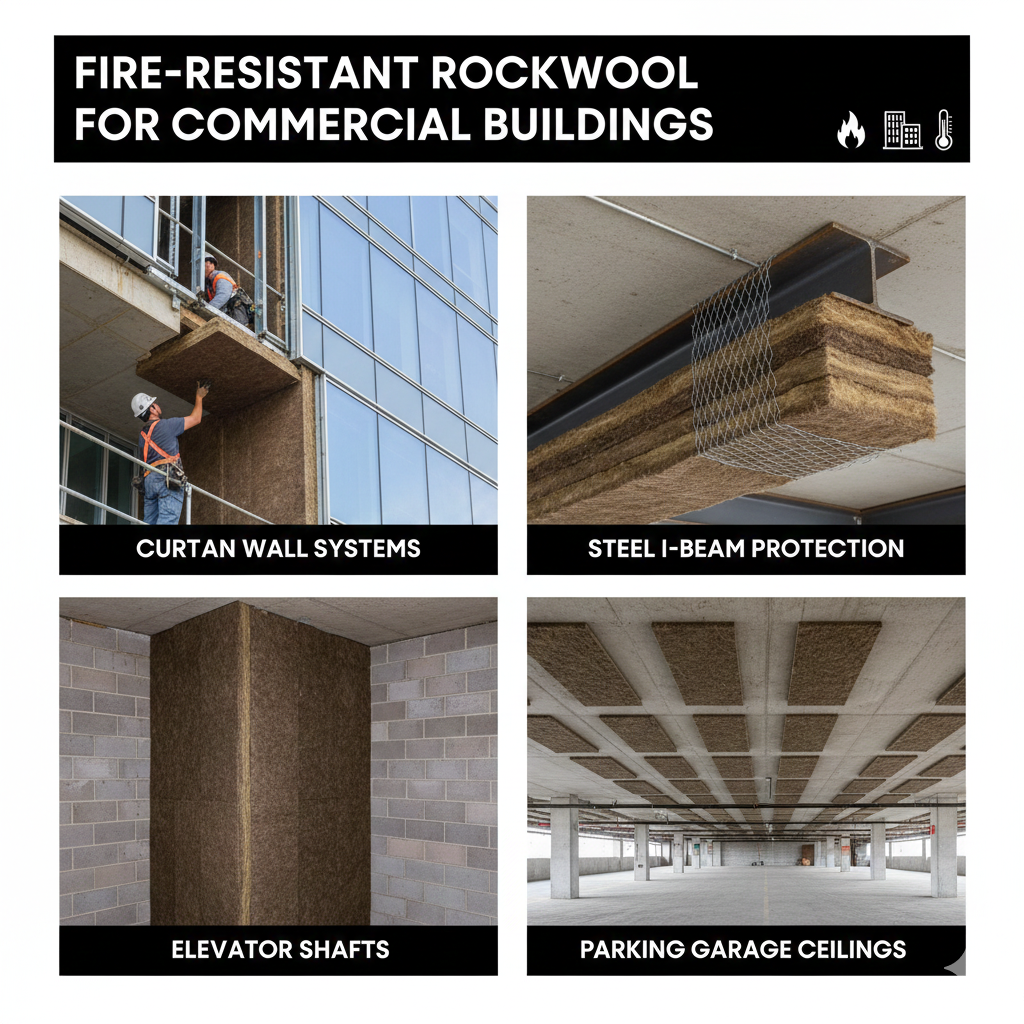

Applications of Wall Insulation Sheets

Wall insulation sheets are commonly used in:

- Residential houses

- Apartments and flats

- Office buildings

- Educational institutions

- Hospitals and commercial facilities

Their flexibility makes them suitable for both internal and external wall applications.

Installation Considerations

Proper installation is critical for insulation performance. Gaps, poor sealing, or incorrect thickness can reduce effectiveness. Professional installation ensures that insulation works as intended and delivers long-term benefits.

Long-Term Benefits of Wall Insulation

Installing wall insulation sheets offers long-term advantages such as:

- Lower cooling costs

- Improved indoor comfort

- Reduced environmental impact

- Increased property value

Over time, insulation pays for itself through energy savings.

Final Thoughts

As energy costs rise and climate conditions become more extreme, wall insulation is no longer optional. Investing in the right wall insulation sheet Pakistan solution helps create comfortable, energy-efficient living and working spaces.

By understanding material types, pricing factors, and performance differences, you can make an informed decision that delivers lasting value.

FAQ’S

The best wall insulation sheet depends on budget and building requirements. EPS (thermocol) sheets are widely used for houses due to affordability, while XPS and foam insulation sheets are preferred for commercial and industrial buildings.

Wall insulation cost in Pakistan varies based on material type, thickness, and installation method. Prices can differ from city to city due to labor rates and material availability.

Yes, wall insulation sheets can be installed in existing buildings without major structural changes. Internal wall insulation is commonly used for renovation projects.

Yes, wall insulation significantly reduces heat transfer through external walls, helping maintain cooler indoor temperatures and reducing reliance on air conditioning.