Thermal insulation has become a practical necessity in Pakistan due to rising temperatures and increasing electricity costs. Among different thickness options, 12mm thermal insulation sheets are widely used because they offer a balance between cost, performance, and ease of installation.

This blog provides a complete overview of 12mm thermal insulation price in Pakistan, including popular materials such as thermocol and jumbolon, city-wise pricing trends, and factors that influence overall cost.

What Is 12mm Thermal Insulation?

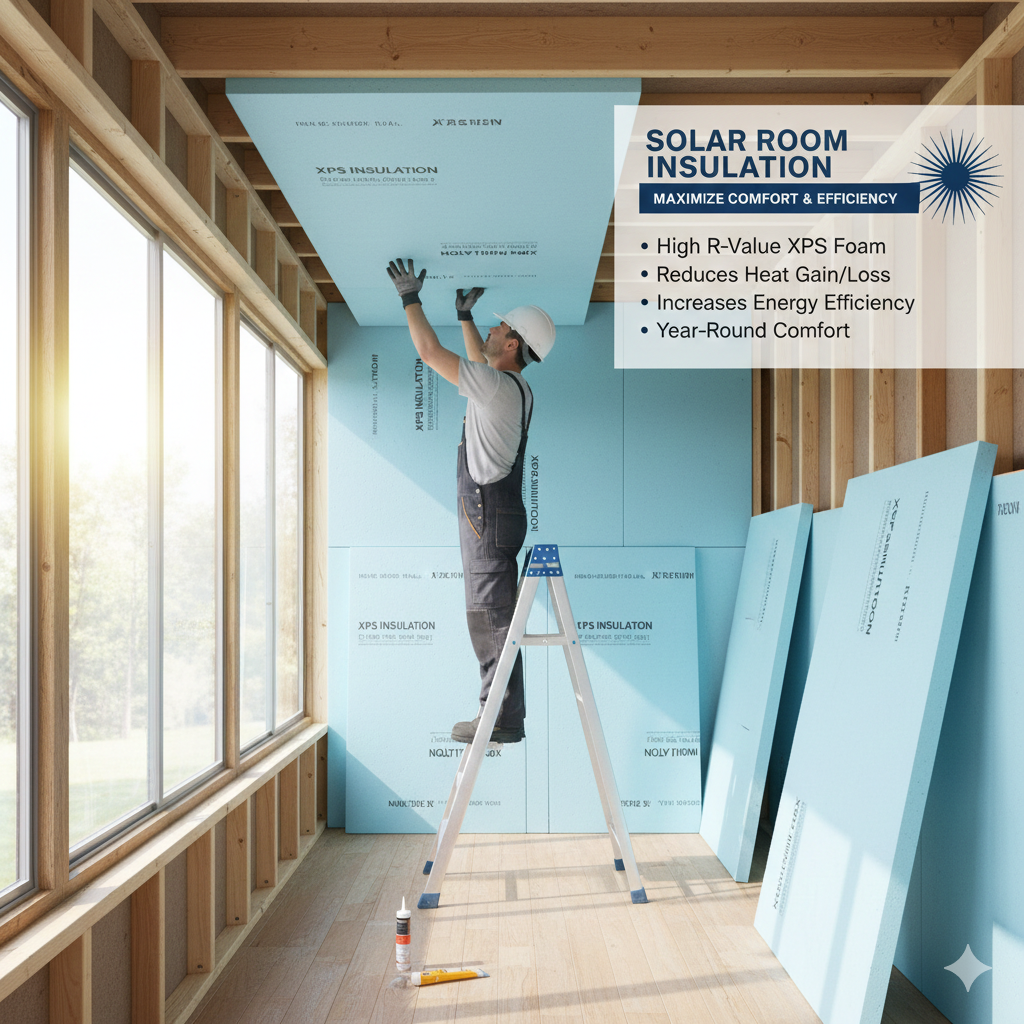

A 12mm thermal insulation sheet is a thin insulation layer designed to reduce heat transfer through roofs, walls, and ceilings. It is commonly used in residential houses, small offices, shops, and renovation projects where space and budget are limited.

Despite its slim profile, 12mm insulation can significantly improve indoor comfort when installed correctly.

Why 12mm Insulation Is Popular in Pakistan

The popularity of 12mm insulation sheets is driven by:

- Affordable pricing

- Lightweight structure

- Easy handling and installation

- Suitability for retrofit projects

- Availability across major cities

Many buyers compare options based on thermal insulation sheet price in Pakistan, and 12mm sheets often fall into an accessible budget range.

12mm Thermal Insulation Price in Pakistan – What Affects Cost?

The price of 12mm insulation sheets varies due to several factors:

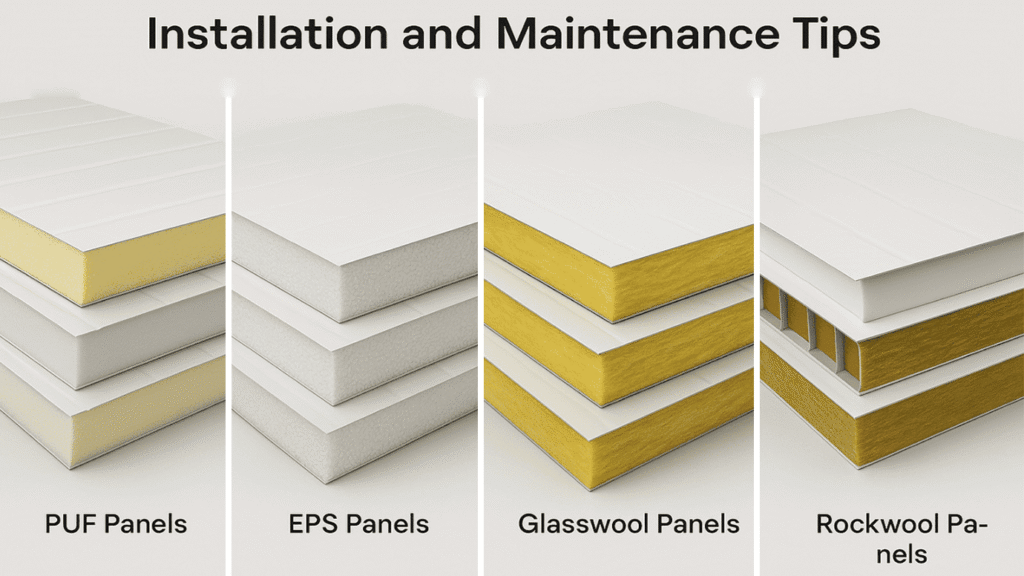

- Material type (thermocol, jumbolon, EPS-based sheets)

- Sheet density and quality

- Brand and manufacturing standards

- City-wise transportation and labor costs

- Application area (roof, wall, ceiling)

These variables explain why pricing differs across regions and suppliers.

Jumbolon Sheet Pricing for 12mm Thickness

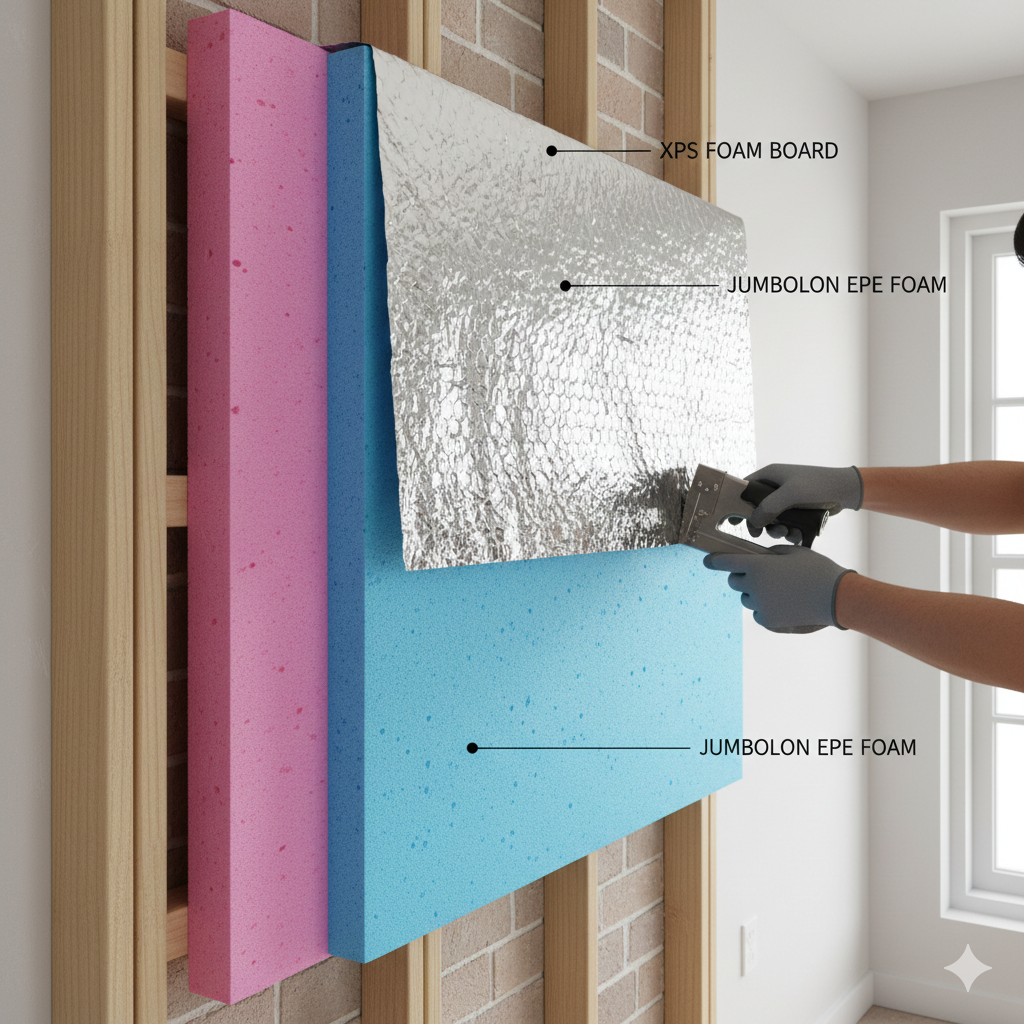

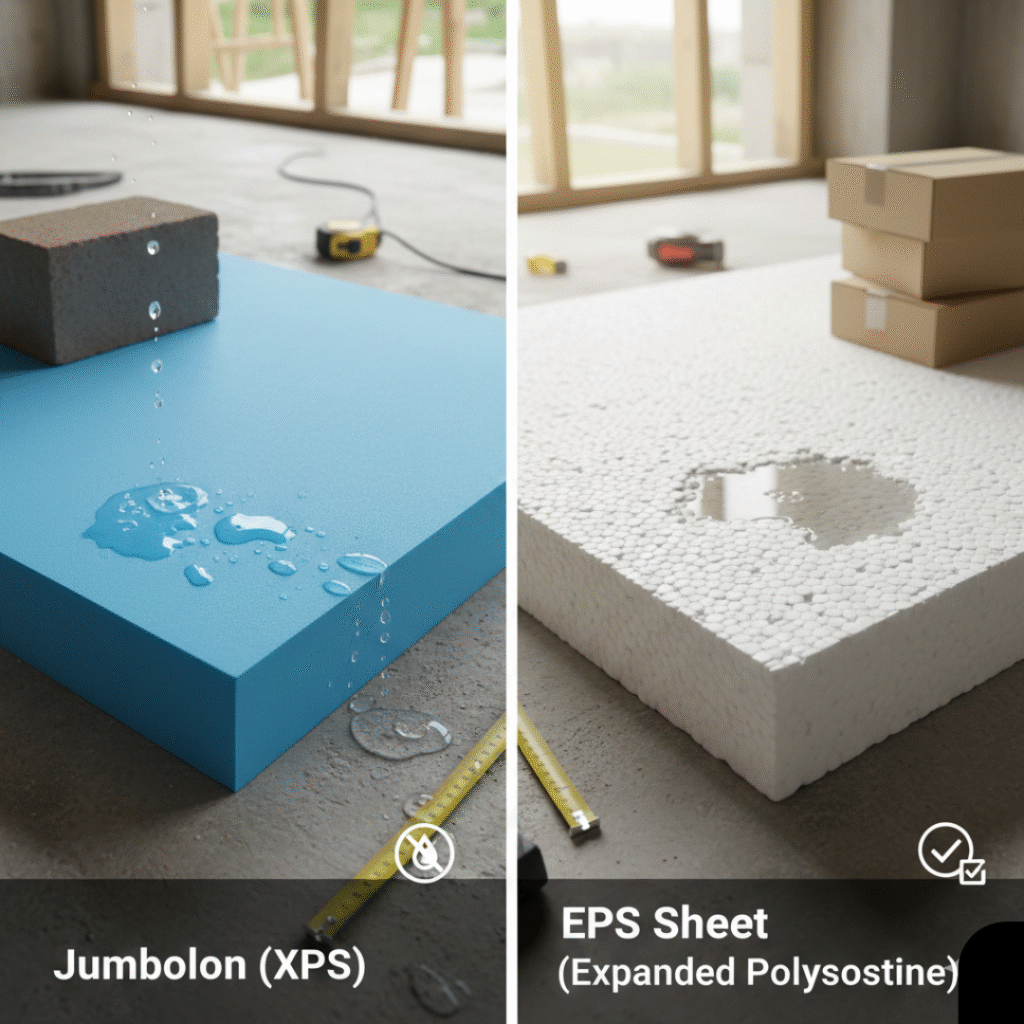

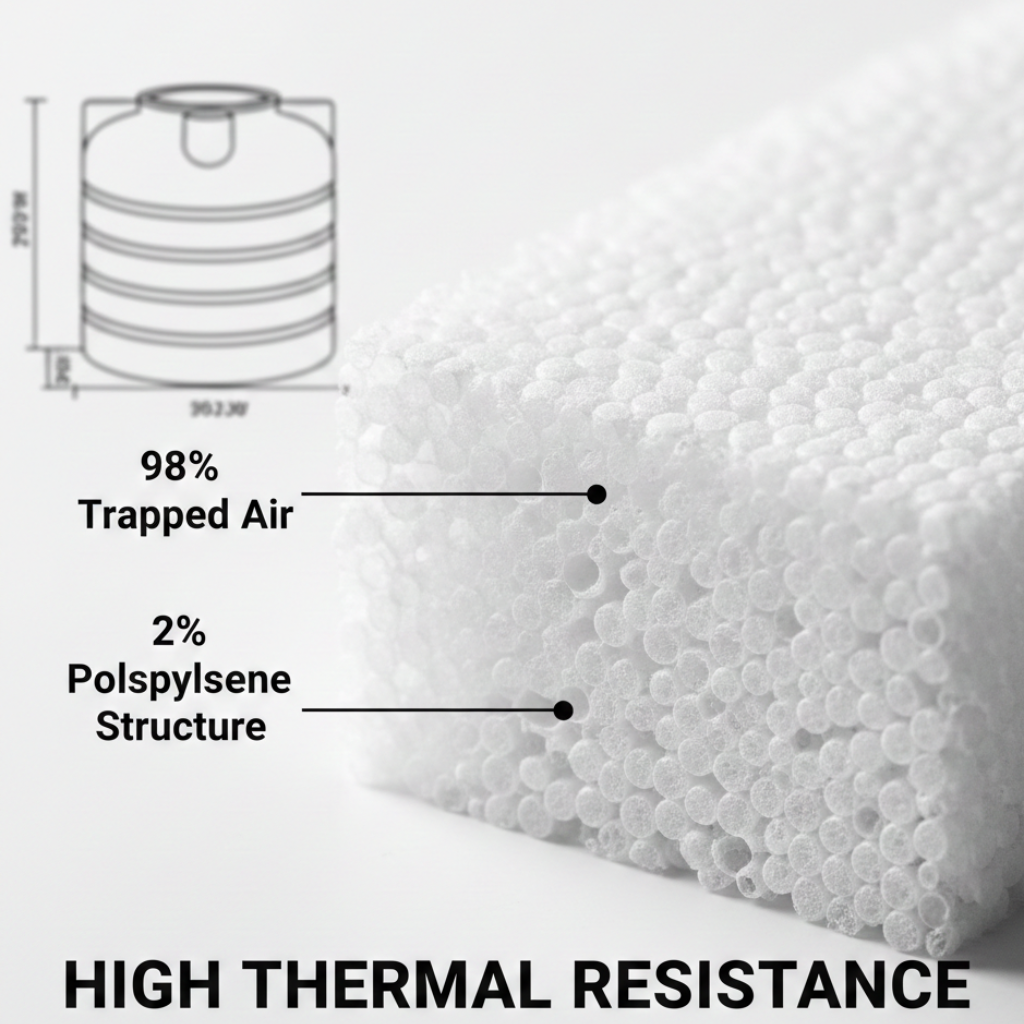

Jumbolon sheets are commonly used for thermal insulation due to their flexibility and moisture resistance. The jumbolon sheet price in Pakistan depends on thickness, roll size, and material quality.

For buyers specifically evaluating thin insulation options, the 12mm jumbolon sheet price in Pakistan is often considered a cost-effective solution for residential and light commercial applications.

Thermocol Sheet Pricing Comparison

These sheets remain one of the most widely used insulation materials in Pakistan.

- The thermocol sheet price in Lahore is generally competitive due to strong local supply and demand.

- For thicker applications, many users compare the 2 inch thermocol sheet price in Pakistan with thinner 12mm sheets to decide between higher insulation performance and lower upfront cost.

Thermocol is commonly selected when affordability and availability are key priorities.

City-Wise Price Trends for 12mm Insulation

Karachi Market Overview

The Karachi 12mm thermal insulation price in Pakistan can be slightly higher due to humidity-resistant material preferences and transportation costs. Coastal conditions often influence material selection and installation methods.

Lahore and Other Cities

Lahore typically offers stable pricing for thermocol and EPS sheets, while prices in Islamabad, Rawalpindi, and Faisalabad vary based on supplier availability and project scale.

Where 12mm Thermal Insulation Is Commonly Used

12mm insulation sheets are widely used in:

- Residential houses

- Apartment ceilings

- Office partitions

- Shops and showrooms

- Renovation and retrofit projects

They are especially useful where thicker insulation is not structurally feasible.

12mm vs Thicker Insulation Sheets

While 12mm insulation provides noticeable heat reduction, thicker sheets offer higher thermal resistance. Buyers often compare 12mm sheets with thicker options like 2-inch thermocol to evaluate performance versus cost.

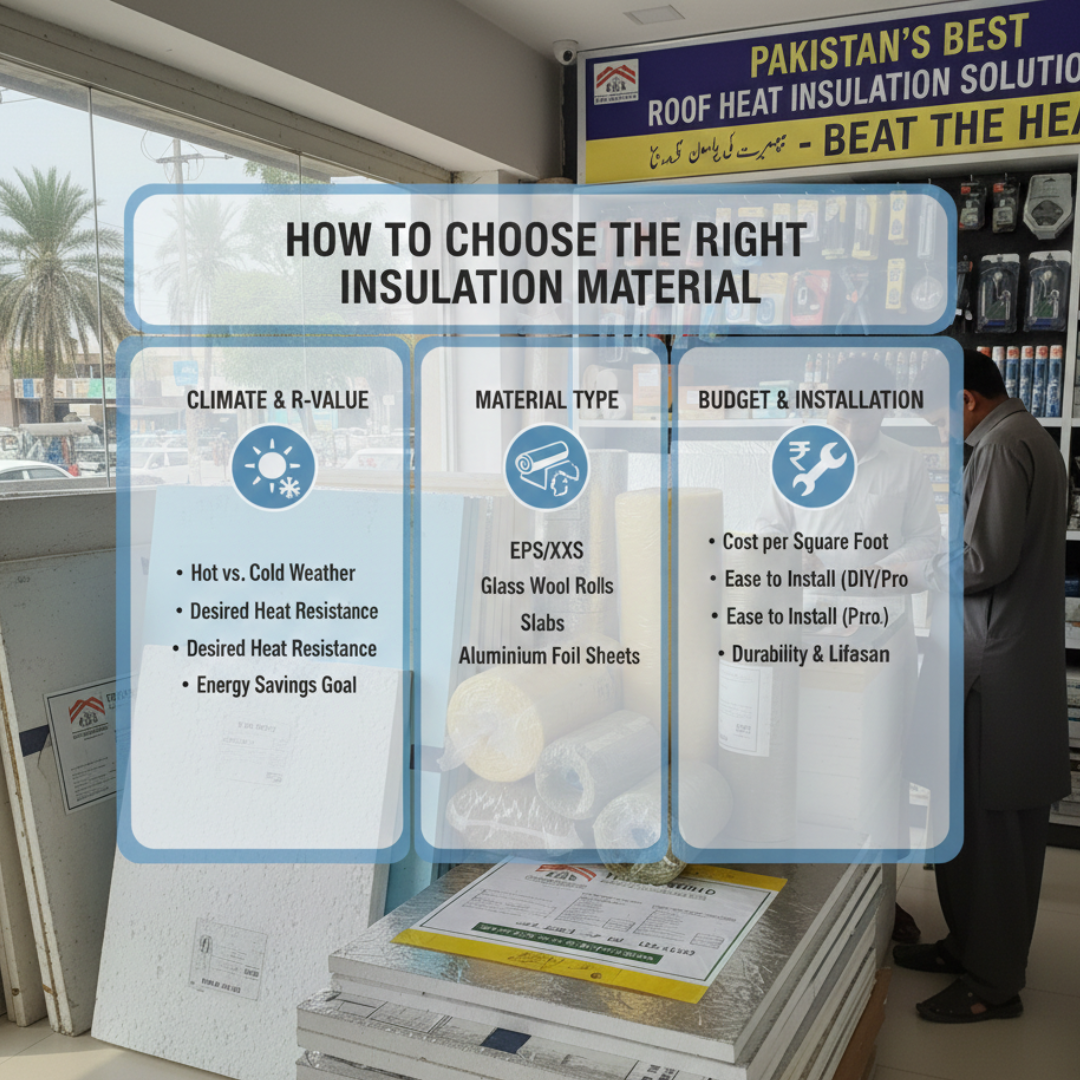

The right choice depends on:

- Heat exposure level

- Building orientation

- Budget constraints

- Long-term energy savings goals

Long-Term Value of 12mm Insulation

Although thinner insulation has a lower upfront cost, it still delivers long-term benefits such as:

- Reduced indoor heat gain

- Lower electricity consumption

- Improved indoor comfort

- Extended life of cooling systems

For many households, this makes 12mm insulation a practical entry-level solution.

How to Choose the Right 12mm Insulation Sheet

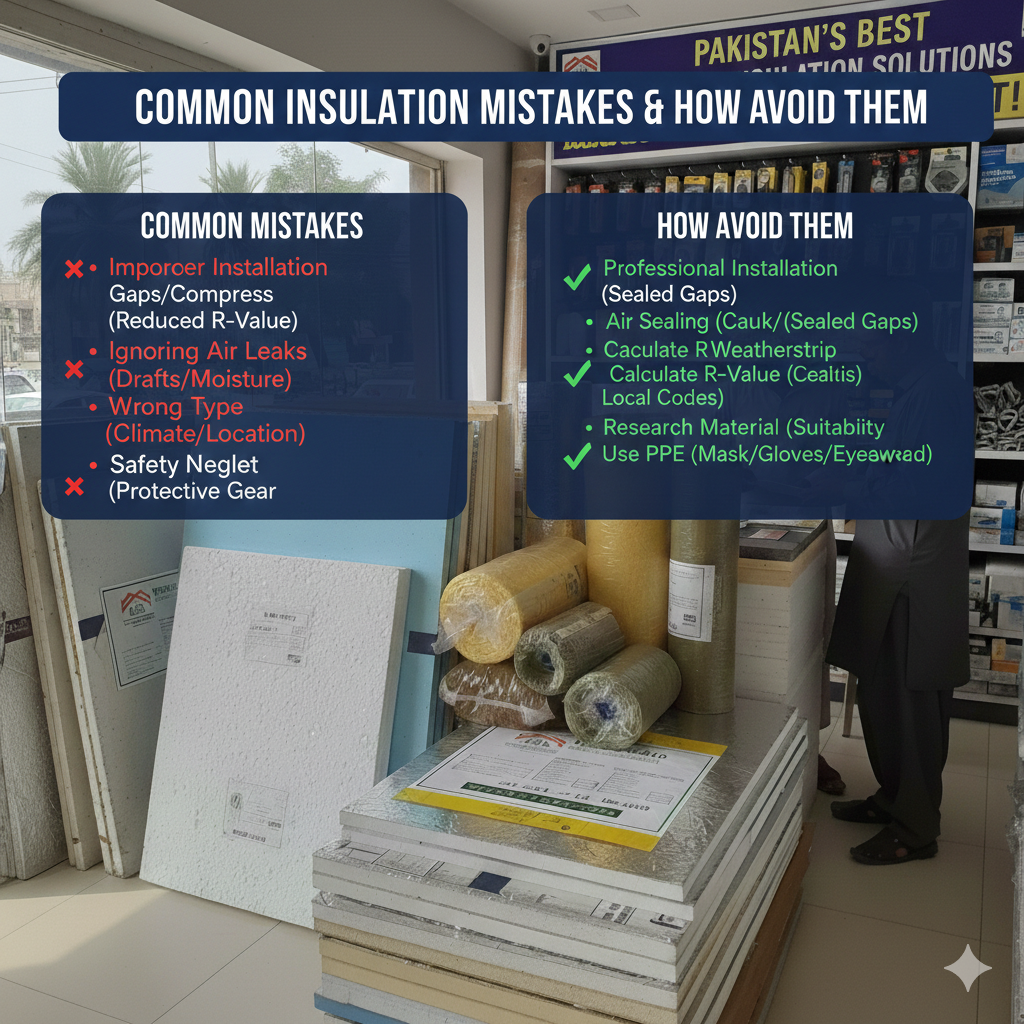

When selecting 12mm insulation, consider:

- Quality and density of material

- Proper installation techniques

- Compatibility with existing structure

- Supplier reliability

Correct installation is essential to ensure the insulation performs as expected.

Final Thoughts

Understanding the 12mm thermal insulation price in Pakistan helps homeowners and builders make informed decisions. Whether you choose jumbolon or thermocol, 12mm insulation sheets offer a cost-effective way to reduce heat and improve comfort in Pakistan’s climate.

By comparing material options, city-wise pricing, and application needs, you can select an insulation solution that delivers both performance and value.

FAQ’S

12mm thermal insulation is suitable for light to moderate heat control, especially in homes, apartments, and renovation projects. For areas with extreme heat exposure, thicker insulation may provide better performance.

12mm jumbolon sheets are flexible and moisture-resistant, while thermocol sheets are rigid and more affordable. The choice depends on application area, budget, and installation method.

Yes, even 12mm insulation reduces heat transfer, which lowers indoor temperatures and decreases the load on air conditioning systems, helping reduce electricity consumption.

12mm insulation is commonly used in ceilings, walls, office partitions, shops, and small commercial spaces where thicker insulation is not feasible.