Choosing the right insulation material is one of the most important decisions in construction, especially in regions with extreme temperatures. In Pakistan, Thermopore, XPS, and Jumbolon are among the most commonly used insulation materials. This blog presents a detailed comparison of Thermopore vs XPS vs Jumbolon, helping homeowners, contractors, and builders understand which option suits their needs best.

Why Comparing Insulation Materials Matters

Different insulation materials perform differently depending on heat resistance, moisture exposure, durability, and cost. Many people ask thermopore vs xps vs jumbolon which is better, but the answer depends on application, budget, and performance expectations.

A clear comparison helps avoid long-term energy loss and unnecessary maintenance costs.

What Is Thermopore Insulation?

Thermopore is a lightweight insulation material made from expanded polystyrene. It is commonly used for basic thermal insulation in walls and ceilings.

Key Features of Thermopore

- Lightweight and easy to install

- Provides basic thermal insulation

- Commonly available in sheet form

Thermopore sheet insulation is often chosen for low-budget projects where moderate insulation performance is acceptable.

What Is XPS Insulation?

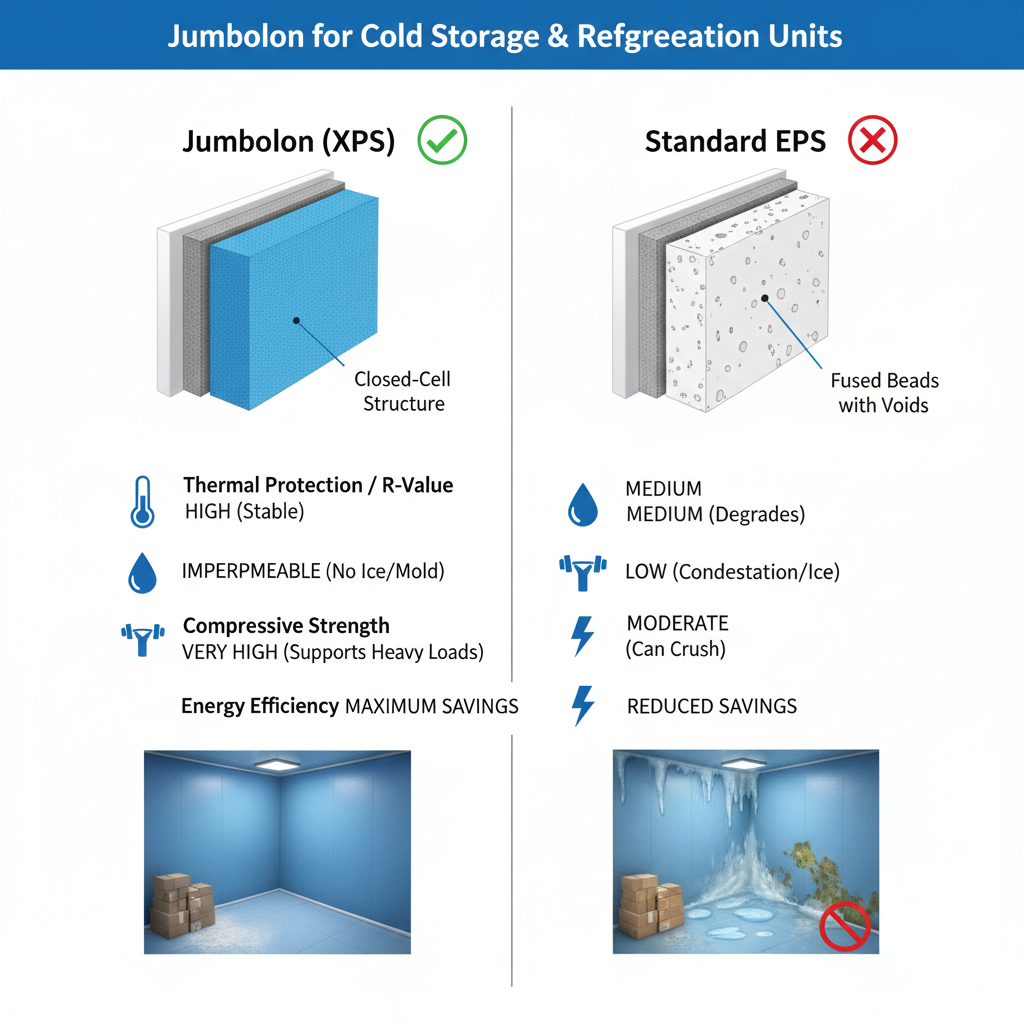

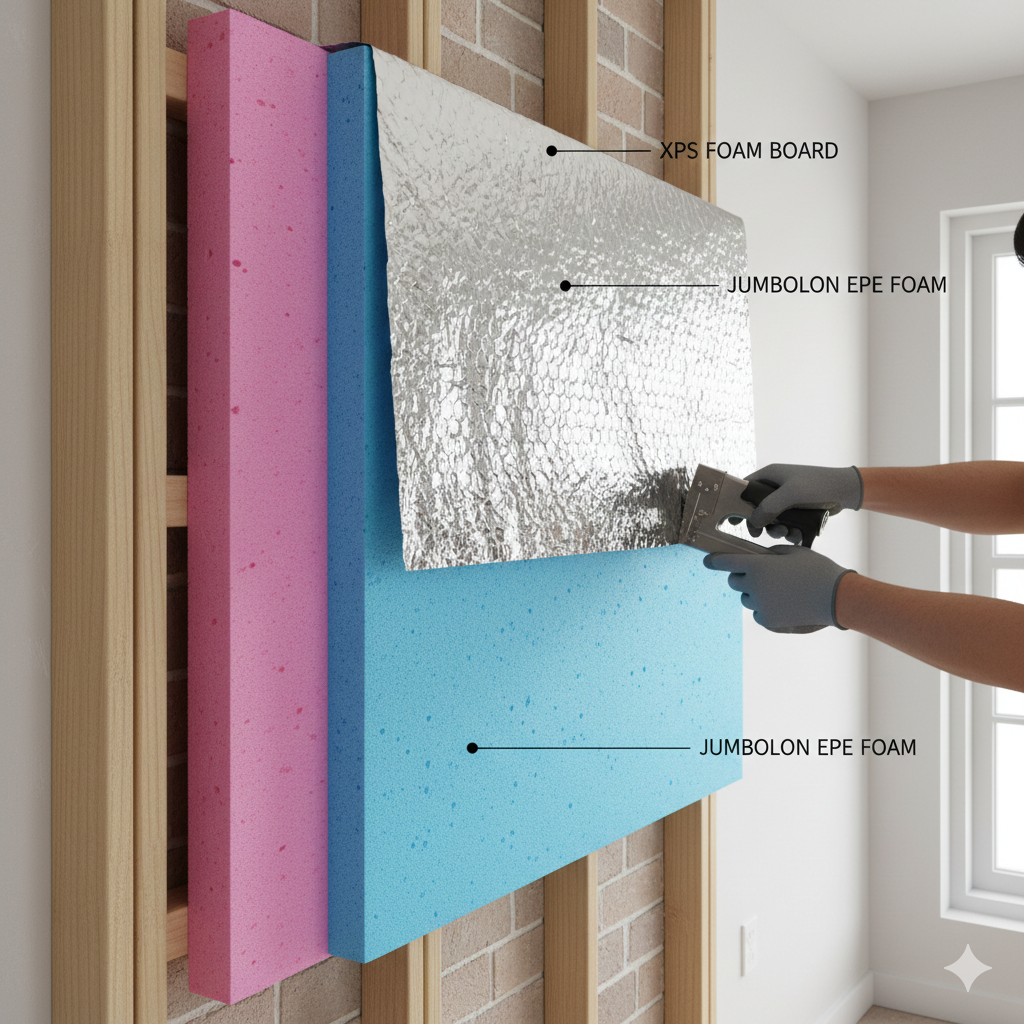

XPS (Extruded Polystyrene) is a high-density insulation board designed for superior thermal resistance and moisture control. It is widely used in roofs, foundations, and floors.

Why XPS Is Considered Premium

- Higher compressive strength

- Excellent moisture resistance

- Long service life

In most professional applications, XPS outperforms Thermopore and flexible foams.

What Is Jumbolon Insulation?

Jumbolon is a closed-cell polyethylene foam insulation commonly used for thermal and acoustic purposes. It is flexible, lightweight, and easy to apply in residential and commercial buildings.

The comparison of jumbolon vs thermopore often comes down to flexibility and ease of installation versus rigidity.

Performance Comparison: Thermopore vs XPS vs Jumbolon

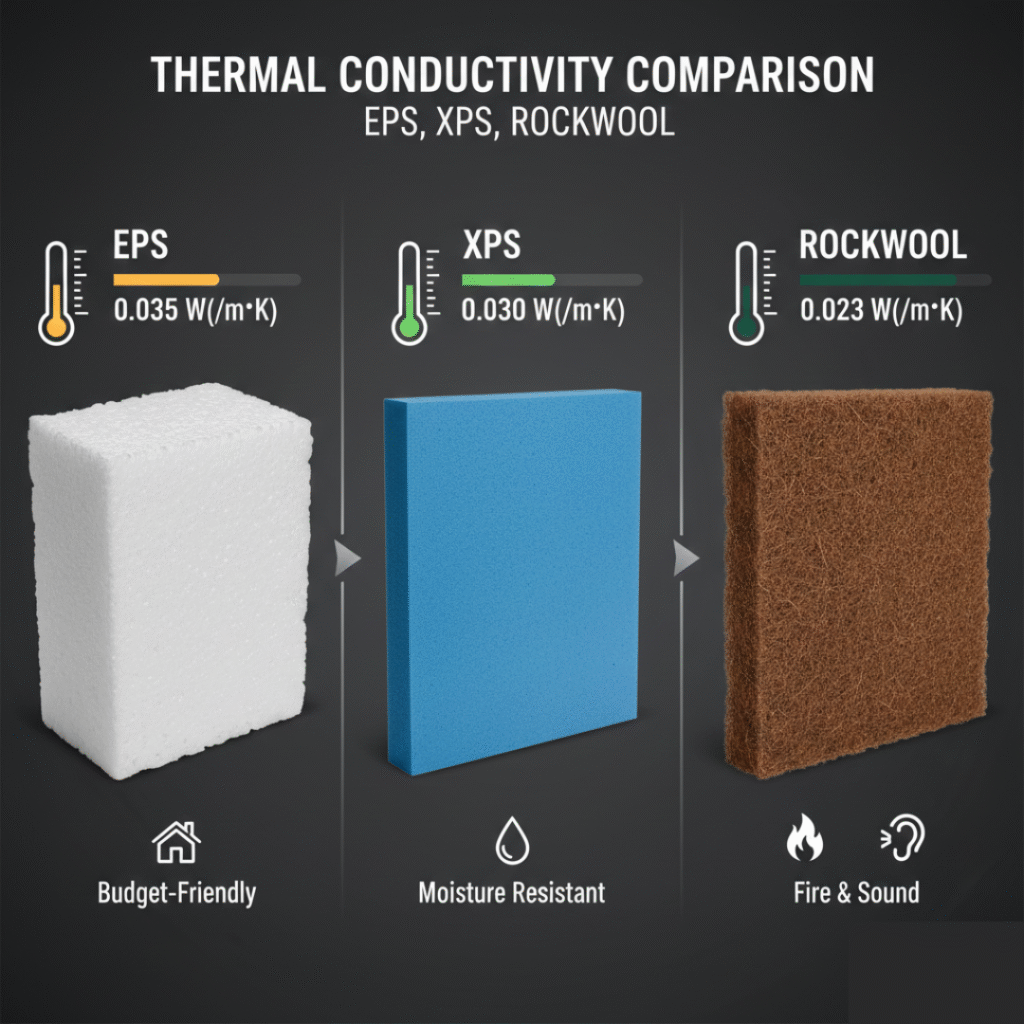

Thermal Insulation Performance

- XPS offers the highest thermal resistance

- Jumbolon provides moderate insulation with flexibility

- Thermopore delivers basic thermal protection

This performance gap is why many ask thermopore vs xps vs jumbolon which is better for long-term use.

Moisture Resistance

- XPS resists water absorption extremely well

- Jumbolon performs well in humid environments

- Thermopore may absorb moisture over time

Durability and Strength

- XPS is structurally strong and load-bearing

- Jumbolon is flexible but not load-bearing

- Thermopore is fragile and prone to breakage

Price Comparison in Pakistan

Jumbolon Price in Pakistan

The jumbolon price in pakistan varies depending on thickness, density, and brand. It is generally considered affordable and suitable for residential insulation projects.

Jumbolon Sheet Price in Pakistan

The jumbolon sheet price in pakistan depends on sheet thickness and roll size. Thicker sheets naturally cost more but offer better insulation.

12mm Jumbolon Sheet Price in Pakistan

The 12mm jumbolon sheet price in pakistan is commonly searched because this thickness is widely used for roof and ceiling insulation due to its balance between cost and performance.

Thermopore Price

Thermopore price is usually lower than both XPS and Jumbolon, making it a budget-friendly option for short-term or low-demand insulation needs.

Overall Jumbolon Price Comparison

When evaluating overall jumbolon price, it sits between Thermopore and XPS, offering a good balance of flexibility, insulation, and affordability.

Best Use Cases for Each Material

When to Use Thermopore

- Low-budget construction

- Temporary insulation needs

- Non-load-bearing areas

Use of XPS

- Roof insulation

- Foundations and floors

- Long-term energy-efficient buildings

When to Use Jumbolon

- Residential roofs and ceilings

- Acoustic insulation

- Areas requiring flexible insulation

Final Verdict: Which One Should You Choose?

There is no single answer to thermopore vs xps vs jumbolon which is better. The right choice depends on your specific needs:

- Choose XPS for maximum durability and thermal performance

- Choose Jumbolon for flexible, cost-effective insulation

- Choose Thermopore for basic, low-cost applications

Understanding the difference between jumbolon vs thermopore and comparing them with XPS ensures you invest in the right insulation solution.

Conclusion

Comparing Thermopore vs XPS vs Jumbolon helps builders and homeowners make informed insulation decisions. While XPS delivers premium performance, Jumbolon offers flexibility and affordability, and Thermopore remains a basic insulation choice for budget projects.

Selecting the right material today can lead to better comfort, lower energy bills, and long-term savings.

FAQ’S

The better option depends on usage. XPS offers the best thermal performance and durability, Jumbolon provides flexible and cost-effective insulation, while Thermopore is suitable for basic and low-budget applications.

Jumbolon is flexible and moisture-resistant, while Thermopore is rigid and more fragile. Jumbolon is better for roofs and ceilings, whereas Thermopore is mainly used for basic wall insulation.

Yes, XPS is generally better than Thermopore for roofs because it has higher compressive strength, better moisture resistance, and longer service life.

Jumbolon price in Pakistan depends on thickness, density, sheet size, and brand. Thicker sheets usually provide better insulation and cost more.

The jumbolon sheet price in Pakistan varies by thickness and quality. Standard sheets are more affordable, while thicker insulation sheets cost slightly higher.

The 12mm jumbolon sheet price in Pakistan is popular because this thickness offers a good balance between insulation performance and affordability for residential roofs.

Thermopore can be used for short-term or low-load applications. For long-term durability and higher insulation performance, XPS or Jumbolon is generally recommended.

XPS performs best in moisture-prone areas due to its closed-cell structure, while Jumbolon also performs well. Thermopore may absorb moisture over time.